Abstract

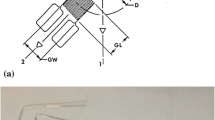

When precipitation-hardenable aluminum parts are water quenched, distortion occurs due to thermal stresses. Thereby, a costly reworking is necessary, and for this reason polymer quenchants are often used to reduce distortion, with the disadvantage that the quenched parts have to be cleaned after quenching. In opposition to liquid quenchants, gas quenching may decrease distortion due to the better temperature uniformity during quenching. Furthermore, cleaning of the quenched parts can be avoided because it is a dry process. For this purpose, a heat-treating process was evaluated that included a high-pressure gasquenching step. Gas quenching was applied to different aluminum alloys (i.e., 2024, 6013, 7075, and A357.0), and tensile tests have been carried out to determine the mechanical properties after solution annealing, gas quenching, and aging. Besides high-pressure gas quenching, alloy 2024 was quenched at ambient pressure in a gas nozzle field. The high velocity at the gas outlet leads to an accelerated cooling of the aluminum alloy in this case. Aluminum castings and forgings can be classified as an interesting field of application of these quenching methods due to their near-net shape before the heat treatment. Cost savings would be possible due to the reduced distortion, and therefore, less reworking after the precipitation hardening.

Similar content being viewed by others

References

G.E. Totten, G.M. Webster, and C.E. Bates, An Overview of Aluminum Quenching With Polymer Quenchants, Ind. Heat., Vol 65 (No. 11), 1974, p 61–66

C. Ikei, E. Hollis, A. Furman, D. Clark, J. Chavez, P. Huk, R. Tilak, E.W. Lee, and O.S. Es-Said, The Effect of Processing Parameters on the Mechanical Properties and Distortion Behavior of 6061 and 7075 Aluminum Alloy Extrusions, Mater. Sci. Forum, Vol 331–337, 2000, p 663–668

F.T. Hoffmann, T. Lübben, and P. Mayr, Innovations in Quenching Systems and Equipment: Current Status and Future Developments, Heat Treat. Met., Vol 26 (No. 3), 1999, p 63–67

J. Wünning, Single-Part Quenching of Serial Parts with Gas Jets Located in a Mold, Einzelteilhärtung von Serienbauteilen in Gasdüsenformen, Härt.-Tech. Mitt., Vol 48 (No. 3), 1993, p 199–204

J.W. Evancho and J.T. Staley, Kinetics of Precipitation in Aluminum Alloys During Continuous Cooling, Metall. Trans., Vol 5, 1974, p 43–47

Heat Treating, Vol 4, 9th ed., Metals Handbook, American Society for Metals, 1981, p 690–691

C.E. Bates, Selecting Quenchants to Maximize Tensile Properties and Minimize Distortion in Aluminum Parts, J. Heat Treat., Vol 5 (No. 1), 1987, p 27–40

C. Kammer, Aluminum-Taschenbuch Band I, Aluminum-Verlag Düsseldorf, 1998, Vol 1 p 250 (in German)

J.R. Davis, Ed., ASM Specialty Handbook: Aluminum and Aluminum Alloys, American Society for Metals, 1981, p 71–73

B. Edenhofer, An Overview of Advances in Atmosphere and Vacuum Heat Treatment, Heat Treat. Met., Vol 26 (No. 1), 1999, p 1–5

Mechanical Properties-6013-T6 Sheet, SPD-10-009, Alloy 6013 Sheet, ALCOA, www.millproducts-alcoa.com/productsandalloys/alloy6013techsheet.pdf, September 2004 (2001)

German Institute for Standardization, Materials Handbook of German Aviation, Vol 2 (No. 1) Werkstoff-Handbuch der Deutschen Luftfahrt, Teil 1, Bd 2, Deutsches Institut für Normung, Beuth-Verlag GmbH, 1964 (in German)

R.R. Sawtell and J.T. Staley, Interactions Between Quenching and Aging in Alloy 7075, Aluminum, Vol 59 (No. 2), 1983, p 127–133

T. Herding, O. Kessler, F. Hoffmann, and P. Mayr, An Approach for Continuous Cooling Transformation (CCT) Diagrams of Aluminum Alloys, Mater. Sci. Forum, Vol 396–402, 2002, p 869–874

Aluminum and Aluminum Alloys-Castings-Chemical Composition and Mechanical Properties “Aluminum und Aluminumlegierungen-Gusstücke-Chemische Zusammensetzung und mechanische Eigenschaften,” DIN EN 1706, Ausgabe: 1998–06, Beuth Verlag GmbH, 1997 (in German)

D.S. Mackenzie, Metallurgical Principles of Quenching Aluminum Alloys, Proceedings of the 16th ASM Heat Treating Society Conference & Exposition, 19–21 March 1996 (Cincinnati, OH), ASM International, 1996, p 213–219

H. Beitz, Heat Treatment of AGe Hardenable Aluminum Alloys—Preferably Without Distortion, Werkstoff-Seminare, München, 1991, p 181–196

F. Ostermann, Application Technology Aluminum, Anwendungstechnologie Aluminum, Springer-Verlag, 1998, p 64 (in German)

O. Kessler, F. Hoffmann, and P. Mayr, Distortion of the Uncoated and CVD Coated Tool Steel D2 After Gas Quenching, Maß-und For-mänderungen bei der Gasabschreckung des unbeschichteten und CVD-beschichteten X155CrVMo12-1, Härt.-Tech. Mitt., Vol 50 (No. 6), 1995, p 337–343

S. Segerberg and E. Troell, High-Pressure Gas Quenching Using a Cold Chamber to Increase Cooling Capacity, Heat Treat. Met., Vol 24 (No. 1), 1997, p 21–24

F. Preißer, K. Löser, S. Segerberg, and E. Troell, High-Pressure Gas Quenching of Case Hardened Steels and Tempered Steels in Cold Chambers, Hochdruck-Gasabschrecken von Einsatz-und Vergütungsstählen in kalten Kammern, Härt.-Tech. Mitt., Vol 52 (No. 5), 1997, p 264–269

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Irretier, A., Kessler, O., Hoffmann, F. et al. Dry and clean age hardening of aluminum alloys by high-pressure gas quenching. J. of Materi Eng and Perform 13, 530–536 (2004). https://doi.org/10.1361/10599490420601

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1361/10599490420601