Abstract

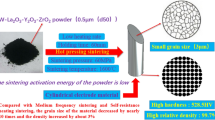

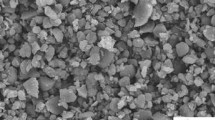

Commercial micrometer Al2O3 powder was sintered at 1550 °C under a mechanical pressure of 30 MPa by pulse electric current sintering (PECS). Microstructure observation was performed on polished, thermal-etched cross sections parallel to the direction of mechanical pressure. Platelike Al2O3 grains formed when the powder was heated at a heating rate of 5 °C/min, while a heating rate of 200 °C/min resulted in equiaxed grains. These results indicated that PECS is an effective approach to hinder grain growth by application of a higher heating rate. However, Al2O3 grains at the upper edge were larger than those at the side edge of the samples in both cases. It implied that there were different temperatures at the upper edge and the side edge of the Al2O3 powder compacts during the PECS process.

Similar content being viewed by others

References

Y. Kinemuchi, H. Funakoshi, and K. Ishizaki, J. Ceram. Soc. Jpn. 106, 535 (1998).

D. S. Perera, M. Tokita, and S. Moricca, J. Eur. Ceram. Soc. 18, 401 (1998).

T. Nishimura, M. Mitomo, H. Hirotsuru, and M. Kawahara, J. Mater. Sci. Lett. 14, 1046 (1995).

Y. S. Kang, Y. Noda, L. D. Chen, K. Kisara, and N. Niino, in Proceedings of the 4th International Symposium on Functionally Graded Materials, edited by I. Shiota and Y. Miyamoto (Tsukuba, Japan, 1996), p. 569.

N. Murayama, Ceramics 32, 445 (1997).

Y. Kinemuchi and K. Ishizaki, in Proceedings of the 22nd Annual Cocoa Beach Conference and Exposition On Composites, Advanced Ceramics, Materials and Structures, edited by the Am. Ceram. Soc., Cocoa Beach, FL (Am. Ceram. Soc., Westerville, OH, 1998), paper No. SI–016.

M. Yoshimura, T. Ohji, T. Sekkino, and K. Niihara, J. Mater. Sci. Lett. 17, 1389 (1998).

H. Kawaoka, Y-H. Choa, and K. Niihara, Key Eng. Mater. 161–163, 225 (1999).

M. Yoshimura, T. Ohji, M. Sando, Y-H. Choa, T. Sekkino, and K. Niihara, Mater. Lett. 38, 18 (1999).

M. Omori and T. Hirai, New Ceram. 7, 23 (1994).

O. Yanagisawa, T. Hatayama, and K. Matsugi, Mater. Jpn. 33, 1489 (1994).

S. H. Risbud, C-H. Shan, A. K. Mukherjee, M. J. Kim, J. S. Bow, and R. A. Holl, J. Mater. Res. 10, 237 (1995).

M. Tokita, Functionally Graded Materials 1998, edited by W. A. Kaysser (Trans. Tech. Publications, Switzerland, 1999), p. 83.

T. Nage, M. Yokota, and M. Nose, J. Jpn. Soc. Powder Powder Metall. 45, 169 (1998).

S. W. Wang, L. D. Chen, Y. S. Kang, and T. Hirai, J. Mater. Sci. Lett. 18, 1119 (1999).

S. W. Wang, L. D. Chen, and T. Hirai, J. Mater. Res. 15, 982 (2000).

H. P. Cahoon and C. J. Christensen, J. Am. Ceram. Soc. 39, 337 (1956).

Huesup Song and R. L. Coble, J. Am. Ceram. Soc. 73, 2077 (1990).

T. Koyama, A. Nishiyama, and K. Niihara, J. Mater. Sci. 28, 5953 (1993).

S. A. Nightingale, H. K. Worner, and D. P. Dunne, J. Am. Ceram. Soc. 80, 394 (1997).

H. Tomino, H. Watanabe, and Y. Kondo, J. Jpn. Soc. Powder Powder Metall. 44, 974 (1997).

J. F. Roy, M. Descemond, C. Brodhag, and F. Thevenot, J. Eur. Ceram. Soc. 11, 325 (1993).

G.A. Slack, R.A. Tanzilli, R.O. Pohl, and J.W. Vandersande, J. Phys. Chem. Solids 48, 641 (1987).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, S.W., Chen, L.D., Hirai, T. et al. Formation of Al2O3 grains with different sizes and morphologies during the pulse electric current sintering process. Journal of Materials Research 16, 3514–3517 (2001). https://doi.org/10.1557/JMR.2001.0482

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2001.0482