Abstract

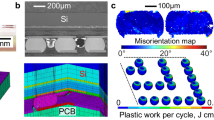

A novel experimental configuration was devised to measure the evolution of the deformation field and the corresponding toughness in solder joints for microelectronic packaging. The utilized material system comprised a ductile layer of tin-based solder encapsulated within relatively hard copper shoulders. The experimental configuration provided pure shear state within the constrained solder layer. Different Pb/Sn compositions were tested with grain size approaching the film thickness. The in-plane strain distribution within the joint thickness was measured by a microscopic digital image correlation system. The toughness evolution within such highly gradient deformation field was monitored qualitatively through a two-dimensional surface scan with a nanoindentor. The measurements showed a highly inhomogeneous deformation field within the film with discreet shear bands of concentrated strain. The localized shear bands showed long-range correlations of the order 2–3 grain diameters. A size-dependent macroscopic response on the layer thickness was observed. However, the corresponding film thickness was approximately 100–1000 times larger than those predicted by nonlocal continuum theories and discreet dislocation.

Similar content being viewed by others

References

J.W. Morris, F.J.L. Goldstein, and Z. Mei, in The Mechanics of Solder Alloy Interconnects, edited by D. Frear, H. Morgan, S. Burchett, and J. Lau (Chapman and Hall, New York, 1994).

C. Basaran and J. Jiang, Mech. Mater. 34, 349 (2002)

G.E. Dieter, Mechanical Metallurgy (McGraw-Hill, New York, 1981).

J.P. Ranieri, F.S. Lauten, and D.H. Avery, J. Electron. Mater. 24, 1419 (1995).

A.P. Green, J. Mech. Phys. Solids 2, 197 (1954).

A. Needleman, Acta Metall. 48, 105 (2000).

The Mechanics of Solder Alloy Interconnects, edited by D. Frear, H. Morgan, S. Burchett, and J. Lau (Chapman and Hall, New York, 1994).

V. Tvergaard and J. Hutchinson, J. Mech. Phys. Solids 40, 1377 (1992).

Surface Displacement Analysis User Manual (Instron, Canton, MA, 1997).

E.O. Brigham, The Fast Fourier Transform (Prentice-Hall, Englewood Cliffs, NJ, 1974).

D.J. Chen, F.P. Chiang, Y.S. Tan, and H.S. Don, Appl. Opt. 32, 1839 (1993).

A-F. Bastawros and R. McManuis, Exp. Tech. 22, 35 (1998).

A-F. Bastawros, H. Bart-Smith, and A.G. Evans, J. Mech. Phys. Solids 48, 301 (2000).

D. Tabor, Hardness of Metals (Oxford University Press, Oxford, U.K., 1951).

A-F. Bastawros and K-S. Kim, in Fracture and Ductile vs. Brittle Behavior, edited by G.E. Beltz, R.L. Blumberg Selinger, M.P. Marder, and K-S. Kim (Mater. Res. Soc. Symp. Proc. 539, Pittsburgh, PA, 1998), p. 251.

A-F. Bastawros and K-S. Kim, J. Mech. Phys. Solids 48, 67 (2000).

W. Callister, Material Science and Engineering, An Introduction (John Wiley & Sons, New York, 1999).

H.P. Meissner and E.W. Merrill, ASTM Bull. 151, 80 (1948).

Adhesion and Adhesives Science and Technology, edited by A.J. Kinloch (Chapman and Hall, London, U.K., 1987), p. 211.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Antoniou, A., Bastawros, A.F. Deformation characteristics of tin-based solder joints. Journal of Materials Research 18, 2304–2309 (2003). https://doi.org/10.1557/JMR.2003.0323

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2003.0323