Abstract

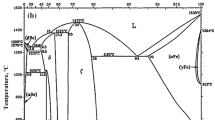

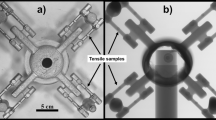

The effects of beryllium (Be) and solution temperature on the morphologies of iron intermetallics, silicon particles, and copper intermetallics, relative to the mechanical properties of 319.0 alloys, were investigated. The experimental results indicated that adding Be to the alloy can raise the Al–Al2Cu eutectic melting temperature, change some plateletlike shape (βndash;Al5FeSi) of iron intermetallics to comparatively harmless Chinese-script morphologies (α–Al8Fe2Si), and reduce the amount and average length of βndash;Al5FeSi platelets. During high-temperature solution treatment (>500 °C), the thinner and smaller the β–Al5FeSi platelets were, the faster they dissolved and fragmented. However, where the solution temperature exceeded the Al–Al2Cu eutectic melting point, the Al–Al2Cu eutectic melted and resulted in an ultrafine eutectic phase on quenching, which deteriorated mechanical properties. The fracture behavior of 319 alloy was affected by the morphologies of the iron intermetallics, silicon particles, and copper intermetallics. Fractographic analysis of tested compact tension specimens revealed that the fracture processes were mainly initiated by void nucleation at β–Al5FeSi platelets as a result of their cracking and decohesion from the matrix. Adding Be to the 319.0 alloy and optimizing the solution temperature could significantly decrease the number of fracture-initiation sites of β–Al5FeSi platelets and improve the tensile properties and fracture toughness.

Similar content being viewed by others

References

A. Couture, AFS Int. Cast Metals J. 6(4), 9 (1981).

L. Backerud, G. Chai, and J. Tamminen, Solidification characteristics of aluminum alloys, AFS/Skan Aluminum, 1990, Vol. 2, pp. 72–86.

L. Anantha Narayanan, F.H. Samuel, and J.E. Gruzleski, Metall. Mater. Trans. A 26A, 2161 (1995).

W. Bonsack, Effects of Minor Alloying Elements on Aluminum Casting Alloys (ASTM Bulletin No. 124, Oct. 1943), pp. 41–51.

L.F. Mondolfo, Aluminum Alloys, Structure and Properties (Butterworths, London, United Kingdom, 1976), p. 760.

S. Murali, K.S. Raman, and K.S.S. Murthy, Cast Metals 6, 189 (1994).

N.A. Belov and T.A. Kurdyumova, Russ. Metall. (Engl. Transl.) 2, 207 (1989).

K.G. Wikle, AFS Trans. 86, 513 (1978).

D.A. Granger, R.R. Sawtell, and M.M. Kersker, AFS Trans. 92, 579 (1984).

Y.H. Tan, S.L. Lee, and Y.L. Lin, Metall. Mater. Trans. A 26A 1195 (1995).

Y.H. Tan, S.L. Lee, and Y.L. Lin, Metall. Mater. Trans. A 26A, 2937 (1995).

P.S. Wang, Y.J. Liauh, S.L. Lee, and J.C. Lin, Mater. Chem. Phys. 53, 195 (1998).

ASTM E602-81, Annual Book of ASTM Standards, Vols. 03.01 and 02.02.

A.M. Samuel, J. Gauthier, and F.H. Samuel, Metall. Mater. Trans. A 27A, 1785 (1996).

J. Gauthier, P.R. Louchez, and F.H. Samuel, Cast Metals 8, 107 (1995).

J. Gauthier, P.R. Louchez, and F.H. Samuel, Cast Metals 8, 91 (1995).

J.G. Kaufman, G.T. Sha, R.F. Kohm, and R.J. Bucci, Cracks and Fracture (ASTM STP 601, ASTM, 1976), pp. 169–190.

ASTM E399-90, Annual Book of ASTM Standards, Vol. 03.01.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, PS., Lee, SL., Lin, JC. et al. ffects of solution temperature on mechanical properties of 319.0 aluminum casting alloys containing trace beryllium. Journal of Materials Research 15, 2027–2035 (2000). https://doi.org/10.1557/JMR.2000.0291

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2000.0291