Abstract

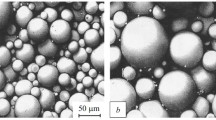

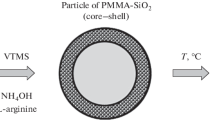

Hollow ceramic microspheres of Al2O3, SiO2, and mullite have been prepared by the combination of an emulsion technique with a water extraction sol-gel method. Concentration of sol, initial droplet size, and water extraction rate of the system are found to be the important process parameters controlling the size and wall thickness of the hollow microspheres, and their influences are shown. A model that correlates the morphology of microspheres to concentration and water extraction rate is proposed and is in good agreement with the experimental observations. The capability and limitation of this process for forming hollow microspheres are demonstrated. It was shown that hollow microspheres with sizes greater than 5 μm could be readily prepared, while a limitation was met for sizes less than 1 μm, in which case solid microspheres were normally formed.

Similar content being viewed by others

References

M. McMurrer, Plastics Compounding, November/December, 16 (1985).

C. D. Hendricks, in Glass Science and Technology, Vol. 2 (Academic Press, New York, 1984), p. 149.

R. L. Downs, M. A. Ebner, and W. J. Miller, Sol-Gel Technology for Thin Films, Fibers, Performs, Electronics, and Specialty Shapes, edited by L. C. Klein (Noyes Publications, Park Ridge, NJ, 1988), p. 330.

P. Siliva, L. E. Cross, T. R. Gururaj, and B. E. Scheetz, Mater. Lett. 4 (11,12), 475 (1986).

D. W. Kellerman, in Proceedings of the 37th Electronic Components Conference (IEEE, Boston, MA, 1987), p. 316.

D. J. Vernetti and D. L. Wilcox, in Proceedings of the 1992 International Symposium on Microelectronics (ISHM, San Francisco, CA, 1992), p. 117.

W. R. Beck and D. L. O’Brien, United States Patent 3 365 315 (1968), assigned to the 3M Company.

C. D. Hendricks, A. Rosencwaig, R. L. Woerner, J. C. Koo, J. L. Dressier, J. W. Sherohman, S. L. Weinland, and M. Jeffries, J. Nucl. Mater. 85/86, 107 (1979).

F. Veatch, H. E. Alford, and R. D. Croft, United States Patent 3 030215 (1962), assigned to the Standard Oil Company.

D. I. Netting, United States Patent 3 794503 (1974); United States Patent 3 796 777 (1974); United States Patent 3 888957 (1975), assigned to Philadelphia Quartz Company.

R. J. Walsh, United States Patent 3 161468 (1964), assigned to Monsanto Company.

K. K. Kim, K.Y. Jang, and R. S. Upadhye, J. Am. Ceram. Soc. 74 (8), 1987 (1991).

S. S. Jada, J. Mater. Sci. Lett. 9 (5), 565 (1990).

A. M. Gadalla and H-F. Yu, J. Mater. Res. 5, 2923 (1990).

Y. Sarikaya and M. Akinc, Ceram. Int. 14, 239 (1988).

H. G. Sowman, United States Patent 4 349456 (1982), assigned to the 3M Company.

D. J. Vernetti and D. L. Wilcox, in Proceedings of the 1992 International Conference on Multichip Modules (ISHM/IEPS, Denver, CO, 1992), p. 300.

G. L. Messing, S. Zhang, and G. V. Jayanthi, J. Am. Ceram. Soc. 76 (11), 2707 (1993).

S. Zhang and G. L. Messing, J. Am. Ceram. Soc. 73 (1), 61 (1990).

J. G. Liu and D. L. Wilcox, in Better Ceramics Through Chemistry VI edited by C. Sanchez, C. J. Blinker, M. L. Mecartney, and A. Cheetham (Mater. Res. Soc. Symp. Proc. 346, Pittsburgh, PA, 1994), p. 201.

D. H. Charlesworth and W. R. Marshall, Jr., AIChE J. 6 (1), 9 (1960).

G. V. Jayanthi, S. C. Zhang, and G. L. Messing, Aerosol Sci. Technol. 19, 478 (1993).

L. Kelly, A. T. Kleinsteuber, S. D. Clinton, and O. C Dean, Indus. & Eng. Chem.-Process Design & Development 4 (2), 212 (1965).

P. A. Haas, W. D. Bond, M. H. Lloyd, and J. P. McBride, in Thorium Fuel Cycle (Proc. 2nd Int. Thorium Fuel Cycle Symp., Gatlinburg, TN, 1966), p. 391.

R. G. Wymer, in Sol-Gel Processes for Ceramic Nuclear Fuels (Proc. Panel on Sol-Gel Processes for Ceramic Nuclear Fuels, Vienna, Austria, 1968), p. 131.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Liu, J.G., Wilcox, D.L. Factors influencing the formation of hollow ceramic microspheres by water extraction of colloidal droplets. Journal of Materials Research 10, 84–94 (1995). https://doi.org/10.1557/JMR.1995.0084

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1995.0084