Abstract

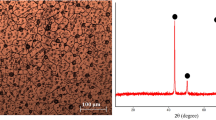

Fe-1.5Mo-0.7C steels with different porosity can successfully be prepared by using traditional compacting, vacuum sintering, and in part Hot Isostatically Pressing (HIPing). Their dry sliding wear behavior in both as-sintered and heat treated states were investigated. When porosity is lower than 6.2%, further decreases of porosity have less influence on the wear coefficient of both as-sintered and heat treated steels. Pores in the sintered steels collect the debris during the rubbing process, and therefore the disadvantage in wear process due to the poor hardness and mechanical strength caused by high porosity is partly compensated for. During dry sliding the as-sintered steels have three types of wear mechanisms (i.e., oxidational wear, abrasive wear, and delamination wear), while oxidational wear and delamination wear are the main regimes in heat treated steels. Oxidation leads to the wear of sintered steels and in the meantime the oxides attached to the rubbing surface further lower intense wear of the rubbing system. Abrasive wear and delamination wear, which result in flake debris, are responsible for high wear coefficients.

Similar content being viewed by others

References

B.M. Astashkevich: “Porosity Effect on Properties of Sintered Materials for Internal Combustion Engine Piston Rings,” Metallovedenie i Termicheskaya Obrabotka Metallov, 1996, 7, pp. 20–23 (in Russian).

H. Danninger, D. Spoljaric, A. Arakil, and B. Weiss: “Mo Alloyed PM Structural Steels Prepared by Different Alloying Techniques,” Adv. Powder Metall. & Particulate Mater., 1996, 13, pp. 177–88.

H. Danninger, D. Spoljaric, G. Jangg, B. Weiss, and R. Stickler: “High Cycle Fatigue Behavior of Mo Alloyed Sintered Steel,” Z. Metallkd., 1998, 89(2), pp. 135–41.

C. Amsallem, A. Gaucher, and G. Guilhot: “The Unlubricated Frictional Behavior of Sintered Iron,” Wear, 1973, 23, pp. 97–112.

M. Vardavoulias, C. Jouanny-Tresy, and M. Jeandin: “Sliding-Wear Behavior of Ceramic Particle-Reinforced High-Speed Steel Obtained by Powder Metallurgy,” Wear, 1993, 165, pp. 141–49.

S.C. Lim and J.H. Brunton: “The Unlubricated Wear of Sintered Iron,” Wear, 1986, 113, pp. 371–82.

Anon: “Standard Test Method for Wear Testing With a Pin-On-Disk Apparatus” in Friction and Wear Testing, Source Book of Selected References from ASTM Standards and ASM Handbooks, S. Lampman, ed., 1997, pp. 124–28.

J. Wang and H. Danninger: “Dry Sliding Wear Behavior of Molybdenum Alloyed Sintered Steels,” Wear, 1998, 222, pp. 49–56.

S.C. Lim and M.F. Ashby: “Wear-Mechanism Maps,” Acta Metall., 1987, 35, pp.1–24.

H. Danninger, D. Spoljaric, G. Jangg, B. Weiss, and R. Stickler: “Characterization of Pressed and Sintered Ferrous Materials by Quantitative Fractography,” Prakt. Metallographie, 1994, 31(2), pp. 56–69.

H. Uetz and K. Sommer: “Investigations of the Effect of Surface Temperatures in Sliding Contact,” Wear, 1977, 43, pp. 375–88.

J. Wang: “Dry Wear Sliding Behavior of High Strength Sintered Steels,” Ph.D. Thesis, Vienna University of Technology, Vienna, Austria, 1999.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, J., He, Y. & Danninger, H. Influence of porosity on the sliding wear behavior of sintered Fe-1.5Mo-0.7C steels. J. of Materi Eng and Perform 12, 339–344 (2003). https://doi.org/10.1361/105994903770343204

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994903770343204