Abstract

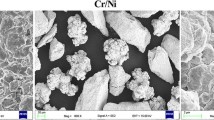

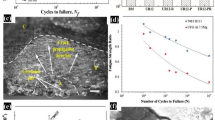

Aluminum and its alloys show poor tribological properties. Oxygen plasma source ion implantation is an emerging technology for the improvement of the surface mechanical properties of these materials. We found an optimum O ion dose, corresponding to 35 at.% O, for which we were able to obtain nanohardness enhancements by factors of 2× and 3× for pure and alloyed (AA7075) Al, respectively. Nanoscratch test results showed reductions in the scratch depths and the friction coefficients by nearly the same factors. It is also important to control the process temperature (∼160 °C). These improvements are due to the formation of a smooth, stiff, but nonbrittle metal–oxide (Al–Al2O3) nanocomposite.

Similar content being viewed by others

References

Metals Handbook, 8th ed., edited by T. Lyman (ASM, Metals Park, OH, 1961), Vol. 1, p. 917.

Smithells Metals Reference Book, 6th ed., edited by E.A. Brandes (Butterworths, London, 1983), Chap. 22.

R.S. Bourcier, S.M. Myers, and D.H. Polonis, Nucl. Instrum. Methods B 44, 278 (1990).

D. Popovici, M. Bolduc, B. Terreault, A.H. Sarkissian, B.L. Stansfield, R.W. Paynter, and D. Bourgoin, J. Vac. Sci. Technol. A 17, 1996 (1999).

M. Bolduc, D. Popovici, and B. Terreault, Surf. Coat. Technol. 138, 125 (2001).

J.R. Conrad, J.L. Radtke, R.A. Dodd, and F.J. Worzola, J. Appl. Phys. 62, 4591 (1987).

M. Bolduc and B. Terreault, Appl. Phys. Lett. 82, 895 (2003).

R.K. Hart, Proc. R. Soc. A 236, 68 (1956).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 7, 1564 (1992).

E.W. Gerberich, W. Yu, D. Kramer, A. Strojny, D. Bahr, E. Lilleoden, and J. Nelson, J. Mater. Res. 13, 421 (1998).

Support Note No. 225, Rev. F (Digital Instruments Inc., Santa Barbara, CA, 1998).

J-A. Ruan and B. Bhushan, J. Tribol. 116, 378 (1994).

B. Du, M.R. Vanlandingham, Q. Zang, and T. He, J. Mater. Res. 16, 1487 (2001).

M. Bolduc, B. Terreault, A. Reguer, E. Shaffer, and R.G. St-Jacques (unpublished).

J.I. Gersten and F.W. Smith, The Physics and Chemistry of Materials (Wiley, New York, 2001), Chap. 21; Web supplement, ftp://ftp.wiley.com/public/sci_tech_med/materials p. W381.

D. Kramer, H. Huang, M. Kriese, J. Robach, J. Nelson, A. Wright, D. Bahr, and W.W. Gerberich, Acta Mater. 47, 333 (1998).

J. Jagielski, A. Piatkowska, P. Aubert, C. Legrand-Buscema, C. Le Paven, G. Gawlik, J. Piekoszewski, and Z. Werner, Vacuum 70, 147 (2003).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bolduc, M., Terreault, B., Reguer, A. et al. Optimum tribological improvement of aluminum using oxygen plasma source ion implantation. Journal of Materials Research 18, 1761–1764 (2003). https://doi.org/10.1557/JMR.2003.0244

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2003.0244