Abstract

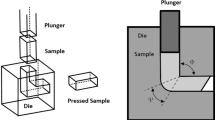

Strain rate is an important factor in plastic deformation because it determines the constitutive behavior of rate sensitive materials, e.g., dislocation density and flow stress evolution, deformation heat generation, etc. In the present study, the strain rate of workpiece materials during equal-channel angular pressing (ECAP) was evaluated by a geometric approach. The results were compared to those of the finite element analyses of a model ideally plastic material with various mesh sizes. The derived equation for strain rate is in reasonably good agreement with the results of the finite element method. The effects of the die geometry (a channel angle and a corner angle) were investigated. The strain rate during ECAP increases with punch speed and decreases with die channel angle, die corner angle, and the width of the workpiece. The relation obtained can be used for analytical calculations of the deformation, thermal, and microstructural evolution behavior of materials during ECAP. In particular, the size of the deforming zone and the effect of the finite element size are discussed.

Similar content being viewed by others

References

E. Nes, Prog. Mater. Sci. 41, 129 (1998).

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov, Prog. Mater. Sci. 45, 103 (2000).

V.M. Segal, V.I. Reznikov, A.E. Drobyshevkiy, and V.I. Kopylov, Russ. Metall. (English trans.) 1, 99 (1981).

V.M. Segal, Mater. Sci. Eng. A 197, 157 (1995).

H.S. Kim, Mater. Sci. Eng. A 315, 122 (2001, in press).

H.S. Kim, M.H. Seo, and S.I. Hong, Mater. Sci. Eng. 291A, 86 (2001).

Y. Iwahashi, J. Wang, Z. Horita, M. Nemoto, and T.G. Langdon, Scripta Mater. 35, 143 (1996).

H.J. Cui, R.E. Goforth, and K.T. Hartwig, JOM-e 50 http://www.tms.org/pubs/Journals/JOM/9808/Cui/ (1998).

D.N. Lee, Scripta Mater. 43, 115 (2000).

P.B. Prangnell, C. Harris, and S.M. Roberts, Scripta Mater. 37, 983 (1997).

L. Zuyan and W. Zhongjin, J. Mater. Proc. Technol. 94, 193 (1999).

E. Srinivasan, Scripta Mater. 44, 91 (2001).

S.L. Semiatin, D.P. Delo, and E.B. Shell, Acta Mater. 48, 1841 (2000).

J.R. Bowen, A. Gholinia, S.M. Roberts, and P.B. Prangnell, Mater. Sci. Eng. A 287, 87 (2000).

D.P. DeLo and S.L. Semiatin, Metall. Mater. Trans. 30A, 1391 (1999).

S.L. Semiatin, P.B. Berbon, and T.G. Langdon, Scripta Mater. 44, 135 (2001).

S.L. Semiatin, V.M. Segal, R.E. Goforth, N.D. Frey, and D.P. DeLo, Metall. Mater. Trans. 30A, 1425 (1999).

H.S. Kim, Mater. Trans. JIM 42, 344 (2001).

P.B. Berbon, M. Furukawa, Z. Horita, M. Nemoto, and T.G. Langdon, Metall. Mater. Trans. 30A, 1989 (1999).

H.S. Kim, S.I. Hong, and M.H. Seo, J. Mater. Res. 16, 856 (2001).

Hibbitt, Karlsson & Sorensen Inc., ABAQUS 5.8, Rhode Island (1999).

D. Yamaguchi, Z. Horita, M. Nemoto, and T.G. Langdon, Scripta Mater. 41, 791 (1999).

L.E. Cross, Ferroelectrics 76, 241 (1987).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, H.S. Evaluation of Strain Rate During Equal-channel Angular Pressing. Journal of Materials Research 17, 172–179 (2002). https://doi.org/10.1557/JMR.2002.0026

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2002.0026