Abstract

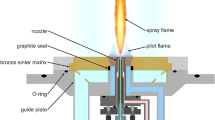

Aerosol flame spraying (AFS) combines the atomization of a colloidal suspension with the lateral injection of the aerosol in a flame. The aerosol droplets are partially dried when crossing the flame and then deposited as a coating onto a substrate. Afterwards, the coating is consolidated by heat treatment without extensive grain growth. In this paper a model of the trajectories, acceleration and vaporization of the droplets is used to predict the impact conditions of the in-flight dried droplets, as well as their size and water content when they impinge onto the substrate. From these calculations and the hydrodynamic properties (viscosity, surface tension, contact angle) of the suspensions, the morphology and size of the lamellae deposited on the substrate are determined by using classic impact models. In spite of the complexity of the mixing of the suspension spray with the flame and the diversity of the thermal histories of the droplets, the observation of the latter after impact shows that the results of the model are quite consistent with measurements. The relationship between droplet impact parameters and coating formation is discussed.

Similar content being viewed by others

References

J. Karthikeyan, C. Berndt, S. Reddy, J.-Y. Wang, A. King, and H. Herman: “Nanomaterial Deposits Formed by DC Plasma Spraying of Liquid Feedstocks,” J. Am. Ceram. Soc. 1998, 81(1), pp. 121–28.

A.R. Di Giampaolo, H. Reveron, H. Ruiz, T. Poirier, J. Lira, and H. Vesteghem: “Zirconia Coatings on Stainless Steel by Aerosol Thermal Spraying,” A.T.M, 1998, 1(1), pp. 90–100.

T. Poirier: “Zirconia Coatings Manufactured by Aerosol Flame Spraying,” Ph.D. Thesis, Université de Limoges. France, Nb: 49-2000 (in French).

H. Vesteghem, A. Lecomte, and A. Dauger: “Film Formation and Sintering of Colloidal Monoclinic Zirconia,” J. Non. Cryst. Solids, 1992, 147, 148, pp. 503–507.

H. Reveron: “Synthesis of Cerium-Partially Stabilized Zirconia,” Ph.D. Thesis, Université de Limoges, France, Nb: 51-2000 (in French).

J. Bernardin, C. Stebbins, and I. Mudawar: “Mapping of Impact and Heat Transfer Regimes of Water Drops Impinging on a Polished Surface,” Int. J. Heat Mass Transfer, 1997, 40(2), pp. 247–67.

M. Ciofalo, I. Di Piazza, and V. Brucato: “Investigation of the Cooling of Hot Walls by Liquid Water Sprays,” Int. J. Heat Mass Transfer, 1999, 42, pp. 1157–75.

Z. Liu and R. Reitz: “Modeling Fuel Spray Impingement and Heat Transfer Between Spray and Wall in Direct Injection Diesel Engines,” Numerical Heat Transfer, Part A, 1995, 28, pp. 515–29.

W.J. Yang: “Natural Convection in Evaporating Droplets” in Handbook of Heat and Mass Transfer, Vol. I, Heat Transfer Operations, N.P Cheremesinoff, ed., Golf Publishing Co., Houston, 1986, pp. 211–28.

J. Fukai, Y. Shiiba, and O. Miyatake: “Theoretical Study of Droplet Impingement on a Solid Surface Below the Leidenfrost Temperature,” Int. J. Heat Mass Transfer, 1997, 40(10), pp. 2490–92.

V. Sobolev: “Formation of Splat Morphology During Thermal Spraying,” Materials Letters, 1998, 36, pp. 123–127

M. Pasandideh-Fard, J. Mostaghimi, and S. Chandra: “3D Model of Droplet Impact and Solidification: Impact on a Solidified Splat” in Proceedings of the 14th International Symposium on Plasma Chemistry, M. Hrabovský, M. Konrád, and V. Kopecký, ed., Institute of Plasma Physics, Prague, 1999, pp. 2081–87.

A.C. Léger: “Experimental Study of Splat Formation and Residual Stresses in Plasma-Sprayed Coatings,” Ph.D. Thesis, Université de Limoges, France, Nb: 4-1997 (in French).

J.J. Bikerman, Physical Surfaces, Academic Press, London, United Kingdom, 1970, pp. 16–19.

K. Masters: Spray Drying, 2nd ed., J. Wiley, New York, 1976, pp. 206–84.

H. Ruiz: Technical Report, Surface and Interface Engineering Group, Universidad Simon Bolivar, Caracas, Venezuela, 1995.

P. Arques: Inflammation, Combustion, Pollution, Masson, Paris, France, 1992, pp. 6–11.

A. Vardelle: “Modeling of the Heat, Mass and Momentum Transfers Between DC Plasma Jets and Particles,” D.Sc. State Thesis, University of Limoges, France, Nb 27–87, 1987.

S. Schiaffino and A. Sonin: “Molten Droplet Deposition and Solidification at Low Weber Numbers,” Phys. Fluids, 1997, 9, pp. 3172–87.

J. Madejski: “Solidification of Droplets on a Cold Surface,” Int. J. Heat Mass Transfer, 1976, 19, pp. 1009–1013.

L. Bianchi: “DC and RF Plasma Spraying of Ceramic Coatings: Mechanisms of Formation of the First Layer and Relationship With the Mechanical Properties of the Coating,” Ph.D. Thesis, Université de Limoges, Nb: 41-1995 (in French).

C. Mundo, M. Sommerfeld, and C. Tropea: “Droplet-Wall Collisions: Experimental Studies of the Deformation and Break-up Process,” Int. J. Multiphase Flow, 1995, 21(2), pp. 151–73.

J. Senda, M. Kobayashi, S. Iwashita, and H. Fujimoto: “Modeling of Diesel Spray Impinging on Flat Wall,” JSME Int. J., Series B., 1996, 39(4), pp. 859–86.

J. Bernardin and I. Mudawar: “Film Boiling Heat Transfer of Droplet Streams and Sprays,” Int. J. Heat Mass Transfer, 1997, 40(11), pp. 2579–93.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Poirier, T., Vardelle, A., Elchinger, M.F. et al. Deposition of nanoparticle suspensions by aerosol flame spraying: Model of the spray and impact processes. J Therm Spray Tech 12, 393–402 (2003). https://doi.org/10.1361/105996303770348267

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996303770348267