Abstract

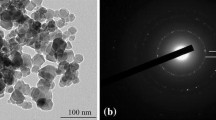

Monolithic CoSi and TiB2 reinforced CoSi materials were produced by spray atomization and co-deposition. The creep behavior of both materials at elevated temperature was investigated. The unreinforced material of grain size ≍25 μm exhibited a stress exponent of three, activation energy for creep of 320 kJ/mole, dislocation substructure of homogeneously distributed dislocations, and inverse creep transients upon stress increases. These results suggest that the creep behavior of CoSi is controlled by a dislocation glide mechanism. In contrast, the reinforced material of a finer grain size (≍10 μm) exhibited a stress exponent of unity, activation energy for creep of 240 kJ/mole, and negligible creep transients upon stress increases, suggesting that the creep behavior of the reinforced material is controlled by a diffusional creep mechanism. The creep resistance of the reinforced material was lower than that for the unreinforced material. This is a result of the finer grain size and higher porosity in the reinforced material.

Similar content being viewed by others

References

P. J. Meschter, Scripta Metall. Mater. 25, 1065 (1991).

J. M. Yang, W. Kai, and S. M. Jeng, Scripta Metall. Mater. 24, 1953 (1989).

C. H. Henager, Jr., J. L. Brimhall, and J. P. Hirth, Scripta Metall. 26, 585 (1992).

F. D. Gac and J. J. Petrovic, J. Am. Ceram. Soc. 68 (8), C-200 (1985).

R. M. Aiken, Jr., Ceram. Eng. Sci. Proc. 12 (9–10), 1643 (1991).

K. Sadananda, H. Jones, J. Feng, J. J. Petrovic, and A. K. Vasudévan, Ceram. Eng. Sci. Proc. 12 (9–10), 1671 (1991).

S. M. Wiederhorn, R. J. Gettings, D. E. Roberts, C. Ostertag, and J. J. Petrovic, Mater. Sci. Eng. A 155, 209 (1992).

K. Sadananda, C. R. Feng, H. Jones, and J. J. Petrovic, Mater. Sci. Eng. A 155, 227 (1992).

X. Liang, J. C. Earthman, E. J. Lavernia, Acta Metall. Mater. 40, 11 (1992).

B. P. Bewlay and B. Cantor, J. Mater. Res. 6, 1433 (1991).

R. Machler, P. J. Uggowitzet, C. Solenthaler, R. M. Pedrazzoli, and H. O. Speidel, Mater. Sci. Technol. 7, 447 (1991).

J. Baram, Metall. Trans. 22A, 2515 (1991).

M. Gupta, F. A. Mohamed, and E. J. Lavernia, Metall. Trans. 23A, 831 (1992).

S. Haviprasad, S. M. L. Sastry, K. L. Jernia, and R. J. Lederich, Metall. Trans. 24A, 865 (1993).

R. P. Singh, A. Lawley, S. Freidman, and Y. V. Murty, Mater. Sci. Eng. A 145, 243 (1991).

P. Lengsfeld and E. J. Lavernia, current research, University of California, Irvine.

E. J. Lavernia, E. Gutierrez, and J. Baram, Mater. Sci. Eng. A 132, 119 (1991).

E. J. Lavernia, E. Gomez, and N. J. Grant, Mater. Sci. Eng. 95, 251 (1987).

S. Annavarapu, D. Apelian, and A. Lawley, Metall. Trans. 19A, 3077 (1988).

I. Ucock, T. Ando, and N. J. Grant, Mater. Sci. Eng. A 145, 284 (1991).

Y. Ikawa, T. Itami, K. Kumagai, Y. Kawashima, A. G. Leatham, J. S. Coombs, and R. J. Brooks, J. Iron Steel Inst. Jpn. 30 (9), 756 (1990).

S. Annavarapu, D. Apelian, and A. Lawley, Metall. Trans. 21A, 3237 (1990).

A. L. Moran and W. A. Palko, J. Metals 40 (12), 12 (1988).

D. G. Morris and M. A. Morris, J. Mater. Res. 6, 361 (1991).

X. Liang, J. C. Earthman, and E. J. Lavernia, Mater. Sci. Eng. A 153, 646 (1992).

R. Vetter, L. Z. Zhuang, I. Majewska-Glabus, and J. Duszczyk, Scripta Metall. Mater. 24, 2025 (1990).

E. J. Lavernia, J. A. Ayers, and T. S. Srivatsan, Int. Mater. Rev. 37, 1 (1992).

M. Gupta, F. A. Mohamed, and E. J. Lavernia, Mater. Sci. Eng. A 144, 99 (1991).

M. Gupta, J. Juarez-Islas, W. E. Frazier, F. A. Mohamed, and E. J. Lavernia, Metall. Trans. 23B, 719 (1992).

E. J. Lavernia, Int. J. Rapid Solid. 5, 47 (1989).

J. Llorca, A. Martin, J. Ruiz, and M. Elices, Metall. Trans. 24A, 1575 (1993).

T. C. Willis, Metals Mater. 4 (8), 485 (1988).

A. R. E. Singer, Met. Powder Rep. 3, 223 (1986).

J. White, I. G. Palmer, I. R. Hughes, and S. A. Court, in Aluminum-Lithium Alloys, edited by E. A. Starke, Jr. (Materials and Component Engineering Publications, Birmingham, U. K., 1989), Vol. 5, p. 1635.

K. A. Kojima, R. E. Lewis, and M. J. Kaufman, in Aluminum-Lithium Alloys, edited by T. H. Sanders, Jr. and E. A. Starke, Jr. (Materials and Component Engineering Publications, Birmingham, U. K., 1989), Vol. 1, p. 85.

Y. Wu and E. J. Lavernia, Metall. Trans. 23A, 2923 (1992).

R. Perez, J. Zhang, M. Gungor, and E. J. Lavernia, Metall. Trans. 24A, 701 (1993).

G. Frommeyer, R. Rosenkranz, and C. Ludecke, Z. Metallk. 18, 307 (1991).

R. R. Vandervoort, A. K. Mukherjee, and J. E. Dorn, ASM 59, 930 (1966).

J. Wolfenstine, H. K. Kim, and J. C. Earthman, Scripta Metall. Mater. 26, 1823 (1992).

J. Wolfenstine, J. Mater. Sci. Lett. 9, 1091 (1990).

M. Rudy and G. Sauthoff, Mater. Sci. Eng. 81, 525 (1986).

D. L. Yaney and W. D. Nix, J. Mater. Sci. 23, 3088 (1986).

W. R. Cannon and O. D. Sherby, Metall. Trans. 1, 1030 (1970).

F. A. Mohamed and T. G. Langdon, Acta Metall. 22, 779 (1974).

M. Pahutova and J. Cadek, Phys. Status Solidi A 56, 305 (1979).

F. A. Mohamed, Mater. Sci. Eng. 61, 149 (1983).

S. H. Hong and J. Weertman, Acta Metall. 34, 743 (1986).

K. J. Hemker, M. J. Mills, and W. D. Nix, Acta Metall. Mater. 39, 1901 (1991).

J. Weertman, J. Appl. Phys. 28, 1185 (1957).

J. Weertman and J. R. Weertman, in Physical Metallurgy, edited by R. W. Chan (North-Holland, Amsterdam, The Netherlands, 1965), p. 1002.

A. K. Mukherjee and J. E. Dorn, J. Inst. Met. 93, 397 (1964–65).

P. A. Flinn, Trans. Metall. Soc. AIME 233, 714 (1960).

P. L. Martin, M. G. Mendiratta, and H. A. Lipsitt, Metall. Trans. 14A, 2876 (1983).

J. D. Whittenberger, J. Mater. Sci. 22, 394 (1987).

F. R. N. Nabarro, in Report From The Conference on The Strength of Solids (Physics Society, London, 1948), p. 75.

C. Herring, J. Appl. Phys. 21, 437 (1950).

R. L. Coble, J. Appl. Phys. 34, 1679 (1963).

S. V. Raj and T. G. Langdon, Acta Metall. 37, 843 (1989).

O. A. Ruano, A. K. Miller, and O. D. Sherby, Mater. Sci. Eng. 51, 9 (1981).

H. J. Frost and M. F. Ashby, Deformation Mechanism Maps (Pergamon Press, Oxford University, 1982).

A. K. Ghosh, A. Basu, and H. Kung, in Intermetallic Matrix Composites II, edited by D. B. Miracle, D. L. Anton, and J. A. Graves (Mater. Res. Soc. Symp. Proc. 273, Pittsburgh, PA, 1992), p. 259.

J. D. Whittenberger, R. S. Viswanadham, S. K. Mannan, and K. S. Kumar, J. Mater. Res. 4, 1164 (1989).

M. S. DiPietro, K. S. Kumar, and J. D. Whittenberger, J. Mater. Res. 6, 530 (1991).

K. S. Kumar, M. S. DiPietro, and J. D. Whittenberger, Acta Metall. Mater. 41, 1379 (1993).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Baskin, D., Wolfenstine, J. & Lavernia, E.J. Elevated temperature mechanical behavior of CoSi and particulate reinforced CoSi produced by spray atomization and co-deposition. Journal of Materials Research 9, 362–371 (1994). https://doi.org/10.1557/JMR.1994.0362

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1994.0362