Abstract

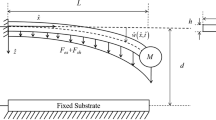

Typical microelectromechanical systems (MEMS) devices and packages are composed of micron-scaled structures. Experimental investigations on the effect of size on the deformation behavior of simple structures have shown that the deformation behavior of metals and polymers is size dependent. The size dependence in small structures is attributed to the contribution of nonnegligible strain gradients. In this work, torsion and bending of micron-sized rods and plates were analyzed by using a two-parameter model of strain-gradient plasticity. Microrod torsion and microplate bending experimental data were analyzed to determine the magnitude of the strain-gradient material parameters. The parametric analyses showed that conventional analysis is applicable only when the size of the structure is significantly larger than the material parameters, which are typically in the micron range. Strain-gradient analysis of micron-sized rod revealed that the presence of strain gradient increased the torque by three to nine times at the same twist. For MEMS structures with micron-sized features, conventional structural analysis without strain gradient is potentially inadequate, and strain-gradient analysis must be conducted to determine the elastoplastic behavior in the micron scale.

Similar content being viewed by others

References

N.A. Fleck, G.M. Muller, M.F. Ashby, and J.W. Hutchinson, Acta Metall. Mater. 42, 475 (1994).

J.S. St. Iken and A.G. Evans, Acta Mater. 46, 5109 (1998).

W.D. Nix and H. Gao, J. Mech. Phys. Solids 46, 411 (1998).

N.A. Stelmashenko, M.G. Walls, L.M. Brown, and Y.V. Milman, Acta Metall. Mater. 41, 2855 (1993).

Q. Ma and D.R. Clarke, J. Mater. Res. 10, 853 (1995).

W.J. Poole, M.F. Ashby, and N.A. Fleck, Scripta Mater. 34, 599 (1996).

D.C.C Lam and A.C.M. Chong, J. Mater. Res. 14, 3784 (1999).

A.C.M. Chong and D.C.C. Lam, J. Mater. Res. 14, 4103 (1999).

R.A. Toupin, Arch. Ration. Mech. Anal. 11, 385 (1962).

R.D. Mindlin and H.F. Tiersten, Arch. Ration. Mech. Anal. 11, 415 (1962).

W.T. Koiter, Proc. Ned. Akad. Wet. (B) 67, 17 (1964).

R.D. Mindlin, Arch. Ration. Mech. Anal. 16, 51 (1964).

N.A. Fleck and J.W. Hutchinson, J. Mech. Phys. Solids 41, 1825 (1993).

N.A. Fleck and J.W. Hutchinson, Adv. Appl. Mech. 33, 295 (1997).

R.D. Mindlin, Int. J. Solids Struct. 1, 417 (1965).

V.P. Smyshlyaev and N.A. Fleck, J. Mech. Phys. Solids 44, 465 (1996).

K.C. Hwang and T. Inone, Mat. Sci. Res. Int. 4, 227 (1998).

F. Yang, A.C.M. Chong, D.C.C. Lam, and P. Tong (to be submitted) (2000).

H. Gao, Y. Huang, W.D. Nix, and J.W. Hutchinson, J. Mech. Phys. Solids 47, 1239 (1999).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chong, A.C.M., Yang, F., Lam, D.C.C. et al. Torsion and bending of micron-scaled structures. Journal of Materials Research 16, 1052–1058 (2001). https://doi.org/10.1557/JMR.2001.0146

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2001.0146