Abstract

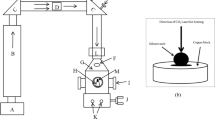

An Al2O3–5 at% SiO2 specimen was levitated in an Aero-Acoustic Levitation apparatus and then melted when a continuous-wave CO2 laser beam heating system was incorporated. The sample can be highly undercooled when decreasing the laser power. Rapid solidification by splat quenching can be realized at defined temperatures, using well-polished copper as chilling anvils. Microstructure transition from nonfaceted colony to strong faceted dendrites was observed when the melt was quenched at ΔT = 50 K, indicating that a kinetic contribution for roughening the microstructure may be significant for the morphology transition. The impacting, spreading, and solidifying processes were analyzed on the basis of microstructure observation. The additional undercooling was suggested to vary per an exponential relation with distance when the kinetic effect was taken into account. The nucleation behavior was also discussed according to the proposed additional undercoolings to demonstrate the difference in nucleation population at various regions. When the melt undercooling increases to 190 K, a double-phase structure with small polycrystalline inclusion embedded into amorphous matrix was obtained. The continuous cooling transformation profile was proposed to account for the phase selection upon quenching. The present observation and suggested model for acquiring high additional undercoolings are useful in elucidating the work of others.

Similar content being viewed by others

References

K. Klement, R.H. Willens, and P. Duwez, Nature 187, 869 (1960). For an excellent review on metallic glass, one can refer to A. Lindsay Greer, Science, 267, 1947 (1995).

D. Shechtman, I. Blech, D. Gratias, and J.W. Cahn, Phys. Rev. Lett. 53, 1951 (1984).

C.H. Smith, in Rapidly Solidified Alloys: Processes, Structures, Properties, Applications, edited by Howard H. Liebermann (Marcel Dekker, Inc., New York, 1993), p. 617.

R.K. Mishra, J. Appl. Phys. 64, 5562 (1988).

A. Zaluska, X. Yan, Z. Altounian, J.O. Strom-Olsen, R. Allem, and G. L’Esperance, J. Mater. Res. 6, 724 (1991).

J.A. Sarreal and C.C. Koch, Mater. Sci. Eng. A A136, 141 (1991).

A. Yavari and J.L. Verger-Gaugry, J. Mater. Sci. 23, 3383 (1988).

Y. Abe, Master Thesis, The University of Tokyo, 2000.

T. Volkmann, W. Loeser, and D.M. Herlach, Metall. Mater. Trans. A 28A, 453 (1997).

W. Hofmeister, R.J. Bayuzick, G. Trapaga, D.M. Matson, and M.C. Flemings, in Solidification 1998, edited by S.P. Marsh, J.A. Dantzig, R. Trivedi, W. Hofmeister, M.G. Chu, E.J. Lavernia, and J-H. Chun, (The Minerals, Metals & Materials Society, Warrendale, PA, 1998), p. 375.

P.T. Sarjeant and R. Roy, J. Appl. Phys. 38, 4540 (1967).

S. Sömiya, M. Ishigame, and M. Yoshimura, Kou-neisu Gijutsu, (Uchida-Rokakuho Pub., Tokyo, Japan, 1987), p. 59.

T. Ando and Y. Shiohara, J. Am. Ceram. Soc. 74, 410 (1991).

T. Bhatia, K. Chattopadhyay, and V. Jayaram, J. Am. Ceram. Soc. 84, 1873 (2001).

J.K. Richard Weber, J.J. Felten, and P.C. Nordine, Rev. Sci. Instrum. 67, 522 (1996).

J.K. Richard Weber, D. Scott Hampton, D.R. Merkley, C.A. Rey, M.M. Zatarski, and P.C. Nordine, Rev. Sci. Instrum. 65, 456 (1994).

K. Nagashio and K. Kuribayashi, Acta Mater. 49, 1947 (2001).

K. Nagashio, W.H. Hofmeister, D.E. Gustafson, A. Altgilbers, R.J. Bayuzick, and K. Kuribayashi, J. Mater. Res. 16, 138 (2001).

G.A. Bertero, W.H. Hofmeister, M.B. Robinson, and R.J. Bayuzick, Metall. Trans. A 22A, 2713 (1991).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, M., Nagashio, K. & Kuribayashi, K. Microstructure formation and phase selection in the solidification of Al2O3–5 at% SiO2 melts by splat quenching. Journal of Materials Research 17, 2026–2032 (2002). https://doi.org/10.1557/JMR.2002.0300

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2002.0300