Abstract

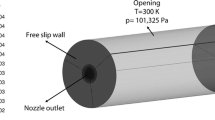

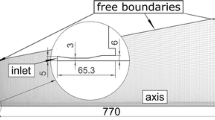

The behavior of metal and ceramic powders co-sprayed through a plasma jet was simulated using a commercial fluid dynamics model in which the particles are considered as discrete Langrangian entities. Computations were carried out for the plasma jet and the injected particles using (a) a steady-state three-dimensional (3-D) jet and (b) a simplified two-dimensional (2-D) model. An analytical method was used to estimate the appropriate injection velocities for the metal and ceramic particles, injected through opposing nozzles perpendicular to the plasma flow, so that their “mean” trajectories would impinge on the same area on the target surface. Comparison of the model projections with experimental measurements showed that this method of computation can be used to predict and control the behavior of particles of widely different properties.

Similar content being viewed by others

References

W. Smith, T.J. Jewett, S. Sampath, C C. Berndt, H. Herman, J. Fincke, and R.N. Wright: Thermal Spray: Practical Solutions for Engineering Problems, C. C. Berndt, ed., ASM International, Materials Park, OH, 1996, pp. 317–24.

M. Leylavergne, A. Vardelle, B. Dussoubs, and N. Goubot: J. Thermal Spray Technol., 1998, vol. 7 (4), pp. 527–36.

J.D. Mattei and O. Simonin: Logiciel ESTET, Manuel Théorique de la Version 3.1, EDF Report HE 44/92.38B, 1992 (in French).

B.E. Launder and B.I. Sharma: Lett. Heat Mass Transfer, 1974, vol. 1, pp. 131–38.

M.I. Boulos, P. Fauchais, and E. Pfender: Thermal Plasmas, Fundamental and Applications, Plenum Press, New York, NY, 1995, vol. 1.

C.H. Chang and J.D. Ramshaw: Plasma Chem. Plasma Processing, 1993, vol. 13 (2), pp. 189–209.

B. Dussoubs: Ph.D. Thesis, University of Limoges, Limoges, France, 1998, 23–1998.

J. Pozorski and J.P. Minier: Lagrangian Modeling of Turbulent Flows, EDF Report HE 44/94.106, 1994.

M. Vardelle, A. Vardelle, P. Fauchais, and M.I. Boulos: AIChE J., 1983, vol. 29 (2), 1983, pp. 236–43.

E. Pfender and Y.C. Lee: Plasma Chem. Plasma Processing, 1985, vol. 5 (3), pp. 211–37.

Y.C. Lee, Y.P. Chyou, and E. Pfender: Plasma Chem. Plasma Processing, 1985, vol. 5 (4), pp. 391–409.

G.T. Csanady: J. Atm. Sci., 1963, vol. 20, pp. 201–08.

A. Papoulis: Probability, Random Variables and Stochastic Processes, McGraw-Hill, New York, NY, 1965.

S.B. Pope: Progr. Energy Combust. Sci., 1985, vol. 11, pp. 119–92.

T. Yoshida: Ph.D. Thesis, University of Tokyo, Tokyo, 1976.

M. Vardelle, A. Vardelle, P. Fauchais, B. Dussoubs, T.J. Roemer, R.A. Neiser, and M.F. Smith: Thermal Spray: Meeting the Challenges of the 21st Century, C. Coddet, ed., ASM International, Materials Park, OH, 1998, pp. 887–94.

B. Dussoubs, A. Vardelle, M. Vardelle, P. Fauchais, and N.J. Themelis: Proc. 13th Int. Symp. on Plasma Chemistry, Beijing, Aug. 18–22, 1997, C. K. Wu, ed., Beijing University Press, Beijing, 1997, pp. 2056–61.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Dussoubs, B., Vardelle, A., Mariaux, G. et al. Modeling of plasma spraying of two powders. J Therm Spray Tech 10, 105–110 (2001). https://doi.org/10.1361/105996301770349565

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996301770349565