Abstract

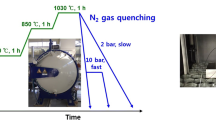

Distortion as a result of the quenching process is predominantly due to the thermal gradient and phase transformations within the component. Compared with traditional liquid quenching, the thermal boundary conditions during gas quenching are relatively simple to control. By adjusting the gas-quenching furnace pressure, the flow speed, or the spray nozzle configuration, the heat-transfer coefficients can be designed in terms of both the component geometry and the quenching time. The purpose of this research is to apply the optimization methodology to design the gas-quenching process. The design objective is to minimize the distortion caused by quenching. Constraints on the average surface hardness, and its distribution and residual stress are imposed. The heat-transfer coefficients are used as design variables. DEFORM-HT is used to predict material response during quenching. The response surface method is used to obtain the analytical models of the objective function and constraints in terms of the design variables. Once the response surfaces of the objective and constraints are obtained, they are used to search for the optimum heat-transfer coefficients. This process is then used instead of the finite-element analysis. A one-gear blank case study is used to demonstrate the optimization scheme.

Similar content being viewed by others

References

H. Altena, P. Stola, P. Jurci, F. Klima, and J. Paulu, Influence of Gas and Oil Quenching Parameters on Changes in Shape and Dimension of Gear Wheels, Heat Treat. Met., Vol 1, 2001, p 1–8

K. Funatani, New Quenchants and Cooling Technology, Current Status and Future, Third Int. Conf. Quenching and Control of Distortion (Prague, the Czech Republic), ASM International, March 1999, p 5–16

S.J. Midea, T. Holm, S. Segerberg, J. Bodin, T. Thors, and K. Swärtstorm, High Pressure Gas Quenching: Technical and Economical Considerations, Second Int. Conf. Quenching and the Control of Distortion (Cleveland, OH), ASM International, Nov 1996, p 157–163

P. Heilmann, and W.R. Zenker, Gas Quenching Tool Steels, Adv. Mater. Proc., Vol 2, 1993, p 29–31

G.C. Carter, Optimization Gas Quenching, Adv. Mater. Proc., Vol 149 (No. 2), 1996, p 79–82

F.T. Hoffmann, T. Lübben, and P. Mayr, New Development in Quenching Systems and Equipment: Current Status and Future Developments, Third Int. Conf. Quenching and Control of Distortion (Prague, the Czech Republic), ASM International, March 1999, p 459–465

T.C. Tszeng, W.T. Wu, and J.P. Tang, Prediction of Distortion During Heat Treating and Machining Processes, Proc. 16th ASM Heat Treating Society Conference and Exposition (Cincinnati, OH), ASM International, 1996, p 9–15

T. Inoue and K. Arimoto, Development and Implementation of CAE System “HEARTS” for Heat Treatment Simulation Based on Metallo-Thermo-Mechanics, J. Mater. Eng. Perf., Vol 6 (No. 1), 1997, p 51–60

B.L. Ferguson, A. Freborg, and G. Petrus, Software Simulates Quenching, Adv. Mater. Proc., Vol 158 (No. 2), 2000, p 31–34

Y. Ruan, Inverse Optimal Design of Cooling Conditions for Continuous Quenching Processes, Int. J. Numer. Methods Eng., Vol 51, 2001, p 127–142

P.J. Röhl and S.K. Srivatsa, “A Comprehensive Approach to Engine IPPD,” AIAA report 97-1113, AIAA, 1997, p 1250–1257

G. Box and K. Wilson, On the Experimental Attainment of Optimum Condition, J.R. Stat. Soc., Vol 13, 1951, p 1–45

Z. Li, G. Ramana, and R. Shivpuri, Optimum Design of Heat Transfer Coefficient During Gas Quenching Process by Using Response Surface Method, J. Machine Tools Manufact., Vol 42, 2002, p 549–558

Z. Li, G. Ramana, and R. Srinivasan, Distortion Minimization During Gas Quenching Process, J. Mater. Proc. Technol. (in press)

B.H. Morales, J.K. Brimacombe, E.B. Hawbolt, and S.M. Gupta, Determination of Quench Heat-Transfer Coefficients Using Inverse Techniques, First Int. Conf. Quenching and Control of Distortion (Chicago, IL), ASM International, Sept 1992, p 155–164

S.G. Chen, C.I. Weng, and J. Lin, Inverse Estimation of Transient Temperature Distribution in the End Quenching Test, J. Mater. Proc. Technol., Vol 86, 1999, p 257–263

W.A. Johnson and F.R. Mehl, Reaction Kinetics in Processes of Nucleation and Growth, Trans. AIME, Vol 135, 1939, p 416–425

C.L. Magee, “Phase Transformations,” paper presented at Seminar of the American Society for Metals, ASM, 1968, p 115–154

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Li, Z., Grandhi, R.V. Multidisciplinary optimization of gas-quenching process. J. of Materi Eng and Perform 14, 136–143 (2005). https://doi.org/10.1361/10599490522257

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/10599490522257