Abstract

An IR (IR) thermography technique, as a nondestructive evaluation technique, was applied to investigate the fatigue damage of reactor pressure vessel (RPV) steels during 20 Hz and 1000 Hz fatigue testing. Five stages of temperature profile were observed: an initial increase of the average specimen temperature, a region of temperature decrease, an equilibrium (steady-state) temperature region, an abrupt increase of the temperature, and a drop of temperature following specimen failure. The relationship between the temperature, stress-strain state, and fatigue behavior is discussed. Both thermodynamic and heat-transfer theories are applied to model the observed temperature variation during fatigue. The stress-strain state of the material has been back-calculated from the observed temperature profiles. The predicted and measured temperature evolutions and mechanical behavior during fatigue were found to be in good agreement. Thermography appears to provide a useful method of investigating the stress-strain behavior during fatigue.

Similar content being viewed by others

References

S. Suresh: Fatigue of Materials, 2nd ed., Cambridge University Press, Cambridge, UK, 1998.

W.A. Logsdon, P.K. Liaw, and J.A. Begley: “Fatigue Crack Growth Behavior of Pressure Vessel Steels and Submerged Arc Weldments in a High-Temperature Pressurized Water Environment,” ASTM STP 969, 1988, pp. 830–67.

P.K. Liaw, W.A. Logsdon, and J.A. Begley: “Fatigue Crack Growth Behavior of Pressure Vessel Steels and Submerged Arc Weldments in a High-Temperature Pressurized Water Environment,” Metall. Trans., 1989, 20A, pp. 2069–85.

P.K. Liaw and W.A. Logsdon: “The Influence of Load Ratio and Temperature on the Near-Threshold Fatigue Crack Growth Rate Properties of Pressure Vessel Steels,” J. Eng. Mater. Tech., ASME, 1985, 107, pp. 26–33.

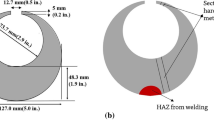

P.K. Liaw, C.Y. Yang, S.S. Palusamy, and W. Ren: “Fatigue Crack Initiation and Propagation Behavior of Pressure Vessel Steels,” Eng. Fracture Mech., 1997, 57, pp. 85–104.

W.A. Logsdon and P.K. Liaw: “Fatigue Crack Growth Rate Properties of SA508 and SA533 Pressure Vessel Steels and Submerged Arc Weldments in Room and Elevated Temperature Air Environments,” Eng. Fracture Mech., 1985, 22, pp. 509–26.

J.Y. Huang, C.Y. Chen, K.F. Chien, R.C. Kuo, P.K. Liaw, and J.G. Huang: “Fatigue Behavior of Reactor Pressure Vessel Steels,” Proc. of Julia Weertman Symp., Minerals, Metals, and Materials Society (TMS) Fall Meeting, Y.W. Chung, D. Dunand, P.K. Liaw, and G. Olson, ed., Cincinnati, OH, 31 Oct–4 Nov 1999, pp. 373–84.

J.Y. Huang, R.Z. Li, K.F. Chien, R.C. Kuo, P.K. Liaw, B. Yang, and J.G. Huang: “Fatigue Behavior of SA533-B1 Steels” in Fatigue Fracture Mechanics, 32nd Vol., STP 1406, R. Chona, ed., ASTM, West Conshohocken, PA, 2001, pp. 105–21.

L. Jiang, M. Huang, C.R. Brooks, and P.K. Liaw: “Acoustic Emission Detection of Fatigue Damage,” Proc. Nondestructive Evaluation (NDE) and Materials Properties IV Symp., TMS Annual Meeting, P.K. Liaw, R.J. Arsenault, R.E. Green, Jr., K.L. Murty, and R.B. Thompson, ed., San Diego, CA, 28 Feb–4 Mar, 1999, pp. 43–60.

M.E. Fine, Z.M. Connor, and J.D. Achenbach: “Early Stages of Fatigue Damage in Riveted Alclad 2024-T3 Aluminum Alloy Lap Joint Specimens,” Proc. Nondestructive Evaluation (NDE) and Materials Properties IV Symp., TMS Annual Meeting, P.K. Liaw, R.J. Arsenault, R.E. Green, Jr., K.L. Murty, and R.B. Thompson, ed., San Diego, CA, 28 Feb–4 Mar, 1999, pp. 1–9.

G. Birnbaum and G. Free: “Eddy-Current Characterization of Materials and Structures,” Symposium Sponsored by ASTM Committee E-7 on Nondestructive Testing, American Society for Testing and Materials, Gaithersburg, MD, 5–7 Sept 1979.

A.A. Moss and H.I. Goldberg: Computed Tomography, Ultrasound and X-ray: An Integrated Approach, Masson Publication, NY, 1979.

M.P. Luong: “Fatigue Limit Evaluation of Metals Using an Infrared Thermographic Technique,” Mech. Mater., 1998, 28(1–4), pp. 155–63.

K.S. Hermanson and B.I. Sandor: “Corrosion Fatigue Modeling via Differential Infrared Thermography,” Exp. Tech., 1998, 22(3), pp. 19–21.

X. Tung, D. Wang, and H. Xu: “Heat Energy Dissipation in Fatigue Damage Process of Materials,” Acta Metall. Sinica (China), 1992, 28(4), pp. 163–69.

D. Zhang and B.I. Sandor: “Damage Evaluation in Composite Materials Using Thermoplastic Stress Analysis,” ASTM STP 1122, 1991, pp. 341–53.

P.K. Liaw, R.J. Arsenault, R.E. Green, Jr., K.L. Murty, and R.B. Thompson, ed.: “Symp. Nondestructive Evaluation (NDE) and Materials Properties IV, TMS Annual Meeting,” San Diego, CA, 28 Feb–4 Mar, 1999.

I. Todhunter and K. Pearson: A History of the Elasticity and Strength of Materials, Vol. 2, Cambridge University Press, Cambridge, UK, 1893.

M.A. Biot: “Thermoelasticity and Irreversible Thermodynamics,” J. Appl. Phys., 1956, 27(3), pp. 240–53.

R. Rocca and M.B. Bever: “The Thermoelastic Effect in Iron and Nickel as a Function of Temperature,” Trans. Am. Instit. Mech. Eng., 1950, 188, pp. 327–33.

D.H. Allen and W.E. Haisler: “A Theory For Analysis of Thermoplastic Materials,” Mech. Struct., 1981, 13, pp. 129–35.

E.G. Henneke, K.L. Reifsnider, and W.W. Strinchcomb: “Thermography—NDI Method for Damage Detection,” J. Met., 1979, 31, pp. 11–15.

R.H. Blanc and E. Giacometti, “Infrared Radiometry Study of the Thermomechanical Behavior of Materials and Structures” in 1st Int. Conf. of Stress Analysis by Thermoelastic Technics, Sira Ltd., London, UK, Nov 1984.

B. Nayroles, R. Bouc, H. Caumon, J.C. Chezeaux, and E. Giacometti: “Infrared Telethermography and Structural Mechanics,” Int. J. Eng. Sci., 1981, 19, pp. 929–47.

D.T. Lohr, N.F. Enke, and B.I. Sandor: “Analysis of Fatigue Damage Evolution by Differential Infrared Thermography,” in Dynamic Failure, Proc. 1987 SEM Fall Conference, Savannah, GA, 25–27 Oct, 1987, pp. 169–74.

P.K. Liaw, H. Wang, L. Jiang, B. Yang, J.Y. Huang, R.C. Kuo, and J.G. Huang: “Thermographic Detection of Fatigue Damage of Pressure Vessel Steels at 1,000 Hz and 20 Hz,” Scripta Mater., 2000, 42, pp. 389–95.

H. Wang, L. Jiang, P.K. Liaw, C.R. Brooks, and D.L. Klarstrom: “Infrared Temperature Mapping of ULTIMET Alloy During High-Cycle Fatigue Tests,” Metall. Mater. Trans. A, 2000, 31, pp. 1307–10.

M.P. Luong: “Short-Time Measurement of Fatigue Limit of Metals Using Infrared Thermography,” Rev. Métall. Cah. Inf. Tech., 1995, 92(2), pp. 203–12.

J.M. Morgon and W.W. Millison: “A 1 kHz Servohydraulic Fatigue Testing System,” in Symp. Proc. in Honor of Professor Paul C. Paris, TMS Fall Meeting, W.O. Soboyejo and T.S. Srivatsan, ed., Indianapolis, IN, 14–18 Sept 1997, pp. 305–12.

L. Jiang, H. Wang, P.K. Liaw, C.R. Brooks, and D.L. Klarstrom: “Characterization of the Temperature Evolution During High-Cycle Fatigue of the ULTIMET Superalloy: Experiment and Theoretical Modeling,” Metall. Mater. Trans. A, 2001, 32(9), pp. 2279–96.

B. Yang, P.K. Liaw, H. Wang, L. Jiang, J.Y. Huang, R.C. Kuo, and J.G. Huang: “Thermographic Investigation of The Fatigue Behavior of Reactor Pressure Vessel Steels,” Mater. Sci. Eng. A, 2001, 314, pp. 131–39.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Yang, B. Thermographic detection of fatigue damage of reactor pressure vessel (RPV) steels. J. of Materi Eng and Perform 12, 345–353 (2003). https://doi.org/10.1361/105994903770343213

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994903770343213