Abstract

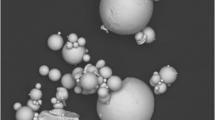

In this work, Fe2Mo intermetallic powder, produced by H2 gas reduction of Fe2MoO4 was characterized by techniques like x-ray diffraction (XRD) and transmission electron microscopy (TEM). The TEM studies confirmed the presence of nano- and microcrystalline grains of Fe2Mo. The above powders when compressed uniaxially showed a logarithmic relation with “relative density”, δr, of the compacts. The multiple compaction mechanisms were analyzed by Kawakita’s and Balshin’s models. Vickers hardness number, VHN, was found to increase linearly with δr of the compacts. The hardness of Fe2Mo intermetallic when δr = 1 was estimated as 343 VHN. Using Tabor’s analysis, the yield strength of Fe2Mo was found to be about 1100 MPa. This value was further confirmed from the details of relative broadening (112) Bragg peak of Fe2Mo obtained from XRD analyses of Fe2Mo at different compaction pressures.

Similar content being viewed by others

References

C.T. Liu and J.O. Stiegler, Science 26, 636 (1984).

I. Baker and P.R. Munroe, J. Met. 40, 28 (1988).

E.M. Schulson and D.R. Barker, Scr. Metall. 17, 519 (1983).

A. Inoue, H. Tomioka, and T. Masumoto, Metall. Trans. A 14, 1367 (1983).

R. Morales, I. Arvanitidis, Du Sichen, and S. Seetharaman, Metall. Mater. Trans. (2002, in press).

E.Y. Gutmanas, Powder Metall. Int. 12, 178 (1980).

J.L. Brackpool, Modern Developments in Powder Metallurgy (Plenum, New York, 1971), pp. 423–435.

J.J. Benbow, Enlargement and Compaction of Particulate Solids (Butterworth, Boston, MA, 1983), pp. 167–168.

K. Kawakita, J. Jpn. Soc. Powder Metall. 16, 236 (1963).

P.J. James, Powder Metall. Int. 4, 193 (1972).

B. Marinkovic and N. Nikolic, J. Min. Metall. B 36, 29 (2000).

L.T. Kuhn, R.M. McMeeking, and F.F. Lange, J. Am. Ceram. Soc. 74, 682 (1991).

J. Wulff, Powder Metallurgy (The American Society for Metals, Cleveland, OH, 1942). pp. 500–501.

D. Tabor, J. Inst. Met. 79, 1 (1951).

J.R. Cahoon, W.H. Broughton, and A.R. Kutzak, Metall. Trans. 2, 1979 (1971).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Morales, R., Seetharaman, S. & Agarwala, V. Mechanical and structural characterization of uniaxially cold-pressed Fe2Mo powders. Journal of Materials Research 17, 1954–1959 (2002). https://doi.org/10.1557/JMR.2002.0289

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2002.0289