Abstract

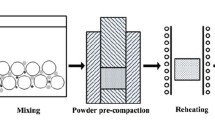

Cryomilling (high intensity mechanical ball milling in a liquid nitrogen bath) of the B2 crystal structure nickel aluminide leads to a NiAl composite containing about 10 vol.% of AlN particles. This is the result of a reaction milling process, where nitrogen incorporated into the matrix during cryomilling reacts with Al during subsequent thermomechanical processing to form the composite. Compressive testing at 1300 K of such materials densified by 1505 K extrusion or isostatic pressing at 1323 K or 1623 K indicated that strength at relatively fast strain rates (>10−7 s−1) is slightly dependent on the method of consolidation. At slower rates, however, no clear dependency on densification technique appears to exist, and four different consolidation methods possessed similar creep strengths. In all cases deformation at 1300 K occurred by two distinct mechanisms: at high strain rates the stress exponent is greater than 11 while at slower rates (<10−7 s−1) a much lower stress exponent (∼6) was found. Comparison of density compensated creep strengths reveals that the properties of NiAl–AlN are similar to those of the single crystal Ni-base superalloy NASAIR 100.

Similar content being viewed by others

References

J. D. Whittenberger, J. Mater. Sci. 22, 394 (1987).

J.D. Whittenberger, J. Mater. Sci. 23, 235 (1988).

R. S. Polvani, Wen-Shian Tzeng, and P. R. Strutt, Metall. Trans. A 7A, 33 (1976).

K. Vedula, V. Pathare, 1. Aslandis, and R. H. Titran, in High-Temperature Ordered Intermetallic Alloys, edited by C. C. Koch, C.T. Liu, and N. S. Stoloff (Mater. Res. Soc. Symp. Proc. 39, Pittsburgh, PA, 1985), pp. 411–421.

V. M. Pathare, Ph.D. Thesis entitled “Processing, Physical Metallurgy and Creep of NiA1 + Ta and NiA1 + Nb Alloys,” Case Western Reserve University, 1987 (also available as NASA CR-182113, 1988).

J. Daniel Whittenberger, R. K. Viswanadham, S. K. Mannan, and K.S. Kumar, J. Mater. Res. 4, 1164 (1989).

J. Daniel Whittenberger, M.V. Nathal, S.V. Raj, and V.M. Pathare, “Slow Strain Rate 1200–1400 K Compressive Properties of NiAl-1Hf” to be submitted to Mater. Lett.

J. Daniel Whittenberger, L. J. Westfall, and M.V. Nathal, Scripta Metall. 23, 2127 (1989).

S.C. Jha, R. Ray, and J. Daniel Whittenberger, Mater. Sci. Eng. A119, 103 (1989).

J. Daniel Whittenberger, R. K. Viswanadham, S. K. Mannan, and B. Sprissler, J. Mater. Sci. 35, 35 (1990).

J. Daniel Whittenberger, K. S. Kumar, and S. K. Mannan, “1200 and 1300 K slow plastic compression properties of Ni-50A1 composites,” accepted by High Temperature Technology.

R. D. Noebe, R. R. Bowman, and J. I. Eldridge, in Intermetallic Matrix Composites, edited by D. L. Anton, R. McMeeking, D. Miracle, and P. Martin (Mater. Res. Soc. Symp. Proc. 194, Pittsburgh, PA, 1990), pp. 323–332.

J. Daniel Whittenberger, Eduard Arzt, and Michael J. Luton, J. Mater. Res. 5, 271 (1990).

M. J. Luton, C. S. Jayanth, M. M. Disko, S. Matras, and J. Vallone, in Multicomponent Ultrafine Microstructures, edited by L. E. McCandish, B. H. Kear, D. E. Polk, and R.W. Siegel (Mater. Res. Soc. Symp. Proc. 132, Pittsburgh, PA, 1989), pp. 79–86.

G. Jangg, New Materials by Mechanical Alloying Techniques, edited by E. Arzt and L. Schultz (DGM Informationsgelschaft MBH, Oberursel, West Germany, 1989), pp. 39–52.

J. D. Whittenberger, B. C. Buzek, and G. Wirth, J. Mater. Sci. 21, 923 (1986).

J. D. Whittenberger, in Solid State Powder Processing, edited by A. H. Clauer and J. J. deBarbadillo (The Minerals, Metals and Materials Society, Warrendale, PA, 1990), pp. 137–155.

M. R. Harmouche and A. Wolfenden, Journal of Testing and Evaluation 15, 101 (1987).

J. D. Whittenberger, E. Arzt, and M. J. Luton, in Intermetallic Matrix Composites, edited by D. L. Anton, R. McMeeking, D. Miracle, and P. Martin (Mater. Res. Soc. Symp. Proc. 194, Pittsburgh, PA, 1990), pp. 211–217.

M.V. Nathal and L. J. Ebert, Metall. Trans. A 16A, 1863 (1985).

J.D. Whittenberger: NASA TP-1791, 1981.

Carl E. Lowell, Charles A. Barrett, and J. D. Whittenberger, in Intermetallic Matrix Composites, edited by D. L. Anton, R. McMeeking, D. Miracle, and P. Martin (Mater. Res. Soc. Symp. Proc. 194, Pittsburgh, PA, 1990), pp. 355–360.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Daniel Whittenberger, J., Arzt, E. & Luton, M.J. 1300 K compressive properties of a reaction milled NiAl–AlN composite. Journal of Materials Research 5, 2819–2827 (1990). https://doi.org/10.1557/JMR.1990.2819

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1990.2819