Abstract

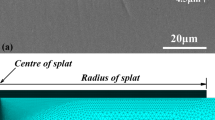

In thermal spray processes, the coating structure is the result of flattening and cooling of molten droplets on the substrate. The study of the cooling time and evolution of the splat size during impact is then of the highest importance to understand the influence of the spray parameters and substrate characteristics on the coating structure. Measurement of particle temperature during impact requires the use of a high-speed two-color pyrometer to collect the thermal emission of the particle during flattening. Simultaneous measurement of the splat size with this pyrometer is difficult since the size of the particle can change as it cools down. To measure the splat size independently, a new measurement technique has been developed. In this technique, the splat size is measured from the attenuation of the radiation of a laser beam illuminating the particle during impact. Results are presented for plasma-sprayed molybdenum particles impacting on a glass substrate at room temperature. It is shown that the molybdenum splat reaches its maximum extent about 2 µs after the impact. In this work, we show that this increase of the splat surface is followed by a phase during which the splat size decreases significantly during 2 to 3 µs.

Similar content being viewed by others

References

J. Madejski: Int. J. Heat Mass Transfer, 1976, vol. 19, pp. 1009–13.

J. Madejski: Int. J. Heat Mass Transfer, 1983, vol. 26 (7), pp. 1095–98.

G. Trapaga, E. F. Matthys, J. J. Valencia, and J. Szekely: Metall. Trans. B, 1992, vol. 23B, pp. 701–18.

T. Watanabe, I. Kuribayashi, T. Honda, and A. Kanzawa: Chem. Eng. Sci., 1992, vol. 47 (12), pp. 3059–65.

M. Bertagnolli, M. Marchese, and G. Jacucci: J. Thermal Spray Technol., 1995, vol. 4 (1), pp. 41–49.

H. Liu, E. J. Lavernia, and R. H. Rangel: J. Phys. D: Appl. Phys., 1993, vol. 26, pp. 1900–08.

A. C. Léger, M. Vardelle, A. Vardelle, P. Fauchais, S. Sampath, C. C. Berndt, and H. Herman: in Thermal Spray: Practical Solutions for Engineering Problems, C.C. Berndt, ed., ASM International, Materials Park, OH, 1996, pp. 623–28.

M. Pasandideh-Fard and J. Mostaghimi: in Thermal Spray: Practical Solutions for Engineering Problems, C. C. Berndt, ed., ASM International, Materials Park, OH, 1996, pp. 637–46.

H. Fukanuma: in Thermal Spray: Practical Solutions for Engineering Problems, C. C. Berndt, ed., ASM International, Materials Park, OH, 1996, pp. 647–56.

A. C. Léger, M. Vardelle, A. Vardelle, B. Dussoubs, and P. Fauchais: in Thermal Spray Science and Technology, C. C. Berndt and S. Sampath, eds., ASM International, Materials Park, OH, 1995, pp. 169–74.

M. Vardelle, A. Vardelle, A. C. Léger, and P. Fauchais: in Thermal Spray Industrial Applications, C. C. Berndt and S. Sampath, eds., ASM International, Materials Park, OH, 1994, pp. 555–62.

C. Moreau, P. Cielo, and M. Lamontagne: J. Thermal Spray Technol., 1992, vol. 1 (4), pp. 317–23.

C. Moreau, P. Gougeon, and M. Lamontagne: J. Thermal Spray Technol., 1995, vol. 4 (4), pp. 25–33.

L. Bianchi, F. Blein, P. Lucchese, M. Vardelle, A. Vardelle, and P. Fauchais: in Thermal Spray Industrial Applications, C. C. Berndt and S. Sampath, eds., ASM International, Materials Park, OH, 1994, pp. 569–74.

M. Fukomoto, S. Katoh, and I. Okane: in Thermal Spraying—Current Status and Future Trends, Akira Ohmori, ed., High Temperature Society of Japan, Osaka, 1995, pp. 353–58.

Y. Huang, M. Ohwatari, and M. Fukomoto: in The Role of Welding Science and Technology in the 21st Century, M. Ushio, ed., Japan Welding Society, Nagoya, 1996, pp. 731–36.

C. Moreau, P. Cielo, M. Lamontagne, S. Dallaire, and M. Vardelle: Meas. Sci. Technol., 1990, vol. 1, pp. 807–14.

M. Vardelle, A. Vardelle, P. Fauchais, and C. Moreau: Meas. Sci. Technol., 1994, vol. 5, pp. 205–12.

C. Moreau, P. Gougeon, and M. Lamontagne: in Thermal Spraying—Current Status and Future Trends, Akira Ohmori, ed., High Temperature Society of Japan, Osaka, 1995, pp. 347–51.

P. Gougeon, C. Moreau, V. Lacasse, M. Lamontagne, I. Powell, and A. Bewsher: in Advanced Processing Techniques—Particulate Materials, Metal Powder Industries Federation, Princeton, NJ, 1994, vol. 6, pp. 199–210.

C. Moreau, P. Gougeon, M. Lamontagne, V. Lacasse, G. Vaudreuil, and P. Cielo: in Thermal Spray Industrial Applications, C. C. Berndt and S. Sampath, eds., ASM International, Materials Park, OH, 1994, pp. 431–37

P. Gougeon and C. Moreau: J. Thermal Spray Technol., 1993, vol. 2 (3), pp. 229–33.

Metals Handbook, 8th ed., vol. 1, Properties and Selection of Metals, T. Lyman, ed., ASM, Metals Park, OH, 1961, p. 1216.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gougeon, P., Moreau, C. Simultaneous independent measurement of splat diameter and cooling time during impact on a substrate of plasma-sprayed molybdenum particles. J Therm Spray Tech 10, 76–82 (2001). https://doi.org/10.1361/105996301770349538

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996301770349538