Abstract

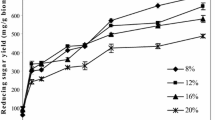

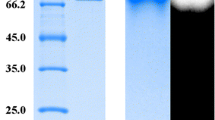

Kinetic conditions were established for the depolymerization of cassava starch for the production of maltodextrins and glucose syrups. Thin-layer chromatography and high-performance liquid chromatography analyses corroborated that the proper H3PO4 strengthand thermopressurization range (e.g., 142–170°C; 2.8–6.8 atm) can be successfully explored for such hydrolytic purposes of native starch granules. Because phosphoric acid can be advantageously maintained in the hydrolysate and generates, after controlled neutralization with ammonia, the strategic nutrient triplet for industrial fermentations (C, P, N), this pretreatment strategy can be easily recognized as a recommended technology for hydrolysis and upgrading of starch and other plant polysaccharides. Compared to the classic catalysts, the mandatory desalting step (chloride removal by expensive anion-exchange resin or sulfate precipitation as the calcium-insoluble salt) can be avoided. Furthermore, properly diluted phosphoric acid is well known as an allowable additive in several popular soft drinks such as colas since its acidic feeling in the mouth is compatible and synergistic with both natural and artificial sweeteners. Glycosyrups from phosphorolyzed cassava starch have also been upgraded to high-value single-cell protein such as the pigmented yeast biomass of Xanthophyllomyces dendrorhous (Phaffia rhodozyma), whose astaxanthin (diketo-dihydroxy-β-carotene) content may reach 0.5–1.0 mg/g of dry yeast cell. This can be used as an ideal complement for animal feeding as well as a natural staining for both fish farming (meat) and poultry (eggs).

Similar content being viewed by others

References

Krassig, H., Steadman, R. G., Schliefer, K., and Albrecht, W. (1986), Ullmann's Encyclopedia of Organic Compounds, 5th ed., A5, VCH.

Ramos, L. P. and Saddler, J. N. (1994), in Enzymatic Conversion of Biomass for Fuels Production, Himmel, M. E. Baker, J. D., and Overend, R. P., eds., American Chemical Society/ACS Symposium Series 566, Washington, DC, pp. 325–341.

Blanchard, P. H. and Katz, F. R. (1995), in Food Polysaccharides, Stephen, A. M., ed., Marcel Dekker, New York, pp. 99–122.

BeMiller, J. N. (1965), in Starch Chemistry and Technology vol. 1—Fundamental Aspects, Whistler, R. L. and Paschall, E. F., eds., Academic, New York, pp. 495–520.

Berk, Z. (1976), Braverman's Introduction to the Biochemistry of Foods, Elsevier SPC, Amsterdam, pp. 149–167.

Florencio, J. A., Raimbault, M., Guyot, J. P., Stofella, D. E. E., Soccol, C. R., and Fontana, J. D. (1999), Appl. Biochem. Biotechnol. 84/86, 1–13.

Fontana, J. D. (2000), in Food Microbiology Protocols, Spencer, J. F. T., Whelan, W. L., Brown, J., and Ragout de Spencer, A., eds., Humana, Totowa, NJ.

Fontana, J. D., Guimarāes, M. F., Martins, N. T., Fontana, C. A., and Baron, M. (1996), Appl. Biochem. Biotechnol. 57/58, 413–422.

Fontana, J. D., Correa, J. B. C., Duarte, J. H., Barbosa, A. M., and Blumel, M. (1984), Biotechnol. Bioeng. Symp. 14, 175–186.

Hauly, M. C. O., Bracht, A., Beck, R., and Fontana, J. D. (1992), Appl. Biochem. Biotechnol. 34/35, 292–308.

Author information

Authors and Affiliations

Corresponding author

Additional information

A patent request concerning this article's subject and its unfolding was addressed to Instituto Nacional da Propriedade Intelectual, Brazil, in May 2000 as protocol PI 0002001-0.

Rights and permissions

About this article

Cite this article

Fontana, J.D., Passos, M., Baron, M. et al. Cassava starch maltodextrinization/monomerization through thermopressurized aqueous phosphoric acid hydrolysis. Appl Biochem Biotechnol 91, 469–478 (2001). https://doi.org/10.1385/ABAB:91-93:1-9:469

Issue Date:

DOI: https://doi.org/10.1385/ABAB:91-93:1-9:469