Abstract

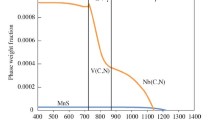

The crystal structures, morphologies, and compositions of carbides in a martensitic pipe steel of type X20CrMoV12.1 after long-term service at 550 °C have been carefully investigated using transmission electron microscopy (TEM) and dispersive x-ray spectrometry (EDS). Most of carbides are M23C6. The M23C6 particles in prior austenite grains and in martensite lath boundaries are extensively coarsened. Most of the finer carbides within the matrix are also identified as M23C6, and no other type of carbide was found except for some tiny plate-like V-rich carbides identified as MC. The V and O mass fractions in the M23C6 carbides have variable morphologies and locations, which might be due to their coarsening process. They are coarsening at different rates even after long-term exposure at elevated temperature. The formation of V-rich MC during the long-term service contributes to hardness maintenance and is good for microstructural stability.

Similar content being viewed by others

References

S. Straub, M. Meier, J. Ostermann, and W. Blum: “Entwicklung der Microstruktur und der Festigkeit des Stahles X20CrMoV12.1 bei 823K Während Zeitstandbeans pruchung und Gl#369hung,” VGB Kraitwerkstechnik, 1993, 73(8), p. 744 (in German).

E. El-Magd, G. Nicolini, and M.A. Nasser: “The Influence of Prior Aging on Microstructure, Tensile Properties and Hot Hardness of Alloy 800HT,” Metall., 1996, 50(11), p. 805.

D.B. Hahn and D.W. Bendick: “Erfahrungen aus der Zustandsbewertung eines FD- und HZÜ-Rohrleitungssystems aus dem Werkstoff X20CrMoV12.1 nach einer Bertriebszeit von über 180,000 h,” VGB Kraftwerkstechnik, 2000, 11, p. 85 (in German).

K. Borggreen and P.B. Mortensen: Long-Term Properties of Fracture of X20CrMoV12.1. The Danish Corrosion Center, Nov 1989.

R.B. Carruthers and M.J. Collins: “Carbide Transformations in Microstructurally Unstable Low Alloy Ferritic Steel,” Met. Sci., 1983, 17(3), p. 107.

R.C. Thomson and H.K.D.H. Bhadeshia: “Carbide Precipitation in 12CrMoV Power Plant Steel,” Metall. Trans., 1992, 23A(4), pp. 1171–79.

A. Strang and V. Vodarek: “Microstructural Stability of Creep Resistant Martensitic 12%Cr Steels” in Microstructure of High Temperature Materials, No. 2, A. Strang, J. Cawley, and G.W. Greenwood, ed., The Institute of Metals, London, UK, 1998, pp. 117–33.

P. Bianchi, P. Bontempi, A. Benvenuti, and N. Ricci: “Microstructural Evolution of P91 Steel After Long Term Creep Tests” in Microstructure of High Temperature Materials, No. 2, A. Strang, J. Cawley, and G.W. Greenwood, ed., The Institute of Metals, London, UK, 1998, pp. 107–16.

V. Vodarek and A. Strang: “Effect of Nickel on the Precipitation Processes in 12CrMoV Steels During Creep at 550,” Scripta Materialia, 1998, 38(1), p. 101.

L.K. Singhal and J.W. Martin: “The Nucleation and Growth of Widmannstätten M23C6 Precipitation in an Austenitic Stainless Steel,” Acta Metall., 1968, 16(9), p. 1159.

G. Eggeler: “The Effect of Long-Term Creep on Particle Coarsening in Tempered Martensite Ferritic Steels,” Acta Metall., 1989, 37(12), p. 3225.

P. Battaini, D. Dangelo, G. Marino, and J. Hald: “Interparticle Distance Evolution on Steam Pipes 12% Cr During Power Plants’ Service Time” in Creep and Fracture of Engineering Materials and Structures, Proc. 4th Inter. Conf., B. Wilshire and R.W. Evans, ed., Apr 1990, The Institute of Metals, London, UK, pp. 1039–54.

P.J. Ennis, A.Z. Lipies, and A.C. Filemonowicz: “Quantitative Comparison of the Microstructures of High Chromium Steels for Advanced Power Stations” in Microstructure of High Temperature Materials, No. 2, A. Strang, J. Cawley, and G.W. Greenwood, ed., The Institute of Metals, London, UK, 1998, pp. 135–44.

P. Klimanek, K. Cyrener, C. Germain, K. Jenkner, U. Martin, O. Oettel, A. Ostwaldt, D. Ostwaldt, and W. Pantleon: “Flow Behaviour and Microstructure of the Heat-Resistant Steels X20CrMoV12.1 and X5NiCrTiAl32.20 (Alloy 800)” in Microstructural and Mechanical Properties of Metallic High-Temperature Materials, H. Mughrabi, ed., New York, NY, 1999, pp. 272–89.

A. Hede and B. Aronsson: “Microstructure and Creep Properties of Some 12% Chromium Martensitic Steels,” JISI, 1969, 207(9), p. 1641.

A. Strang and V. Vodareks: “Precipitation Process in Martensitic 12CrMoVNb Steels During High Temperature Creep” in Microstructural Development and Stability in High Chromium Ferritic Power Plant Steels, The Institute of Materials, London, UK, 1997, pp. 31–52.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zheng-Fei, H., Zhen-Guo, Y. Identification of the precipitates by TEM and EDS in X20CrMoV12.1 after long-term service at elevated temperature. J. of Materi Eng and Perform 12, 106–111 (2003). https://doi.org/10.1361/105994903770343556

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105994903770343556