Abstract

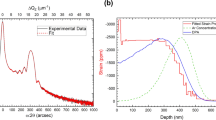

Implantation of Ta into single crystal Ni3Al was conducted to determine the degree of surface hardening in monolithic alloys in relation to its lattice location. Ta was implanted at 400 keV to doses of 0.07, 0.36, and 2.52 × 1016 cm−2 along the [100] axis of a [100] crystal of Ni3Al at room temperature. Composition versus depth profiles were determined by RBS, and lattice location of Ta was determined by channeling angular yield scans about the [100] axis. The hardness of the surface was measured by ultra-low load indentation. Results show that implantation softens the surface and that the Ta is randomly distributed between Ni and Al sites. Annealing at 1000 °C/1 h significantly reduces the damage and causes preferential occupation of Al sites by Ta, resulting in a slight increase in surface hardness. Further annealing at 1200 °C/0.25 h increases the surface hardness substantially and increases occupation of Al lattice sites to roughly 84%. Results are consistent with a model in which the as-implanted surface is softened by disordering, and subsequent diffusion of Ta to Al sites during thermal treatment causes hardening of the surface.

Similar content being viewed by others

References

L. R. Curwick, Ph.D. Dissertation, University of Minnesota, 1972.

F. Heredia and D. P. Pope, in High-Temperature Ordered Inter-metallic Alloys, II, edited by N.S. Stoloff, C.C. Koch, C.T. Liu, and O. Izumi (Mater. Res. Soc. Symp. Proc. 81, Pittsburgh, PA, 1987), pp. 213–220.

R.D. Rawlings and A. Staton-Bevan, J. Mater. Sci. 10, 505 (1975).

K. Aoki and O. Izumi, Phys. Status Solidi (a) 38, 587 (1976).

D.M. Wee and T. Suzuki, Trans. Jpn. Inst. Met. 20, 634 (1979).

D. V. Wee, O. Noguchi, Y. Oya, and T. Suzuki, Trans. Jpn. Inst. Met. 21, 237 (1980).

D. S. Pope and S. S. Ezz, Int. Metals Rev. 29, 136 (1984).

M.K. Miller and J. A. Horton, Scripta Metall. 20, 1125 (1986).

M.K. Miller and J.A. Horton, in High-Temperature Ordered Intermetallic Alloys, II, edited by N. S. Stoloff, C. C. Koch, C. T. Liu, and O. Izumi (Mater. Res. Soc. Symp. Proc. 81, Pittsburgh, PA, 1987), pp. 117–122.

J. Bentley, Proc. 44th Meeting of Electron Microscopy Society of America, Albuquerque, edited by G.W. Bailey (San Francisco Press, San Francisco, CA, 1986), p. 704.

M.K. Miller and J. Bentley, J. Phys. C7, 463 (1986).

H.G. Bohn, R. Schumacher, and R.J. Vianden, in High-Temperature Ordered Intermetallic Alloys, II, edited by N.S. Stoloff, C. C. Koch, C. T. Liu, and O. Izumi (Mater. Res. Soc. Symp. Proc. 81, Pittsburgh, PA, 1987), pp. 123–126.

H.G. Bohn, J.M. Williams, J.H. Barrett, and C.T. Liu, in High-Temperature Ordered Intermetallic Alloys, II, edited by N.S. Stoloff, C.C. Koch, C.T. Liu, and O. Izumi (Mater. Res. Soc. Symp. Proc. 81, Pittsburgh, PA, 1987), pp. 127–133.

H. Lin, L. E. Seiberling, P. F. Lyman, and D. P. Pope, in High-Temperature Ordered Intermetallic Alloys, II, edited by N. S. Stoloff, C.C. Koch, C.T. Liu, and 0. Izumi (Mater. Res. Soc. Symp. Proc. 81, Pittsburgh, PA, 1987), pp. 165–170.

J. H. Barrett, Nucl. Instrum. Methods B30, 546 (1988).

H. Lin and D.P. Pope, J. Mater. Res. 5, 763–768 (1990).

D. J. Morrison, J. W. Jones, G. S. Was, A. Mashayekhi, and J. W. Hoffman, in Thin Films: Stresses and Mechanical Properties, edited by J.C. Bravman, W.D. Nix, D.M. Barnett, and D.A. Smith (Mater. Res. Soc. Symp. Proc. 130, Pittsburgh, PA, 1989), pp. 53–58.

J. F. Ziegler, J. P. Biersack, and U. Littmark, The Stopping and Range of Ions in Solids (Pergamon Press, New York, 1984), p. 1.

J. W. Mayer and S.S. Lau, Electronic Materials Science: For Integrated Circuits in Si and GaAs (Macmillan Publishing Co., New York, 1990), pp. 231–232.

M. F. Doerner and W. D. Nix, J. Mater. Res. 1, 601 (1986).

G. S. Was, J. Mater. Res. 5, 1668 (1990).

L. R. Doolittle, Nucl. Instrum. Methods B9, 344 (1985).

M. Ahmed and D. I. Potter, Acta Metall. 35, 2341 (1987).

J. Eridon, G. S. Was, and L. Rehn, J. Mater. Res. 3, 626 (1988).

S. M. Foiles and M. S. Daw, J. Mater. Res. 2, 5 (1987).

L. C. Feldman, J. W. Mayer, and S. T. Picraux, Materials Analysis by Ion Channeling (Academic Press, New York, 1982).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Was, G.S., Mantl, S. & Oliver, W. Lattice location and hardness of Ta-implanted Ni3Al. Journal of Materials Research 6, 1200–1206 (1991). https://doi.org/10.1557/JMR.1991.1200

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1991.1200