Abstract

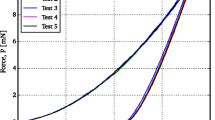

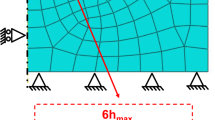

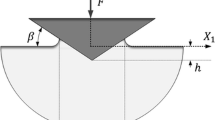

Extensive indentation tests were conducted for nineteen different engineering materials ranging from brittle to ductile materials, and including hard ceramics, ductile metals, and a soft organic polymer. Three tetrahedral pyramid indenters with specific face angles β [shallow pyramid (β = 10°), Vickers (β = 22°), and sharp pyramid (β = 40°) indenters] were used. All the materials tested were subjected to the quadratic load P and penetration depth h relationship P = k1h2 on loading, and most of the tested materials to the quadratic unloading relationship of P = k2(h − hr)2 with the residual depth hr after a complete unload. To determine the contact area at peak indentation load, a specially designed depth-sensing instrument was constructed, on which the contact behavior during loading/unloading was examined by through thickness observation of transparent specimens. All the characteristic indentation parameters were investigated on the basis of simple elastoplastic model, and correlated well with the nondimensional strain E′ tan β/H, in which the elastic modulus E′ was a measure for elasticity, true hardness H was a measure for plasticity, and the inclined face angle β characterized the indenter. The ratio of the conventional Meyer hardness HM to the true hardness H of the materials tested ranged from 0.2 to 0.9 as a function of E′ tan β/H. The cavity model suggested that true hardness H is expressed by the yield stress Y through a constraint factor C as H = C · Y with C ≈ 5.

Similar content being viewed by others

References

D. Tabor, Hardness of Metals (Clarendon Press, Oxford, United Kingdom, 1951), Chaps. 4–7.

K.L Johnson, Contact Mechanics (Cambridge University Press, Cambridge, United Kingdom, 1985), Chaps. 3–6.

N.A. Stilwell and D. Tabor, Proc. Phys. Soc. London 78, 169 (1961).

S.I. Bulychev, V.P. Alekhim, M.Kh. Shorshorov, A.P. Ternovskii, and G.D. Shnyrev, Zavod. Lab. 41, 1137 (1975).

B.R. Lawn and V.R. Howes, J. Mater. Sci. 16, 2745 (1981).

J.L. Loubet, J.M. Georges, and G. Meille, in Microindentation Techniques in Materials Science and Engineering, edited by P.J. Blay and B.R. Lawn (ASTM STP889, Philadelphia, PA, 1986), p. 72.

M.F. Doerner and W.D. Nix, J. Mater. Res. 1, 601 (1986).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 7, 1564 (1992).

G.M. Pharr, W.C. Oliver, and F.R. Brotzen, J. Mater. Res. 7, 613 (1992).

J.S. Field and M.V. Swain, J. Mater. Res. 8, 297 (1993).

M. Sakai, Acta Metall. Mater. 41, 1751 (1993).

E. Söderlund and D.J. Rowcliffe, J. Hard Mater. 5, 149 (1994).

R.F. Cook and G.M. Pharr, J. Hard Mater. 5, 179 (1994).

S.V. Hainsworth, H.W. Chandler, and T.F. Page, J. Mater. Res. 11, 1987 (1996).

M. Sakai, S. Shimizu, and T. Ishikawa, J. Mater. Res. 14, 1471 (1999).

Y-T. Cheng and C-M. Cheng, Int. J. Solids Struct. 36, 1231 (1999).

M. Sakai, J. Mater. Res. 14, 3630 (1999).

S. Shimizu, T. Yanagimoto, and M. Sakai, J. Mater. Res. 14, 4075 (1999).

A.E. Giannakopoulos and S. Suresh, Scripta Mater. 40, 1191 (1999).

Y-T. Cheng and C-M. Cheng, Surf. Coat. Technol. 133–134, 417 (2000).

M. Sakai and S. Shimizu, J. Non-Cryst. Solids 282, 236 (2001).

X. Chen and J.J. Vlassak, J. Mater. Res. 16, 2974 (2001).

J. Malzbender and G. de With, J. Mater. Res. 17, 502 (2002).

JIS standard B-7735, Vickers hardness test—Calibration of the reference blocks (Japanese Standard Association, 1997).

JIS standard G-4805, High carbon chromium bearing steels (Japanese Standard Association, Tokyo, Japan, 1999).

JIS standard H-3100, Copper and copper alloy sheets, plates, and strips (Japanese Standard Association, 1992).

ISO standard 426-1, Wrought copper-zinc alloys—Chemical composition and forms of wrought products—Part 1: Non-leaded special copper-zinc alloys (International Standardization Organization, 1983).

ISO/DIS standard 683-17, Heat-treated steels, alloy steels and free-cutting steels—Part 17: Ball and roller bearing steels (International Standardization Organization, Geneva, Switzerland, 1997).

R.B. King, Int. J. Solids Struct. 23, 1657 (1987).

J.C. Hay, A. Bolshakov, and G.M. Pharr, J. Mater. Res. 14, 2296 (1999).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sakai, M., Nakano, Y. Elastoplastic load–depth hysteresis in pyramidal indentation. Journal of Materials Research 17, 2161–2173 (2002). https://doi.org/10.1557/JMR.2002.0318

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2002.0318