Abstract

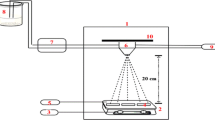

Polycrystalline CuInS2 thin films are prepared by sulfuration of Cu–In–O films. The Cu–In–O films are deposited from a sintered Cu2In2O5 target by using a pulsed laser deposition (PLD) method. Then, the Cu–In–O films are converted into CuInS2 films by means of a subsequent annealing in an H2S gas atmosphere. The characteristics of the films are determined by using an x-ray diffractometer (XRD), an energy dispersive x-ray spectrometer (EDX), and a scanning electron microscope (SEM). The effects of the deposition and sulfuration temperatures of the Cu–In–O films on the structural and microstructural properties of CuInS2 films are examined experimentally. Single-phase CuInS2 films with a chalcopyrite structure are obtained when Cu–In–O films are sulfurated at a temperature higher than 400 °C. Grain size of CuInS2 is larger when a lower deposition temperature and a higher sulfuration temperature of Cu–In–O films are employed.

Similar content being viewed by others

References

J. Shay and J. Wernick, Ternary Chalcopyrite Semiconductors: Growth, Electronic Properties, and Applications (Pergamon, New York, 1975).

A. Rockett and R.W. Birkmire, J. Appl. Phys. 70, R81 (1991).

L. Y. Sun, L. L. Kazmerski, A. H. Clark, P. J. Ireland, and D. W. Morton, J. Vac. Sci. Technol. 15, 265 (1978).

K. W. Mitchell, G. A. Pollock, and A. V. Mason, Proc. 20th IEEE Photovoltaic Spec. Conf., 1542 (1988).

H. J. Lewerenz, H. Goslowsky, K. D. Hasemann, and S. Fiechter, Nature 321, 687 (1986).

S. P. Grindle, C. W. Smith, and S. D. Mittleman, Appl. Phys. Lett. 35, 24 (1979).

J. J. M. Binsma and H. A. Van Der Linden, Thin Solid Films 97, 237 (1982).

A. Gupta and S. N. Murthy, J. Mater. Chem. 1, 929 (1991).

T. Wada, T. Negami, and M. Nishitani, submitted to Appl. Phys. Lett.

JCPDS Powder Diffraction File, Card No. 30-0479 (Joint Committee on Powder Diffraction Standards, Swarthmore, PA, 1984).

JCPDS Powder Diffraction File, Card No. 6-0416 (Joint Committee on Powder Diffraction Standards, Swarthmore, PA, 1984).

JCPDS Powder Diffraction File, Card No. 5-0661 (Joint Committee on Powder Diffraction Standards, Swarthmore, PA, 1984).

JCPDS Powder Diffraction File, Card No. 27-0159 (Joint Committee on Powder Diffraction Standards, Swarthmore, PA, 1984).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wada, T., Negami, T. & Nishitani, M. Microstructure of CuInS2 films prepared by sulfuration of Cu–In–O films. Journal of Materials Research 8, 545–550 (1993). https://doi.org/10.1557/JMR.1993.0545

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1993.0545