Abstract

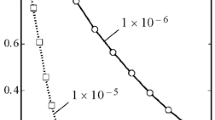

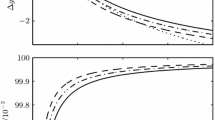

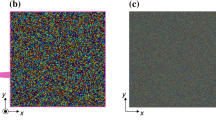

The effect of a second-phase particle size distribution on grain boundary pinning was studied using a Monte Carlo simulation technique. Simulations were run using a constant number density of both whisker and rhombohedral particles, and the effect of size distribution was studied by varying the standard deviation of the distribution around a constant mean particle size. The results of present simulations indicate that, in accordance with the stereological assumption of the topological pinning model, changes in distribution width had no effect on the pinned grain size. The effect of induced unpinning of particles on microstructure was also studied. In contrast to predictions of the topological pinning model, a power law dependence of pinned grain size on particle size was observed at T = 0.0. Based on this, a systematic deviation to the stereological predictions of the topological pinning model is observed. The results of simulations at higher temperatures indicate an increasing power law dependence of pinned grain size on particle size, with the slopes of the power law dependencies fitting an Arrhenius relation. The effect of induced unpinning of particles was also studied in order to obtain a correlation between particle/boundary concentration and equilibrium grain size. The results of simulations containing a constant number density of monosized rhombohedral particles suggest a strong power law correlation between the two parameters.

Similar content being viewed by others

References

C. Zener, as quoted by C. S. Smith, Trans. Metall. Soc. AIME 175, 15 (1948).

M. P. Anderson, G. S. Crest, R. D. Doherty, K. Li, and D. J. Srolovitz, Scripta Metall. 23, 753 (1989).

G. N. Hassold, E. A. Holm, and D. J. Srolovitz, Scripta Metall. Mater. 24, 101 (1990).

D. J. Srolovitz, M. P. Anderson, and G. S. Crest, Acta Metall. 32, 1429 (1984).

R. D. Doherty, K. Li, K. Kashyup, M. P. Anderson, and G. S. Grest, in Simulation and Theory of Evolving Microstructures, edited by M. P. Anderson and A. D. Rollett (TMS Publications, Warrendale, PA, 1989).

P. M. Hazzledine and R. D. J. Oldershaw, Philos. Mag. A 61, 579 (1989).

R. D. Doherty, D. J. Srolovitz, A. D. Rollett, and M. P. Anderson, Scripta Metall. 21, 675 (1987).

G. N. Hassold and E. A. Holm, Computers in Physics 7, 97 (1993).

E. A. Holm, G. N. Hassold, and D. J. Srolovitz, in Simulation and Theory of Evolving Microstructures, edited by M. P. Anderson and A. D. Rollett (TMS Publications, Warrendale, PA, 1989).

E. E. Underwood, Quantitative Stereology (Addison-Wesley Publishing Co., Reading, MA, 1970).

E. A. Holm, unpublished work.

L. C. Stearns, Ph. D. Thesis, Lehigh University, March 1995 (unpublished work).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Thompson, G.S., Rickman, J.M., Harmer, M.P. et al. The effects of particle size distribution and induced unpinning during grain growth. Journal of Materials Research 11, 1520–1527 (1996). https://doi.org/10.1557/JMR.1996.0190

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1996.0190