Abstract

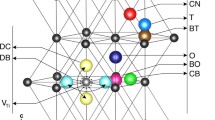

Thermodynamic modeling tools have become essential in understanding the effect of alloy chemistry on the final microstructure of a material. Implementation of such tools to improve titanium processing via parameter optimization has resulted in significant cost savings through the elimination of shop/laboratory trials and tests. In this study, a thermodynamic modeling tool developed at CompuTherm, LLC, is being used to predict β transus, phase proportions, phase chemistries, partitioning coefficients, and phase boundaries of multicomponent titanium alloys. This modeling tool includesPandat, software for multicomponent phase equilibrium calculations, andPanTitanium, a thermodynamic database for titanium alloys. Model predictions are compared with experimental results for one α-β alloy (Ti-64) and two near-β alloys (Ti-17 and Ti-10-2-3). The alloying elements, especially the interstitial elements O, N, H, and C, have been shown to have a significant effect on the β transus temperature, and are discussed in more detail herein.

Similar content being viewed by others

References

J.J. van Laar, Melting-Point and Freezing-Point Curves in Binary Systems, When the Solid Phase Is a Mixture of Both Components,Z. Phys. Chem., Vol 63, 1908, p 216

L. Kaufman,Computer Calculation of Phase Diagrams, Academic Press, 1970

I. Ansara, Comparison of Methods for Thermodynamic Calculation of Phase Diagrams,Int. Metals Rev., Vol 24 (No. 1), 1979, p 20–53

Y.-M. Muggianu, M. Gambino, and J.P. Bros, Enthalpies of Formation of Liquid Alloys Bismuth-Gallium-Tin at 723 K, Choice of an Analytical Representation of Integral and Partial Excess Functions of Mixing,J. Chim. Phys., Vol 72 (No. 1), 1975, p 83–88

B. Sundman and J. Agren, A Regular Solution Model for Phases with Several Components and Sublattices, Suitable for Computer Applications,J. Phys. Chem. Solids, Vol 42, 1981, p 297–301

W.A. Oates and H. Wenzl, The Bond Energy Model for Ordering in a Phase with Sites of Different Coordination Numbers,CALPHAD, Vol 16 (No. 1), 1992, p 73–78

S.-L. Chen, C.R. Kao, and Y.A. Chang, Generalized Quasi-Chemical Model for Intermetallic Compounds with Anti-Structure Defects,Intermetallics, Vol 3 (No. 3), 1995, p 233

U.R. Kattner, The Thermodynamic Modeling of Multicomponent Phase Equilibria,JOM (TMS), Vol 49 (No. 12), 1997, p 14–19

H. Liang and Y.A. Chang, A Thermodynamic Database on Aluminum Alloys for Practical Alloy Design,Light Metals, 1999, p 875–881

F.-Y. Xie,PanTitanium User Manual, Version 1, CompuTherm, LLC, Madison, WI, 2004

S.-L. Chen, F. Zhang, S. Daniel, F.-Y. Xie, X.-Y. Yan, Y.A. Chang, R. Schmid-Fetzer, and W.A. Oates, Calculating Phase Diagrams UsingPANDAT andPanEngine, JOM (TMS), Vol 55 (No. 12), 2003, p 48–51

V. Venkatesh, private communication, TIMET R&D, Henderson, NV, 2004

D. Furrer, private communication, Ladish Co., Inc., Cudahy, WI, 2004

T.W. Duerig, G.T. Terlinde, and J.C. Williams, Phase Transformations and Tensile Properties of Ti-10V-2Fe-3Al,Metall. Trans, Vol 11A (No. 12), 1980, p 1987–1998

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhang, F., Xie, F.Y., Chen, S.L. et al. Predictions of titanium alloy properties using thermodynamic modeling tools. J. of Materi Eng and Perform 14, 717–721 (2005). https://doi.org/10.1361/105994905X75501

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994905X75501