Abstract

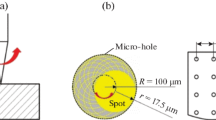

Single shot pulses from a Nd:YAG laser have been used to generate different sized holes and patterns in unfired ceramic sheets for electronic packaging applications. The single shot laser pulses were targeted using a computer controlled deflection system and a programmed pattern. With changes in pulse energy level and profile, the laser beam was also used to sinter line patterns in deposited thin and thick films. The surface radial temperature profile resulting from the laser pulse interaction was also directly mapped using a lacquer thermocoat. Effects of the laser pulse energy and beam spot size on laser/ceramic interactions, morphology, and structure of the drilled holes before and after sintering were examined by SEM. High quality hole patterns (of ∼100 μm hole size) were produced in unfired 100 μm thick ceramic sheets up to 100 μm thick using single shot of laser irradiation with 8 mJ pulse energy and 18 nsec pulse duration.

Similar content being viewed by others

References

S. M. Copley, M. Bass, B. Jan, and R. J. Wallace, in Laser Materials Processing, edited by M. Bass (North Holland, 1983), pp. 299–336.

T. R. Anthony, J. Appl. Phys. 53 (12), 9154–9164 (1982).

S. M. Copley, “Laser Machining—Ceramics,” in Int. Laser Processing Conf. Proc, Anaheim, CA, Nov. 16–17, 1981, Laser Institute of America, Title #20.

T. R. Anthony, J. Appl. Phys. 51 (2), 1170–1175 (1980).

S. L. Engel, Optical Engineering 17 (3), 235–237 (1978).

N. Rykalin, A. A. Uglov, and A. N. Kokora, in Laser Machining and Welding (Mir Publication, Moscow, 1978), pp. 126–200.

R. J. Wallace and S. M. Copley, Adv. Ceram. Mater. 1 (3), 227–283 (1986).

A. A. Uglov, A. N. Kokora, and N. V. Orekhov, Sov. J. Quant. Elect. 3 (6), 311–314 (1976).

W. W. Duley, in CO2 Laser: Effect and Application (Academic Press, New York, 1976), pp. 201–231.

R. E. Wagner, J. Appl. Phys. 45 (10), 4631–4637 (1974).

E. Kocher, L. Tschudi, J. Steffen, and G. Herziger, IEEE J. of Quant. Elect. QE-8 (2), 120–125 (1972).

John F. Ready, in Effects of High Power Laser Radiation (Academic Press, New York, 1971), pp. 359–409.

R. Jeanloz and D. L. Heinz, in Laser Welding, Machining and Material Processing (San Francisco, CA, ICEALO, Springer-Verlag, Berlin, 1985), pp. 239–243.

C. E. Yeack, R. L. Melcher, and H. E. Klauser, Appl. Phys. Lett. 41 (11), 1043–1044 (1982).

H. Jundt and J. Junghans, in Lasers in Motions for Industrial Applications, SPIE, 744, 147–155 (1986).

M. Oakes, Optical Engineering 17 (3), 217–224 (1978).

G. Herziger, in Industrial Application of High Power Lasers, edited by D. Schocker, SPIE, 455, 66–74 (1984).

R-F. Louh and R. C. Buchanan (Proc. Mater. Res. Soc. Symp.) (Materials Research Society, Pittsburgh, PA, 1988), Vol. 100, pp. 659–664.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Louh, RF., Buchanan, R.C. Hole pattern formation in unfired ceramic sheets by pulsed Nd:YAG laser. Journal of Materials Research 5, 841–846 (1990). https://doi.org/10.1557/JMR.1990.0841

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1990.0841