Abstract

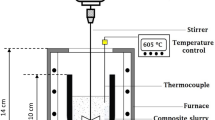

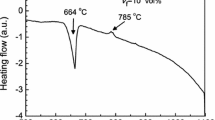

In situ particulate-reinforced Al and Al-Mg matrix composites were successfully fabricated by an oxygen spray technique. The results indicate that Al2O3 and MgAl2O4 particles directly nucleate and grow via gas-liquid oxidation reaction. The Al2O3 particles with the size of 0.1 to 0.5 µm are formed into the Al melt, according to an appropriate system and processing parameters. The reinforcements show a good wettability with the matrix. The hot-rolling process results in an improvement of the uniformity of the particle distribution in the matrix and an increase in the hardness of the composites.

Similar content being viewed by others

References

M.J. Koczak and M.K. Premkumar, JOM, January 1993, p 44

P. Sahoo and M.J. Koczak, Mater. Sci. Eng., Vol A144, 1991, p 37

E. Taheri-Nassaj, M. Kobashi, and T. Choh, Scr. Mater., Vol 34 (No. 8), 1996, p 1257

M. Kobashi and T. Choh, Third International SAMPE Metals Conf., 1992, p 20

Braszcynski, Janusz, Szumera, and Stanislaw, Z. Metallkd., Vol 80 (No. 6), 1989

T. Zhong and Y. Ji, BCEIA ’95, Vol A, 1995, p 109

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ji, Y., Gao, X. & Zhong, T. Formation and microstructure of an in situ aluminum composite by oxygen spray technique. J. of Materi Eng and Perform 8, 168–170 (1999). https://doi.org/10.1361/105994999770347007

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105994999770347007