Abstract

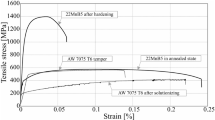

Research in the weight of an automobile is a continuous process among auto manufacturers. The “body in white” (BIW, i.e., the body of the car) deserves attention, being a major contributor to the weight of the vehicle. By virtue of a high strength to weight ratio (density smaller than aluminum) and a higher Young’s modulus than aluminum, aluminum-lithium alloy sheet appears to hold promise as an autobody material. Because auto components are required in large numbers and are formed at room temperature, formability under these conditions becomes significant. Aluminum-lithium alloys acquire, because of aging over a short period of time, a good amount of strength and hence dent resistance. In principle, they can be given, through suitable heat treatments, a high formability as well as dent resistance, i.e., an ideal combination of properties. To this end, tensile properties have been determined for a number of heat treatments comprising three different solutionizing temperatures and for three aging times at each of the three aging temperatures. Considerable influence of heat treatment was observed on the mechanical properties (which in turn characterize both formability and dent resistance), such as the strain hardening exponent, average normal anisotropy, yield stress, ultimate tensile stress, and percentage elongation to failure. For each property, the best three heat treatments leading to a high formability were identified. Consequently, heat treatments that imparted the greatest formability for processes such as deep drawing and stretch forming have been identified. The investigations show that the best heat treatment for one property may not be the best for another property, calling for a compromise to obtain the most practicable heat treatment schedule. Results shed light on not only the biaxial formability but also springback behavior that is important in the BIW components. Further, the properties obtained from the heat treatment giving good formability in deep drawing were used to simulate car body fender and the S-rail using sheet metal forming simulation software PAMSTAMP2G. A comparison of simulation of aluminum-lithium alloy fender and S-rail with those made from steel demonstrates advantages using aluminum-lithium alloys in terms of weight reduction. Finally, based on the current oil prices and the projected demand for oil in the next decade, aluminum-lithium alloys seem to have an edge despite the difficulties in manufacturing, assembly, and joining of the aluminum-lithium components.

Similar content being viewed by others

References

K. Fukuo, A. Fujimura, M. Saito, K. Tsunoda, and S. Takiguchi. Development of the Ultra-Low-Fuel-Consumption Hybrid Car: INSIGHT, JSAE Rev., Vol 22, 2001, p 95–103

D. Carle and G. Blount, The Suitability of Aluminum as an Alternative Material for Car Bodies, Mater. Design, Vol 20, 1999, p 267–272

D.V. Wilson, Aluminum Versus Steel in the Family Car on the Formability Factor, J. Mechan. Working Technol., Vol 16, 1988, p 257–277

R. Shinnar, The Effect of the Energy Crisis on the Private Car in the U.S., Transport. Res., Vol 9, 1975, p 87–95

D.L. Greene and K.G. Duleep, Costs and Benefits of Automotive Fuel Economy Improvement: A Partial Analysis, Transport. Res., Vol 27a (No. 3), 1993, p 217–235

R.H. Essinhigh, Evaluation of Fuel Consumption Rates and Thermal Efficiency of Automobiles by Application of Furnace Analysis, Transport. Res., Vol 8, 1974, p 457–464

M. Saito, S. Iwatsuki, K. Yasunaga, and K. Andoh, Development of Aluminum Body for the Most Fuel-Efficient Vehicle, JSAE Rev., Vol 21, 2000, p 511–516

E. Romhanji, D. Mitlin, and V. Radmilovic, Deformation Pattern and Strain Hardening in a Highly Textured 8090 Al-Li Alloy Sheet, J. Mater. Sci. Eng., Vol A291, 2000, p 160–167

R.K. Bird, D.L. Dicus, J.N. Fridlyander, and V.S. Sandler, Al-Li Alloy 1441 for Fuselage Application, Seventh International Conference on Aluminum Alloys (The Light Metals Centre at the University of Virginia, Charlottsville, Virginia), 2000, p 907–912

P.J.E. Bischler and J.W. Martin, Effect of Heat Treatment upon Tensile Strength and Fracture Properties of an Al-Li-Cu-Mg Alloy, Proceedings of the Third International Aluminum-Lithium Conference (Institute of Metals University of Oxford), 1985, p 220–233

P.S. Gilman, J.W. Brooks, and P.J. Bridges, High Temperature Tensile Properties of Mechanically Alloyed Al-Mg-Li Alloys, Proceedings of the Third International Aluminum-Lithium Conference (Institute of Metals University of Oxford), 1985, p 112–120

S.J. Harris, B. Noble, and K. Dinsdale, Effect of Composition and Heat Treatment on Strength and Fracture Characteristics of Al-Li-Mg Alloys, Proceedings of the Second International Aluminum-Lithium Conference (Metallurgical Society of AIME, Monteray, California), 1983, p 539–546

R.J. Kar, J.W. Bohlen, and G.R. Chennai, Correlation of Microstructures, Aging Treatments, and Properties of Al-Li-Cu-Mg-Zr I/M and P/M Alloys, Proceedings of the Second International Aluminum-Lithium Conference (Metallurgical Society of AIME, Monteray, California), 1983, p 255–285

J. White, W.S. Miller, I.G. Palmer, R. Davis, and T.S. Saini, Effect of Precipitation on Mechanical Properties of Al-Li-Cu-Mg-Zr Alloy, Proceedings of the Third International Aluminum-Lithium Conference (Institute of Metals University of Oxford), 1985, p 530–538

M.L. Bairwa and P.P. Date, Effect of Heat Treatments on Tensile Properties of Al-Li Alloys, Proceedings of International Conference AMPT2003 (Dublin City University, Dublin), 2003, p 115–118

http://www.eaa.net/downloads/Alumax%20A%20%20Final%20report.pdf

http://economictimes.indiatimes.com/articleshow/msid-754330,prtpagel.cms

http://www.lme.co.uk/dataprices_monthlyvolumes.asp

R.J. Pallett and R.J. Lark, The Use of Tailored Blanks in the Manufacture of Construction Components, J. Mater. Processing Technol., Vol 117, (No. 1–2), 2001, p 249–254

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bairwa, M.L., Desai, S.G. & Date, P.P. Identification of heat treatments for better formability in an aluminum-lithium alloy sheet. J. of Materi Eng and Perform 14, 623–633 (2005). https://doi.org/10.1361/105994905X64503

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994905X64503