Abstract

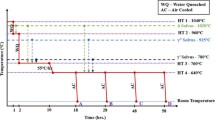

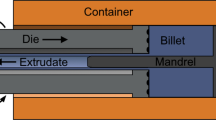

For semi-solid metal forming, it is essential to fabricate the semi-solid materials with spheroidal microstructure. Among several fabrication techniques of the semi-solid materials, (strain-induced melt activation (SIMA) is an ideal candidate with the advantages of simplicity and low equipment costs. In this paper, the microstructure evolution of LY11 alloy (approximately corresponding to ASTM 2017) was investigated in the SIMA process, which had two essential stages: deformation and isothermal heat treatment. The deformation stage was conducted using a CSS-1100C material testing machine and the isothermal heat treatment stage was performed in a resistance furnace. Different levels of deformation temperatures, ram velocities, isothermal temperatures, and holding times were used in this investigation. The microstructure of LY11 alloy was observed by a NEOPHOT-1 optical microscope. The results indicated that the processing parameters must be selected properly to obtain the fine, uniform and spheroidal microstructure by SIMA. The deformation-recrystallization mechanism for microstructure evolution in SIMA process was supported by experimental evidence.

Similar content being viewed by others

References

M.C. Flemings: “Behavior of Metal Alloys in the Semi-Solid State,” Metall. Trans., 1991, 22A, pp. 957–81.

D.H. Kirkwood: “Semi-Solid Metal Processing,” Int. Mater. Rev., 1994, 39, pp. 173–89.

S.Y. Lee, J.H. Lee, and Y.S. Lee: “Characterization of Al 7075 Alloys After Cold Working and Heating in the Semi-Solid Temperature Range,” J. Mater. Proc. Technol., 2001, 111, pp. 42–47.

E.R. Cau and M.H. Robert: “Obtention of Rheocasting Structures of M-2 and 308-L Stainless Steel by SIMA” in Proc. 2nd Int. Conf. on Semi-solid Processing of Alloys and Composites, MIT, Cambridge, MA, 1992, pp. 119–29.

S.J. Luo, W.T. Tian, and G.A. Zhang: “Structural Evolution of LC4 Alloy in Making Thixotropic Billet by SIMA Method,” Trans. Nonferrous. Met. Soc. China, 2001, 11, pp. 547–50.

T.A. Witten and L.M. Sander: “Diffusion-Limited Aggregation, a Kinetic Critical Phenomenon,” Phys. Rev. Lett., 1981, 47, pp. 1400–03.

R.D. Doherty, H.I. Lee, and E.A. Feest: “Microstructure of Stir-Cast Metals,” Mater. Sci. Eng., 1984, 65, pp. 181–89.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jiang, H., Li, X., Xiong, A. et al. Fabrication and microstructure evolution of semi-solid LY11 alloy by SIMA. J. of Materi Eng and Perform 12, 249–253 (2003). https://doi.org/10.1361/105994903770343088

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994903770343088