Abstract

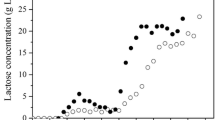

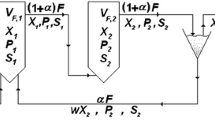

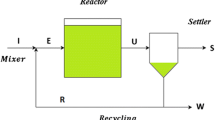

Immobilized cell utilization in tower-type bioreactor is one of the main alternatives being studied to improve the industrial bioprocess. Other alternatives for the production of β-lactam antibiotics, such as a cephalosporin C fed-batch process in an aerated stirred-tank bioreactor with free cells of Cephalosporium acremonium, or a tower-type bioreactor with immobilized cells of this fungus, have proven to be more efficient than the batch process. In the fed-batch process, it is possible to minimize the catabolite repression exerted by the rapidly utilization of carbon sources (such as glucose) in the synthesis of antibiotics by utilizing a suitable flow rate of supplementary medium. In this study, several runs for cephalosporin C production, each lasting 200 h, were conducted in a fed-batch tower-type bioreactor using different hydrolyzed sucrose concentrations. For this study's model, modifications were introduced to take intoaccount the influence of supplementary medium flow rate. The balance equations considered the effect of oxygen limitation inside the bioparticles. In the Monod-type rate equations, cell concentrations, substrate concentrations, and dissolved oxygen were included as reactants affecting the bioreaction rate. The set of differential equations was solved by the numerical method, and the values of the parameters were estimated by the classic nonlinear regression method following Marquardt's procedure with a 95% confidence interval. The simulation results showed that the proposed model fit well with the experimental data, and based on the experimental data and the mathematical model, an optimal mass flow rate to maximize the bioprocess productivity could be proposed.

Similar content being viewed by others

References

Ghosh, A. C., Bora, M. M., and Dutta, N. N. (1996), Bioseparation 6, 91–105.

Bayer, T., Zhou, W., Holzhauer, K., and Schügerl, K. (1989), Appl. Microbiol. Biotechnol. 30, 26–33.

König, B., Schügerl, K., and Seewald, C. (1982), Biotechnol. Bioeng. 24, 259–280.

Kundu, S., Mahapatra, A. C., Srivastava, P., and Kundu, K. (1992), Process Biochem. 27, 347–350.

Zanca, D. M., and Martín, J. F. (1983), J. Antibiot. 36(6), 700–708.

Matsumura, M., Imanaka, T., Yoshida, T., and Taguchi, H. (1981), J. Ferment. Technol. 59(2), 115–123.

Chu, W. Z., and Constantinides, A., (1988), Biotechnol. Bioeng. 32, 277–288.

Araujo, M. L. G. C., Oliveira, R. P., Giordano, R. C., and Hokka, C. O. (1996), Chem. Eng. Sci. 51(11), 2835–2840.

Araujo, M. L. G. C., Giordano, R. C., and Hokka, C. O. (1999), Biotechnol. Bioeng. 63 (5), 593–600.

Cruz, A. J. G., Silva, A. S., Araujo, M. L. G. C., Giordano, R. C., and Hokka, C. O. (1999), Chem. Eng. Sci. 54, 3137–3142.

Marquardt, D. W. (1963), J. Soc. Indust. Appl. Math. 2(2), 431–441.

Nihtilä, M., and Virkkunen, J. (1977), Biotechnol. Bioeng. 19(12), 1831–1850.

Zangirolami, T. C., Johansen, C. L., Nielsen, J., and Jorgensen, S. B. (1997), Biotechnol. Bioeng. 56(6), 593–604.

Demain, A. L., Newkirk, J. F., and Hendlin, D. (1963), J. Bacteriol. 85, 339–344.

Ribeiro, E. J. (1989), PhD thesis, FEA-UNICAMP, Campinas, SP, Brazil.

Almeida, R. M. R. G., Cruz, A. J. G., Araujo, M. L. G. C., Giordano, R. C., and Hokka, C. O. (1999), Proceedings of the XXVII Congresso Brasileiro de Sistemas Particulados, ENEMP-99, Campos do Jordão, SP, Brazil, in press.

Cruz, A. J. G., Araujo, M. L. G. C., Giordano, R. C., and Hokka, C. O. (1998), Appl. Biochem. Biotechnol. 70–72, 579–592.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Almeida, R.M.R.G., Cruz, A.J.G., Araujo, M.L.G.C. et al. Modeling and simulation of cephalosporin C production in a fed-batch tower-type bioreactor. Appl Biochem Biotechnol 91, 537–549 (2001). https://doi.org/10.1385/ABAB:91-93:1-9:537

Issue Date:

DOI: https://doi.org/10.1385/ABAB:91-93:1-9:537