Abstract

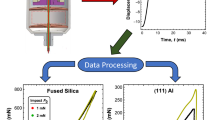

The information provided by the shape of the unloading portion of indentation curves is used to calculate the area of contact between the indenter and the material. Results obtained in fused silica and nickel, including Young’s modulus and hardness values, are presented to illustrate the validity of the approach. It is shown that errors of only a few percent are introduced when fitting unloading curves with power laws. The present method is especially useful when direct specimen stiffness measurements can be performed.

Similar content being viewed by others

References

J. L. Loubet, Courbes d’indentation et effet d’échelle quelques cas expérimentaux, Thesis, Lyon, France (1986).

M. F. Doerner and W. D. Nix, J. Mater. Res. 1, 601 (1986).

W. C. Oliver and G. M. Pharr, J. Mater. Res. 7, 1564 (1992).

A. Bolshakov, W. C. Oliver, and G. M. Pharr, in Thin Films: Stresses and Mechanical Properties V, edited by S. P. Baker, C. A. Ross, P. H. Townsent, C. A. Volkert, and P. Børgesen (Mater. Res. Soc. Symp. Proc. 356, Pittsburgh, PA, 1995), p. 675.

C. M. Segedin, Mathematika, 4, 156 (1957).

I. N. Sneddon, Int. J. Eng. Sci. 3, 47 (1965).

J. Woirgard and J-C. Dargenton, Meas. Sci. Technol. 6, 16–21 (1995).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Woirgard, J., Dargenton, JC. An alternative method for penetration depth determination in nanoindentation measurements. Journal of Materials Research 12, 2455–2458 (1997). https://doi.org/10.1557/JMR.1997.0324

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1997.0324