Abstract

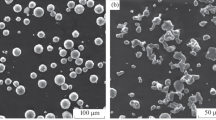

A high-purity, single-phase TiO2 ceramic with high density, strength, and electrical conduction was developed as a key structural material for the production equipment of semiconductors. Green bodies were made of high purity rutile TiO2 of very fine powder. They were sintered in air at 1200 °C for 2 h and then were hot isostatically pressed (HIPed) in argon at 1000°C, 150 MPa for 2 h. HIPed TiO2 ceramics were found to be electrically conductive and pore free. Their relative density, specific resistance, and bending strength were 100%, 1 Ω • cm, and 300 MPa, respectively. No strength degradation was found to the temperature up to 1000 °C. This material has high potential for use as electrically conductive structure materials in the semiconductor industry.

Similar content being viewed by others

References

G. A. Wardly, Rev. Sci. Instrum 44, 1506–1509 (1973).

T. Watanabe, T. Aoshima, T. Kitabayashi, and C. Nakayama, J. Ceram. Soc. Jpn. 101, 1107–1114 (1993).

A. J. Bosman and H. J. van Daal, Adv. Phys. 19, 1 (1970).

H. Gruber and E. Krautz, Z. Metallkd. 77, 203–206 (1986).

V. Wilms and H. Herman, Thin Solid Films 39, 251 (1976).

M. Kamal and S. E. Pratsing, J. Am. Ceram. Soc. 75, 3408–3416 (1992).

K. Kamata, K. Maruyama, and S. Amano, J. Mater. Sci. Lett. 9, 316–319 (1990).

M. Nanko, K. Isizaki, and T. Fujikawa, J. Am. Ceram. Soc. 77, 2437–2442 (1994).

N. M. Alford, K. Kendall, W. J. Clegg, and J. D. Birchall, Adv. Ceram. Mater. 3, 113–117 (1988).

A. Kishimoto, K. Koumoto, and H. Yanagida, J. Am. Ceram. Soc. 72, 1373–1376 (1989).

H. Wohlfromm, P. Pena, J. S. Moya, and J. Requena, European Ceramic Conference 1st Masstric, 1211–1217 (1989).

D. W. Roy and F. P. Rochester, U.S. Patent 3 459 503, Aug. 5 (1969).

R. L. Fullman, Trans. Am. Inst. Min., Metall., Pet. Eng. 3, 447–453 (1953).

K. Watari, Y. Seki, and K. Isizaki, J. Ceram. Soc. Jpn. 97, 56–62 (1989).

K. Uematsu, K. Itakura, M. Sekiguchi, N. Uchida, K. Saito, and A. Miyamoto, J. Am. Ceram. Soc. 72, 1239–1240 (1989).

K. Uematsu, K. Itakura, M. Sekiguchi, N. Uchida, K. Saito, A. Miyamoto, and T. Miyashita, . Am. Ceram. Soc. 73, 74–78 (1990).

J-Y. Kim, N. Uchida, and K. Uematsu, J. Ceram. Soc. Jpn. 100, 311–314 (1992).

D. Lewis III, Fracture Mechanics of Ceramics, edited by R. C. Bradt, A. G. Evans, D. P. H. Hasselman, and F. F. Lange (Plenum, New York, 1983), Vol. 6, pp. 487–496.

T. Sato, M. Ishitsuka, and M. Shimada, Materials & Design 9, 204–212 (1988).

P. Kofstad, Nonstoichiometry, Diffusion, and Electrical Conductivity in Binary Metal Oxides (John Wiley, New York, 1972) p. 141.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kishi, Y., Ogura, K., Kamata, K. et al. High strength, electrically conductive pore-free TiO2 ceramics made by hot isostatic pressing. Journal of Materials Research 12, 1056–1061 (1997). https://doi.org/10.1557/JMR.1997.0147

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1997.0147