Abstract

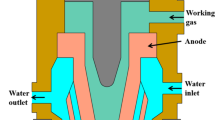

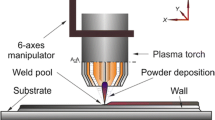

Plasma transferred arc (PTA) welded coatings are used to improve surface properties of mechanical parts. Advantages are the high reliability of the process and the low dilution of substrate and coating material. Processing of surfaces by PTA welding is restricted at the time to flat horizontal position. Furthermore, industry is interested in the development of strategies for coating with PTA in constraint position as complex three-dimensional (3D) parts could be then easily processed as well. Under commercial aspects, the process design can be optimized to increase process efficiency and to reduce heat input during the welding process. Process optimization involves the determination of guidelines for PTA welding in constraint positions as well. Modeling the process gives an alternative to reduce the experimental effort to optimize the welding process. Results of simulation studies of the PTA welding process are given in the present work. It will be shown that coating conditions can be optimized by varying plasma gas flow, heat input and heat flow, process speed, or powder injection with regard to welding in constraint positions. The defined controlling of the PTA welding allows modification of process management with less experimental effort and to develop coating strategies for processing in different positions. In experimental investigations, the developed coating strategies are confirmed by producing PTA coatings in constraint position as well as complex 3D parts.

Similar content being viewed by others

References

M. Akiyama, K. Tsubouchi, T. Okuyama, and N. Sakaguchi, Applications for Plasma Transferred Arc Welded Tools During Hot Steel Tube Making,Ironmaking Steelmaking, 2000,27(3), p 183–188

D. Harper, M. Gill, K.W.D. Hart, and M. Anderson, Plasma Transferred Arc Overlays Reduce Operating Costs in Oil Sand Processing,International Thermal Spray Conf. (Essen, Germany), March 4–6, 2002, ASM International, 2002, p 278–283

F. Schreiber, Mobile Plasma Powder Hand Deposition Welding: Practice Experience,International Thermal Spray Conf., March 4–6, 2002 (Essen, Germany), ASM International, 2002, p 273–277

B. Bouaifi, F. Schreiber, J. Göllner, and S. Schulze, Eigenschaften und Beständigkeit von Plasma-Pulver-Auftragschweißungen aus hartstoffverstärkten CrNiMoN-legierten Duplex-Stählen,DVS-Berichte, 1996,175, p 425–428, in German

S.M. Aithal, V.V. Subramanaiam, J. Pagan, R.W. Richardson, Numerical Model of a Transferred Plasma Arc,J. Appl. Phys., 1998,84(7), p 3506–3517

T. Amakawa, J. Jenista, J. Heberlein, and E. Pfender, Anode-Boundary Layer Behaviour in a Transferred, High-Intensity Arc,J. Physics D, Appl. Phys., 1998,31(20), p 2826–2834

H. Oertel Jr.,Prandtl-Führer durch die Strömungslehre, Vieweg & Sohn, Braunschweig/Wiesbaden, 2001, in German

Fluent 6.1 Users Guide. Fluent Inc., 2003

D’Ans, Lax, Taschenbuch für Chemiker und Physiker, Springer, 1998, in German

O. Kubaschewski,Materials Thermochemistry, Pergamon Press, 1993

J. Wilden, J.P. Bergmann, and M. Trommer, Einflussgrößen beim Plasma-Pulver-Auftragschweißen in Zwangslagen. In: Tagungsband zum 7,Werkstofftechnischen Kolloquium Neue Materialien und Verfahren in der Beschichtungstechnik (Hrsg.: Wielage, B.), 2004, p 214–219 (in German)

J. Wilden, J.P. Bergmann, and M. Trommer, Full Mechanised Cladding of 3-Dimensional Components in Constraint Position with the PPAW-Process,International Thermal Spray Conference, May 2–4, 2005 (Basel, Switzerland), DVS-Verlag, 2005

Author information

Authors and Affiliations

Corresponding author

Additional information

This article was originally published inBuilding on 100 Years of Success, Proceedings of the 2006 International Thermal Spray Conference (Seattle, WA), May 15–18, 2006, B.R. Marple, M.M. Hyland, Y.-Ch. Lau, R.S. Lima, and J. Voyer, Ed., ASM International, Materials Park, OH, 2006.

Rights and permissions

About this article

Cite this article

Wilden, J., Bergmann, J.P. & Frank, H. Plasma transferred arc welding—modeling and experimental optimization. J Therm Spray Tech 15, 779–784 (2006). https://doi.org/10.1361/105996306X146767

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996306X146767