Abstract

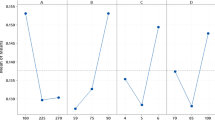

A fractional factorial design was implemented to optimize the experimental conditions for the preparation of ultrafine lanthanum-doped strontium titanate from titanyl acylate precursors. The effects of preparation conditions such as the molar ratio of acetic acid to titanium alkoxide, the water to titanium alkoxide ratio, pH value, the reaction temperature, and stirring speed were systematically studied by using Taguchi orthogonal array design. Results indicated that the effects of the reaction temperature and stirring speed on the reaction were the key variables influencing the average particle size of powders obtained. By combining the optimal settings of the two influential processing variables, it was possible to obtain an ultrafine powder with a particle size of about 340 Å. This was put to a test in the laboratory, and a polycrystalline, narrow size distribution ultrafine SrTiO3 powder that had a particle size of about 380 Å and readily sintered at 1150–1250 °C was obtained.

Similar content being viewed by others

References

T. Tuchiya, T. Kawano, T. Sei, and J. Hatano, J. Ceram. Soc. Jap. 98(8), 743 (1990).

G. Pfaff, J. Mat. Chem. 3, 721 (1993).

H. Salze, P. Odier, and B. Cales, J. Non-Cryst. Solids 82, 314 (1986).

A. Mosset, I. Gautier-Luneau, and J. Galy, J. Non-Cryst. Solids 100, 339 (1988).

D. Hennings, G. Rosentein, and H. Schreinemacher, J. Eur. Ceram. Soc. 8, 107 (1991).

K. Kiss, J. Magder, M.S. Vukasovich, and R.J. Lockhart, J. Am. Ceram. Soc. 59(6), 291 (1966).

C.F. Kao and W.D. Yang, Mat. Sci. Eng. B38, 127 (1996).

C.F. Kao and W.D. Yang, Ceram. Int. 22, 57 (1996).

M.I. Diaz-Guemes, T.G. Carreno, and C.J. Serna, J. Mat. Sci. 24, 1011 (1989).

P.P. Phulé and S.H. Risbud, Adv. Ceram. Mat. 3 (2), 183 (1988).

B. Samuneva, D. Jambazov, D. Lepkova, and Y. Dimitriev, Ceram. Int. 16, 355 (1990).

M.V. Raymond and V.R.W. Amarakoon, J. Am. Ceram. Soc. 73 (5), 1308 (1990).

P.P. Phulé and S.H. Risbud, Mat. Sci. Eng. B3, 241 (1989).

R.L. Perrier, A. Safari, and R.E. Riman, Mater. Res. Bull. 26, 1067 (1991).

C.H. Yang, S.M. Lin, and T.C. Wen, Poly. Eng. Sci. 26, 146 (1994).

S.M. Lin and T.C. Wen, J. Appl. Electrochem. 23, 487–494 (1993).

K.N. Anand, S.M. Bhadkamkar, and R. Moghe, Quality Eng. 7(1), 187 (1994–1995).

Taguchi and Genichi, Tables of Orthogonal Arrays and Linear Graphs (Maruzen, Tokyo, Japan, 1962).

S. Doeuff, M. Henry, C. Sanchez, and J. Livage, J. Non-Cryst. Solids 89, 206 (1987).

Taguchi and Genichi, System of Experimental Design (UNIPUB, New York and American Supplier Institute, Dearborn, MI, 1988) Vols. 1 and 2.

J.M. Wilson and D.L. Coller, U.S. Patent No. 4 670 243 (1987).

P.J. Rose, Taguchi Techniques for Quality Engineering, 2nd ed. (McGraw-Hill, New York, 1996), pp. 75–90.

G.E.P. Box, W.G. Hunter, and J.S. Hunter, Statistics for Experimenters: An Introduction to Design, Data Analysis, and Model Building (Wiley, New York, 1978), pp. 630–640.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Yang, WD., Hsieh, CS. Fractional factorial design applied to optimize experimental conditions for preparation of ultrafine lanthanum-doped strontium titanate powders. Journal of Materials Research 14, 3410–3416 (1999). https://doi.org/10.1557/JMR.1999.0461

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1999.0461