Abstract

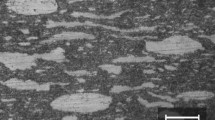

A fully dense in situ Al3Ti–Al2O3 intermetallic matrix composite containing about 30 vol% Al2O3 particles was prepared by combining squeeze casting with combustion synthesis using the chemical reaction between TiO2 and Al. The microstructure of the in situ composite was examined using x-ray diffraction, scanning electron microscopy, and transmission electron microscopy techniques. Compressive behavior of the composite was investigated in the temperature range of 25–600 °C and compared with that of the as-cast Al3Ti alloy. The in situ formed spherical α–Al2O3 particles with a size of 0.2–1 μm were uniformly distributed in the Al3Ti matrix. The grain size of the Al3Ti matrix containing a small amount of Al2Ti precipitate was 2–10 μm. The compressive strength of the in situ composite was about 6–9 times that of the as-cast monolithic Al3Ti alloy and could be maintained at temperatures up to 600 °C. This was mainly attributed to the fine grain size of Al3Ti matrix and the rule of mixture strengthening of Al2O3 particles. The existence of Al2Ti phase and high dislocation density in the matrix also contributed positively to the composite strength.

Similar content being viewed by others

References

T.W. Clyne and P.J. Withers, An Introduction To Metal Matrix Composites, 2nd ed. (Cambridge University Press, Cambridge, 1997).

Z. Fan, H.J. Niu, A.P. Miodownik, T. Saito, and B. Cantor, Key Eng. Mater. 127–131, 423 (1997).

Z. Fan, A.P. Miodownik, L. Chandrasekaran, and M. Ward-Close, J. Mater. Sci. 29, 1127 (1994).

K. Subhash and K. Michael, Mater. Sci. Eng. A 162, 153 (1993).

R.W. Rice, J. Mater. Sci. 26, 6533 (1991).

A. Stanislav and A.S. Nagelberg, J. Am. Ceram. Soc. 75, 447 (1992).

A.K. Kuruvilla, K.S. Prasad, and Y.R. Mahajan, Scripta Metall. Mater. 24, 873 (1990).

I. Gotman and M.J. Koczak, Mater. Sci. Eng. A 187, 189 (1994).

K.M. Lee and I.H. Moon, Mater. Sci. Eng. A 185, 165 (1994).

H. Fukunaga and X.G. Wang, J. Mater. Sci. Lett. 10, 23 (1991).

F. Wagner, D.E. Garcia, A. Krupp, and N. Claussen, J. Eur. Ceram. Soc. 19, 2229 (1999).

R.E. Loehman, K. Ewsuk, and A.P. Tomsia, J. Am. Ceram. Soc. 79, 27 (1996).

M.C. Breslin, J. Ringnalda, A.L. Marasco, G.S. Daehn, and H.L. Fraser, Ceram. Eng. Sci. Proc. 15, 104 (1994).

Z.Y. Ma and S.C. Tjong, Metall. Mater. Trans. 28A, 1931 (1997).

Z.Y. Ma and S.C. Tjong, Mater. Sci. Eng. A 256, 120 (1998).

D.Z. Wang, Z.R. Liu, C.K. Yao, and M. Yao, J. Mater. Sci. Lett. 12, 1420 (1993).

Z.A. Munir and U.A. Tamburini, Mater. Sci. Rep. 3, 277 (1989).

I. Barin and O. Knacke, Thermochemical Properties of Inorganic Substances (Springer-Verlag, New York, 1977).

H.X. Peng, D.Z. Wang, L. Geng, C.K. Yao, and L.G. Wang, Int. J. SHS 5, 285 (1996).

M. Yamaguchi, Y. Umakoshi, and T. Yamane, Philos. Mag. 55, 301 (1987).

Z.L. Wu and D.P. Pope, Acta Metall. Mater. 42, 509 (1994).

J.E. Benci, J.C. Ma, and T.P. Feist, Mater. Sci. Eng. A 192, 38 (1995).

H.X. Peng, D.Z. Wang, L. Geng, and C.K. Yao, Scripta Mater. 37, 199 (1997).

L.F. Mondolfo, Aluminium Alloys: Structure and Properties (Butterworths, London, 1976), p. 385.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Peng, H.X., Fan, Z. & Wang, D.Z. Articles. Journal of Materials Research 15, 1943–1949 (2000). https://doi.org/10.1557/JMR.2000.0280

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2000.0280