Abstract

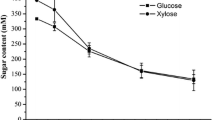

For optimum fermentation, fermenting xylose into acetic acid by Clostridium thermoaceticum (ATCC 49707) requires adaptation of the strain to xylose medium. Exposed to a mixture of glucose and xylose, it preferentially consumesxylose over glucose. The initial concentration of xylose in the medium affects the final concentration and the yield of acetic acid. Batch fermentation of 20 g/L of xylose with 5g/L of yeast extract as the nitrogen source results in a maximum acetate concentration of 15.2 g/L and yield of 0.76 g of acid/g of xylose. Corn steep liquor (CLS) is a good substitute for yeast extract and results in similar fermentation profiles. The organism consumes fructose, xylose, and glucose from a mixture of sugars in batch fermentation. Arabinose, mannose, and galactose are consumed only slightly. This organism loses viability on fed-batch operation, even with supplementation of all the required nutrients. In fed-batch fermentation with CSL supplementation, d-xylulose (an intermediate in the xylose metabolic pathway) accumulates in large quantities.

Similar content being viewed by others

References

Johnson, K. L. (1994), Cryotech Deicing Technologies, Fort Madison, IA.

Ljungdahl, L. G. (1983), Formation of Acetate Using Homoacetate Fermenting Anaerobic Bacteria in Organic Chemicals from Biomass, Menlo Park, CA.

Sugaya, K. and Jones, J. L. (1986), Biotechnol. Bioeng. 28, 678–683.

Wijitra, K. (1994), MS thesis, University of Illinois, Urbana.

Fontaine, F. E., Peterson, W. H., McCoy, E., and Johnson, M. J. (1942), J. Bacteriol. 43, 701–715.

Andreesen, J. R., Schaupp, A., Neurauter, C., Brown, A., and Ljundahl, L. G. (1973) J. Bacteriol. 114, 743–751.

Brumm, P. J. (1988), Biotechnol. Bioeng. 32, 444–450.

Parekh, S. R. and Cheryan, M. (1990), Process Biochem. Int. 25, 117–121.

Parekh, S. R. and Cheryan, M. (1990), Biotechnol. Lett. 16(2), 139–142.

Parekh, S. R. and Cheryan, M. (1990), Appl. Microbiol. Biotechnol. 36, 384–387.

Stephanopoulous, G. and San, K. Y. (1985), Biotechnol. Prog. 1(4), 250–259.

Liggett, R. W. and Koffler, H. (1948), Bacteriol. Rev. 12, 297–311.

Shah, M. M. and Cheryan, M. (1995), J. Ind. Microbiol. 15, 424–428.

Bock, S. A., Fox, S. L., and Gibbons, W. R. (1997), Biotechnol. Appl. Biochem. 25, 117–125.

Sikyta, B. (1983), Methods in Ind. Microbiol. Wiley, New York.

Larsson, S., Palmquist, E., and Nilvebrant, N., (1999), EnzymeMicrobiol. Technol. 24(3/4), 151–159.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balasubramanian, N., Seok Kim, J. & Lee, Y.Y. Fermentation of xylose into acetic acid by Clostridium thermoaceticum . Appl Biochem Biotechnol 91, 367–376 (2001). https://doi.org/10.1385/ABAB:91-93:1-9:367

Issue Date:

DOI: https://doi.org/10.1385/ABAB:91-93:1-9:367