Abstract

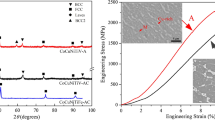

The microstructure and the high-temperature deformation behavior of the C15 NbCr2 intermetallics alloyed with V, which consist of both the C15 monophase and the duplex structure with the bcc solid solution, are observed by some microscopic techniques and compression tests. The alloys consisting of the C15 monophase microstructure show moderately higher 0.2% yield stress than the unalloyed NbCr2, and the same BDTT as that in the unalloyed NbCr2, indicating a moderate improvement of the high temperature deformability. This result is attributed to the larger atomic free volumes between the atomic stacking layers along the {111} planes than those of the unalloyed NbCr2. The alloys consisting of the duplex microstructure show lower 0.2% yield stress and considerably decreased BDTT than the unalloyed NbCr2. The considerable deformation improvement in this group of alloys is attributed to the existence of the ductile bcc solid solution.

Similar content being viewed by others

References

F. Laves, in Theory of Alloy Phase (ASM, Metals Park, OH, 1956), p. 123.

I. E. Gladyshevskii and O. Bodak, in Intermetallic Compounds, Vol. 1, Principles, edited by J. H. Westbrooke and R. L. Fleischer (John Wiley & Sons, Inc., New York, 1995), p. 403.

P. Villars and L. D. Calvert, in Pearson’s Handbook for Cristallographic Data for Intermetallic Phases (American Society for Metals, Metals Park, OH, 1985).

D. J. Thomas and J. H. Perepezko, Mater. Sci. Eng. A156, 97 (1992).

T. Takasugi, S. Hanada, and M. Yoshida, Mater. Sci. Eng. A192/193, 805 (1995).

M. Yoshida, T. Takasugi, and S. Hanada, in High-Temperature Ordered Intermetallic Alloys VI, edited by J. Horton, I. Baker, S. Hanada, R. D. Noebe, and D. Schwartz (Mater. Res. Soc. Symp. Proc. 364, Pittsburgh, PA, 1995), p. 1395.

M. Takeyama and C. T. Liu, Mater. Sci. Eng. A132, 61 (1991).

T. Takasugi, S. Hanada, and K. Miyamoto, J. Mater. Res. 8, 3069 (1993).

F. Chu and D. Pope, Mater. Sci. Eng. A170, 39 (1993).

F. Chu and D. Pope, in High-Temperature Ordered Intermetallic Alloys VI, edited by J. Horton, I. Baker, S. Hanada, R. D. Noebe, and D. Schwartz (Mater. Res. Soc. Symp. Proc. 364, Pittsburgh, PA, 1995), p. 1197.

T. B. Massalski, J. L. Murray, L. H. Bennett, and H. Baker, in Binary Alloy Phase Diagram (American Society for Metals, Metals Park, OH, 1986).

D. Shindo, M. Yoshida, T. Takasugi, and S. Hanada, unpublished.

D. M. Shah and D. L. Anton, in High-Temperature Ordered Intermetallic Alloys IV, edited by L. Johnson, D. P. Pope, and J. O. Stiegler (Mater. Res. Soc. Symp. Proc. 213, Pitsburgh, PA, 1991), p. 63.

J. D. Livingston and E. L. Hall, J. Mater. Res. 5, 5 (1990).

K. Inoue and T. Tachikawa, IEEE Trans. Magn. 13, 840 (1977).

K. Inoue, T. Kuroda, and T. Tachikawa, IEEE Trans. Magn. 15, 635 (1979).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Takasugi, T., Yoshida, M. & Hanada, S. Microstructure and high-temperature deformation of the C15 NbCr2-based Laves intermetallics in Nb–Cr–V alloy system. Journal of Materials Research 10, 2463–2470 (1995). https://doi.org/10.1557/JMR.1995.2463

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1995.2463