Abstract

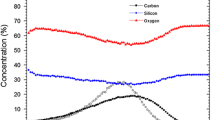

Using direct carbon ion beam deposition, in situ surface modification was performed by an energetic C- beam (400 and 500 eV) prior to amorphous carbon film growth to enhance adhesion of the film. It has been found from high-resolution electron microscopy that the C and Si mixing layer at the interface causes strong adhesion of the film. Electron energy loss spectroscopy was used to investigate chemical states of the C and Si mixing layer at the interface. The carbon composition profile in silicon showed that the thickness of the mixing layer was about 30 nm for 500 eV modification (at 200 °C). Silicon L-edge study at the C/Si interface found C–Si bond formation only at the surface of silicon over 2–3-nm-thick layers. The C–Si bond formation is a function of C- ion impingement energy. The thickness of the bonding layer decreased to less than 1 nm for 400 eV surface modification. When the substrate was modified by a 500-eV C- beam at 800 °C, the thickness of the SiC layer was about 10 nm. C–Si bond formation was enhanced by the supplemental thermal energy.

Similar content being viewed by others

References

M.H. Sohn and S.I. Kim, J. Mater. Res. 14, 2668 (1999).

A. Hoffman, I. Gouzman, and R. Brener, Appl. Phys. Lett. 64(7), 845 (1994).

L. Galan, I. Montero, and F. Rueda, Surf. Coat. Technol. 83, 103 (1996).

K. Yamamoto, Y. Koga, K. Yase, S. Fujiwara, and M. Kubota, Jpn. J. Appl. Phys. 36, L230 (1997).

W.V. Muench and I. Pfaffeneder, Thin Solid Films 31, 39 (1976).

H.S. Kong, J.T. Glass, and R.F. Davis, J. Mater. Res. 4, 204 (1989).

H.P. Liaw and R.F. Davis, J. Electrochem. Soc. 132(3), 642 (1985).

S. Kaneda, Y. Sakamoto, T. Mihara, and T. Tanaka, J. Crystal Growth 81, 536 (1987).

M.H. Sohn, Y.O. Ahn, Y.W. Ko, Y. Park, and S.I. Kim, in Ion-Solid Interactions for Materials Modification and Processing, edited by D.B. Poker, D. Ila, Y-T. Cheng, L.R. Harriott, and T.W. Sigmon (Mater. Res. Soc. Symp. Proc. 396, Pittsburgh, PA, 1996), p. 629.

D.R. McKenzie, S.D. Berger, and L.M. Brown, Solid State Commun. 59(5), 325 (1986).

P.E. Batson, Inst. Phys. Conf. Ser. 117, Sec. 2, 55 (1991).

D.R. McKenzie, J. Bruley, and G.B. Smith, Appl. Phys. Lett. 53(23), 2284 (1988).

W.M. Skiff, R.W. Carpenter, and S.H. Lin, J. Appl. Phys. 58, 3463 (1985).

R.F. Egerton, in Electron Energy Loss Spectroscopy in the Electron Microscope (Plenum Press, 1986).

S.M. Sze, in Semiconductor Devices, Physics and Technology (John Wiley & Sons, 1985).

D.R. McKenzie, N. Savvides, D.R. Mills, R.C. McPhedran, and L.C. Botten, Solar Energy Mater. 9, 113 (1983).

Z. Fang-qing, C. Guang-ha, L. Zhi, and W. Hui-Sheng, J. Non-Cryst. Solids 59/60, 565 (1983).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sohn, M.H., Kim, S.I. & Siangchaew, K. Studies of electron energy loss near edge structure at the interface between Si and amorphous carbon films deposited by direct carbon ion beams. Journal of Materials Research 14, 3221–3225 (1999). https://doi.org/10.1557/JMR.1999.0435

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1999.0435