Abstract

We described previously the liquid phase synthesis and characterization of a nanostructured composite from an aqueous solution containing organic polymer and inorganic ions [J. Mater. Res. 7, 2599 (1992)]. The nanocomposite, termed an organoceramic, consisted of poly(vinyl alcohol) chains intercalated between the principal layers of a hydrated calcium aluminate ceramic. A key structural feature of the organoceramic is the polymer-induced expansion of the interlayer spacing by approximately 10 Å compared to the unmodified ceramic. In this paper, we describe the synthetic scheme that favors organoceramic formation and prove the existence of intercalated polymer by observation of reversible interlayer expansion and contraction in response to changes in ambient humidity. This property is unique to the organoceramic and is not observed in the unmodified calcium aluminate ceramic.

Similar content being viewed by others

References

For a recent review, see E. P. Giannelis, Adv. Mater. 8, 29 (1996).

A. Blumstein, J. Polym. Sci., Part A 3, 2653 (1965).

C. Kato, K. Kuroda, and M. Misawa, Clays Clay Miner. 27, 129 (1979).

V. Mehrotra and E. P. Giannelis, Solid State Commun. 77, 155 (1991).

P. B. Messersmith and E. P. Giannelis, Chem. Mater. 5, 1064 (1993).

A. Usuki, Y. Kojima, M. Kawasumi, A. Okada, Y. Fukushima, T. Kurauchi, and O. Kamigaito, J. Mater. Res. 8, 1179 (1993).

P. B. Messersmith and E. P. Giannelis, Chem. Mater. 6, 1719 (1994).

M. S. Wang and T.J. Pinnavaia, Chem. Mater. 6, 468 (1994).

Z. Wang, T. Lan, and T. J. Pinnavaia, Chem. Mater. 8, 2200 (1996).

R. A. Vaia, H. Ishii, and E. P. Giannelis, Chem. Mater. 5, 1694 (1993).

S. I. Stupp and G. W. Ciegler, J. Biomed. Mater. Res. 26, 169–183 (1992).

P. B. Messersmith and S. I. Stupp, J. Mater. Res. 7, 2599 (1992).

P. B. Messersmith and S. I. Stupp, Chem. Mater. 7, 454 (1995).

P. B. Messersmith and S. I. Stupp, Polym. Prepr. 32, 536 (1991).

P. B. Messersmith and S. I. Stupp, in Advanced Cementitious Systems: Mechanisms and Properties, edited by F.P. Glasser, G. J. McCarthy, J. F. Young, T. O. Mason, and P. L. Pratt (Mater. Res. Soc. Symp. Proc. 245, Pittsburgh, PA, 1992), p. 191.

P. B. Messersmith, Ph.D. Thesis, University of Illinois (1993).

C. E. Becze and G. Xu, J. Mater. Res. 12, 566 (1997).

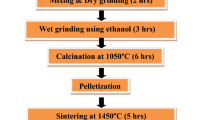

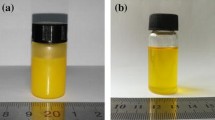

A saturated calcium hydroxide solution was prepared by stirring excess CaO (99.9%, Aldrich) in de-ionized water at 5 °C for 1 h and then filtering to remove undissolved material. PVA (99.7% hydrolyzed, \(\overline {{M_v}} = 61,000\), PolySciences) was dissolved in a small amount of de-ionized water and added to the filtered Ca(OH)2 solution. A second solution containing Ca2+ and Al3+ ions was prepared by stirring 5 g of monocalcium aluminate (CaAl2O4, 99.99%, Alfa Chemicals) in 500 ml de-ionized water for 90 min at room temperature and then removing undissolved solids by filtration. The PVA concentration was 100 mM with respect to the total precipitation volume. After cooling both solutions to 5 °C and purging with N2, 1 part of the Ca/Al solution was transferred via cannula into 5 parts of stirred Ca(OH)2/PVA solution. Precipitation began to occur within minutes after the start of transfer and was allowed to continue to completion (~24 h). Organoceramic was isolated from the reaction mixture by centrifuging and decanting the supernatant, followed by washing and de-ionized water and acetone prior to drying in vacuo. Dry powders were stored over CaSO4 at 5 °C.

R. Turriziani, in The Chemistry of Cements, edited by H. F. W. Taylor (Academic Press, New York, 1964), pp. 233–286.

Becze and Xu17 used both a different solids/water ratio as well as an extended mixing time (3–5 h) compared to our preparation of the supersaturated calcium aluminate solution.

Powders were stored in sealed containers above saturated aqueous salt solutions as follows: BaCl2 (90.0% RH); NaCl (75.3% RH); NaBr (57.6% RH); NaOH (8.2% RH); P2O5 (0% RH).

H.F.W. Taylor, Miner. Mag. 39, 377 (1973).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Messersmith, P.B., Osenar, P. & Stupp, S.I. Preparation of a nanostructured organoceramic and its reversible interlayer expansion. Journal of Materials Research 14, 315–318 (1999). https://doi.org/10.1557/JMR.1999.0044

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1999.0044