Abstract

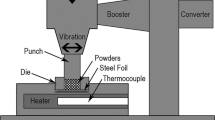

The authors have developed an in situ measurement system for precise one-to-one correlation between splat morphology and thermal history during particle impingement on a temperature-controlled substrate inside an airtight chamber under plasma-spraying conditions. The system has made it possible to collect about 10 single particles successively within a 10 s time frame, and to correlate exactly the relationship between the size, the temperature, and the impacting velocity of each droplet, and the morphology of the splats. The most striking finding is that a part of the yttria-stabilized zirconia (YSZ) droplets may be actually in supercooled condition before impinging, although a marked difference was not found in the splat morphology. In addition, as secondary results, we could evaluate the viscosity, μ, of YSZ, and the thermal contact resistance between YSZ splat and the quartz glass substrate as μ [Pa · s]=0.0037 exp (6110/T) and 3 × 10−6-4×10−5 m2 K/W, respectively.

Similar content being viewed by others

References

N.P. Padture, M. Gell, and E.H. Jordan, Thermal Barrier Coatings for Gas-Turbine Engine Applications, Science, Vol 296 (No. 5566), 2002, p 280–284

F. Gitzhofer, M. Boulos, J. Heberlein, R. Henne, T. Ishigaki, and T. Yoshida, Integrated Fabrication Processes for Solid-Oxide Fuel Cells Using Thermal Plasma Spray Technology, MRS Bull., Vol 25 (No. 7), 2000, p 38–42

T. Yoshida, Some Issues for the Development of Spraying Technology, Mater. Japan, Vol 40 (No. 4), 2001, p 322–325 (in Japanese)

J.R. Fincke, C.L. Jeffery, and S.B. Englert, In-Flight Measurement of Particle-Size and Temperature, J. Phys. E: Sci. Instrum., Vol 21 (No. 4), 1988, p 367–370

T. Sakuta and M.I. Boulos, Novel-Approach for Particle-Velocity and Size Measurement under Plasma Conditions, Rev. Sci. Instrum., Vol 59 (No. 2), 1988, p 285–291

J.R. Fincke, D.C. Haggard, and W.D. Swank, Particle Temperature Measurement in the Thermal Spray Process, J. Therm. Spray Technol., Vol 10 (No. 2), 2001, p 255–266

M. Vardelle, A. Vardelle, P. Fauchais, and C. Moreau, Pyrometer System for Monitoring the Particle Impact on a Substrate during a Plasma Spray Process, Meas. Sci. Technol., Vol 5 (No. 3), 1994, p 205–212

M. Vardelle, A. Vardelle, A.C. Leger, P. Fauchais, and D. Gobin, Influence of Particle Parameters at Impact on Splat Formation and Solidification in Plasma Spraying Processes, J. Therm. Spray Technol., Vol 4 (No. 1), 1995, p 50–58

P. Gougeon and C. Moreau, Simultaneous Independent Measurement of Splat Diameter and Cooling Time during Impact on a Substrate of Plasma-Sprayed Molybdenum Particles, J. Therm. Spray Technol., Vol 10 (No. 1), 2001, p 76–82

C. Moreau, P. Cielo, and M. Lamontagne, Flattening and Solidification of Thermally Sprayed Particles, J. Therm. Spray Technol., Vol 1 (No. 4), 1992, p 317–324.

G. Trapaga and J. Szekely, Mathematical-Modeling of the Isothermal Impingement of Liquid Droplets in Spraying Processes, Metall. Trans. B, Vol 22 (No. 6), 1991, p 901–914

M. Pasandideh-Fard, Y.M. Qiao, S. Chandra, and J. Mostaghimi, Capillary Effects during Droplet Impact on a Solid Surface, Phys. Fluids, Vol 8 (No. 3), 1996, p 650–659

M. Bussmann, S. Chandra, and J. Mostaghimi, Modeling the Splash of a Droplet Impacting a Solid Surface, Phys. Fluids, Vol 12 (No. 12), 2000, p 3121–3132

Y.K. Chae, J. Mostaghimi, and T. Yoshida, Deformation and Solidification Process of a Super-Cooled Droplet Impacting on the Substrate Under Plasma Spraying Conditions, Sci. Technol. Adv. Mater., Vol 1 (No. 3), 2000, p 147–156

J.P. Delplanque and R.H. Rangel, An Improved Model for Droplet Solidification on a Flat Surface, J. Mater. Sci., Vol 32 (No. 6), 1997, p 1519–1530

V.V. Sobolev, J.M. Guilemany, and A.J. Martin, Investigation of Droplet Flattening during Thermal Spraying, Surf. Coat. Technol., Vol 89, 1997, p 82–89

Y.P. Wan, H. Zhang, X.Y. Jiang, S. Sampath, and V. Prasad, Role of Solidification, Substrate Temperature and Reynolds Number on Droplet Spreading in Thermal Spray Deposition: Measurements and Modeling, Trans. ASME, Vol 123, 2001, p 382–389

H. Zhang, X.Y. Wang, L.L. Zheng, and X.Y. Jiang, Studies of Splat Molphology and Rapid Solidification during Thermal Spraying, Int. J. Heat Mass Transfer, Vol 44, 2001, p 4579–4592

C. Moreau, P. Cielo, M. Lamontagne, S. Dallaire, and M. Vardelle, Impacting Particle Temperature Monitoring during Plasma Spray Deposition, Meas. Sci. Technol., Vol 1 (No. 8), 1990, p 807–814

K. Shinoda, P. Han, and T. Yoshida, “The Microstructure of YSZ Splats Deposited by Hybrid Plasma Spraying,” Proceedings of the 15th International Symposium on Plasma Chemistry (Orleans, France), Vol 4, A. Bouchoule, et al., Ed., 2001, p 2661–2666

A. Savitzky and M.J.E. Golay, Smoothing and Differentiation of Data by Simplified Least Squares Procedures, Anal. Chem., Vol 36 (No. 8), 1964, p 1627–1639

M.W.J. Chase, Ed., NIST-JANAF Thermochemical Tables, 4th ed., Journal of Physical and Chemical Reference Data, Vol 9, American Chemical Society and American Institute of Physics for the National Institute of Standards and Technology, 1998

L.A. Dombrovsky and M.B. Ignatiev, An Estimate of the Temperature of Semitransparent Oxide Particles in Thermal Spraying, Heat Transfer Eng., Vol 24 (No. 2), 2003, p 60–68

S. Fantassi, M. Vardelle, A. Vardelle, and P. Fauchais, Influence of the Velocity of Plasma-Sprayed Particles on Splat Formation, J. Thermal Spray Technol., Vol 2 (No. 4), 1993, p 379–384

T. Yoshida, T. Okada, H. Hamatani, and H. Kumaoka, Integrated Fabrication Process for Solid Oxide Fuel Cells Using Novel Plasma Spraying, Plasma Sources Sci. Technol., Vol 1 (No. 3), 1992, p 195–201

P. Kozakevitch, Viscosite et elements structuraux des aluminosilicates fondus: laitiers CaO-Al2O3-SiO2 entre 1600 et 2100 C, Rev. Met., Vol 57, 1960, p 149–160 (in French)

R. Rossin, J. Bersan, and G. Urbain, Etude de la viscosite de laitiers liquides appartenant au systeme ternaire: SiO2-Al2O3-CaO, Rev. Hautes Temper. Refract., Vol 1, 1964, p 159–170 (in French)

V.P. Elyutin, V.I. Kostikov, B.S. Mitin, and Y.A. Nagibin, Measurement of Viscosity of Aluminum Oxide, Zh. Fiz. Khim., Vol 43, 1969, p 579–583 (in Russian)

J.L. Bates, C.E. McNeilly, and J.J. Rasmussen, Properties of Molten Ceramics, Ceramics in Severe Environments: Proceedings, Materials Science Research, W.W. Kriegel and H.I. Palmour, Ed., Plenum Press, 1971, p 11–26

R.A. Blomquist, J.K. Fink, and L. Leibowitz, Viscosity of Molten Alumina, Am. Ceram. Soc. Bull., Vol 57 (No. 5), 1978, p 522

G. Urbain, Viscosite de l’alumine liquide (Viscosity of Liquid Alumina), Rev. Int. Hautes Temp. Refract., Vol 19 (No. 1), 1982, p 55–57 (in French)

F. Sudreau and G. Cognet, Corium Viscosity Modelling Above Liquidus Temperature, Nucl. Eng. Des., Vol 178, 1997, p 269–277

A.V. Grosse, The Empirical Relationship between the Activation Energy Viscosity of Liquid Metals and Their Melting Points, J. Inorg. Nucl. Chem., Vol 255, p 317–318

M. Hirai, Estimation of Viscosities of Liquid Alloys, ISIJ Int., Vol 33 (No. 2), p 251–258

Author information

Authors and Affiliations

Additional information

The original version of this paper was published as part of the DVS Proceedings: “Thermal Spray Solutions: Advances in Technology and Application,” International Thermal Spray Conference, Osaka, Japan, 10–12 May 2004, CD-Rom, DVS-Verlag GmbH, Düsseldorf, Germany.

Rights and permissions

About this article

Cite this article

Shinoda, K., Kojima, Y. & Yoshida, T. In situ measurement system for deformation and solidification phenomena of yttria-stabilized zirconia droplets impinging on quartz glass substrate under plasma-spraying conditions. J Therm Spray Tech 14, 511–517 (2005). https://doi.org/10.1361/105996305X76531

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996305X76531