Abstract

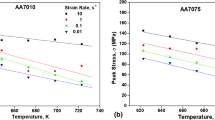

The deformation behavior of a 4032 aluminum alloy by hot compression has been investigated. It was found that the flow stress was strongly dependent on temperature as well as strain rate. The strain rate-sensitive coefficients were calculated at different temperatures. The experimental stress-strain data are fitted by means of the model earlier advanced by Sah et al. The Sellars-Tegart-Garofalo (STG) model is used to obtain activation energy values, which vary with the strain rate and strain.

Similar content being viewed by others

References

N. Erik, Modelling of Work Hardening and Stress Saturation in FCC Metals,Prog. Mater. Sci., 1997,41, p 129–193

Y. Estrin and H. Mecking, A Unified Phenomenological Description of Work-Hardening and Creep Based on One-Parameter Models,Acta Metall., 1984,32, p 57–70

F. Barlat, M.V. Glazov, J.C. Brem, and D.J. Lege, Simple Model for Dislocation Behavior, Strain and Strain Rate Hardening Evolution in Deforming Aluminum Alloys,Int. J. Plast., 2002,18, p 919–939

S. Spigarelli, E. Evangelista, and H.J. McQueen, Study of Hot Workability of a Heat Treated AA 6082 Aluminum Alloy,Scripta Mater., 2003,49, p 179–183

H.J. McQueen, X. Xia, Y. Cui, B. Li, and B. Meng, Solution and Precipitation Effects on Hot Workability of 6201 Alloy,Mater. Sci. Eng., A, 2001,319–321, p 420–424

B. Verlinden, A. Suhadi, and L. Delaey, A Generalized Constitutive Equation for an aa6060 Aluminum Alloy,Scripta Metall. Mater., 1993,28, p 1441–1446

J.P. Sah, G. Richardson, and C.M. Sellars, Recrysallization During Hot Deformation of Nickel,J.Aust. Inst. Metall., 1969,14, p 292–297

J. van de Langkruis, W.H. Kool, and S. van der Zwaag, Assessment of Constitutive Equations in Modeling the Hot Deformability of Some Overaged Al-Mg-Si Alloys with Varying Solute Contents,Mater. Sci. Eng., A, 1999,266, p 135–145

P. Cavaliere, Hot and Warm Forming of 2618 Aluminum Alloy,J. Light Metals, 2002,2, p 247–252

H.J. McQueen, E. Fry, and J. Belling, Comparative Constitutive Constants for Hot Working of Al-4.4Mg-0.7Mn (AA5083),J. Mater. Eng. Perform., 2001,10, p 164–172

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fang, G., Zeng, P. Investigation of thermal formability of aluminum alloy 4032. J. of Materi Eng and Perform 15, 535–539 (2006). https://doi.org/10.1361/105994906X136043

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105994906X136043