Abstract

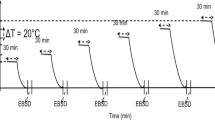

Commercially pure nickel has been processed via low-strain and high-strain routes using various thermomechanical cycles with isochronal annealing from 500 to 900 °C. Electron backscattered diffraction was used to characterize the percentage of special boundaries (Σ3–29) formed. Measurements also included twin variants based on Σ3n. Of the various single-strain and multiple-strain temperature combinations that were processed, both routes showed that a single low strain of about 2 to 6% followed by annealing at 900 °C for 10 min resulted in a doubling of the special fraction of grain boundaries. In addition, the Σ3n variants were also approximately doubled without the recourse to multiple processing and/or multiple heat treatments. It was proposed, based on theories from the literature, that extrinsic grain boundary dislocations formed at low strain levels in a mantle-core formation and, on annealing, climbed along the boundary and formed special grain boundary types.

Similar content being viewed by others

References

C.B. Thomas and V. Randle, Fine Tuning at Σ3n Boundaries in Nickel, Acta Mater., Vol. 45 (No. 12), 1997, p 4909–4916

A.J. Schwartz, M. Kumar, and W.E. King, Influence of Processing Method on the Grain Boundary Character Distribution and Network Connectivity, Mat. Res. Soc. Symp. Proc., Vol 586, 2000, p 3–13

G. Palumbo, Metal Alloys Having Improved Resistance to Intergranular Stress Corrosion Cracks, U.S. Patent 5,817,193, Oct 6, 1998

W.E. King and A.M. Schwartz, Towards Optimization of the Grain Boundary Character Distribution in OFE Copper, Scr. Mater., Vol 38 (No. 3), 1998, p 449–455

S.-L. Lee, “The Effects of Small Strains and Heat Treatment Processing on the Formation of Special Grain Boundaries in Commercially Pure Nickel,” Master’s thesis, University of Manitoba, 2003

B. Guyot, “Effect of Cold Working and Isochronal Annealing Processing Parameters on Special Grain Boundary Fractions in Commercial Purity Nickel,” Master’s thesis, University of Manitoba, 2003

B. Alexandereanu and G.S. Was, A Priori Determination of the Sampling Size for Grain-Boundary Character Distribution and Grain-Boundary Degradation Analysis, Philos. Mag. A, Vol 81 (No. 8), 2001, p 1951–1965

V. Randle, Grain Assemblage in Polycrystals, Acta Mater., Vol 42 (No. 6), 1994, p 1769–1784

M. Kumar, W.E. King, and A.J. Schwartz, Modifications to the Microstructural Topology in FCC Materials Through Thermomechanical Processing, Acta Mater., Vol 48 (No. 9), 2000, p 2081–2091

G.N. Hassold, E.A. Holm, and M.A. Miodownik, Accumulation of Coincidence Lattice Site Boundaries During Grain Growth, Mater. Sci. Technol., Vol 19 (No. 6), 2003, p 683–687

A.W. Thompson, M.J. Baskes, and W.F. Flanagan, The Dependence of Polycrystal Work Hardening on Grain Size, Acta Metall., Vol 21, 1973, p 1017–1028

J.C.M. Li, Petch Relationship and Grain Boundary Sources, Trans. AIME, Vol 227, 1963, p 239–247

L.E. Murr, Some Observations of Grain Boundary Ledges and Ledges as Dislocation Sources in Metals and Alloys, Metall. Trans., Vol 6A, 1975, p 505–513

M.A. Meyers and E. Ashworth, A Model for the Effect of Grain Size on the Yield Stress of Metals, Philos. Mag. A, Vol 46 (No. 5), 1982, p 737–759

S. Sangal and K. Tangri, Effect of Small Plastic Deformation and Annealing on the Properties of Polycrystals: Part II. Theoretical Model for the Transformation on Non-Equilibrium Grain Boundaries, Metall. Trans., Vol 20A (No. 3), 1989, p 479–489

H. Guo, M.S. Chaturvedi, and N.L. Richards, Effect of the Nature of Grain Boundaries on Intergranular Liquation During Welding of a Nickel Base Alloy, Sci. Technol. Weld., Vol 3 (No. 5), 1998, p 257–259

S. Mahajan, C.S. Pande, M.A. Imam, and B.B. Rath, Formation of Annealing Twins in fcc Crystals, Acta Mater., Vol 45 (No. 6), 1997, p 2633–2638

C.S. Pande, M.A. Imam, and B.B. Rath, Study of Annealing Twins in FCC Metals and Alloys, Metall. Mater. Trans., Vol 21A, 1990, p 2891–2896

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Guyot, B., Lee, S.L. & Richards, N.L. Effect of small strain levels on special boundary distribution in commercially pure nickel. J. of Materi Eng and Perform 14, 85–90 (2005). https://doi.org/10.1361/10599490522356

Received:

Issue Date:

DOI: https://doi.org/10.1361/10599490522356