Abstract

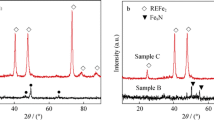

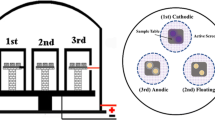

The properties of nitrided parts are closely related to the component phases of their compound layers and microstructure shape of their diffusion layers. Based upon the influence of nitriding temperature and nitrogen (N) potential on formation and decomposition of ion nitriding layer, the component phases and microstructure shape of ion nitrided layer, which was processed under cyclic N potential, was studied with x-ray diffraction (XRD) analysis and transmission electron microscopy (TEM). The mechanism of rapid ion nitriding is also discussed in this paper. The results show that if the rapid ion nitriding by the thermal cycling and the N potential cycling is controlled, the nitriding speed and nitrided layer thickness of materials can not only be enhanced compared to the conventional ion nitriding technique, but also the alloy nitrides can be obviously increased. The precipitation hardness phases of diffusion layer became more trivial and spread in all directions. It is very important to improve the quality of the nitrided layer and to enhance the properties of nitrided parts.

Similar content being viewed by others

References

L. Zhong, X. Han, S.Q. Zhou, and P.Z. Hu: “Rapid Ion Nitriding Under Cyclic Nitrogen Potential,” Heat Treatment of Metals, 1998, 10, pp. 9–11.

Y.H. Qi, L.K. Mong, T.T. Lei, and Y.S. Yuan: “An Effect on Gas Nitriding Brought by Step-Reciprocating Temperature-Change and High Purity Nitrogen Gas,” J. Liaoning Inst. Technol., 1999, 19(4), pp. 1–4.

F. Xie, B.D. Ma, and J.W. He: “Research Advancement of Steel Rapid and Deep Nitriding,” Mater. Bull., 1998, 5, pp. 19–22.

M.F. Yan, L.F. Xia, and G.C. Zhu: “Research on X-ray Analysis and Experimental of Ion Nitrided Surface’s Nitrogen Concentration,” Phys. Testing, 1990, 5, pp. 47–49.

Y.Y. Chen and G.H. Deng: “Reaction Diffusion and Nitriding Speed in Ion Nitriding,” J. Fuzhou University (Natural Science), 2001, 29(2), pp. 58–61.

S.Q. Zhou, Q. Ren, and Q.L. Fan: “X-ray Diffraction Analysis of 25Cr2MoVA Steel,” J. Chongqing University (Natural Science), 1998, 4, pp. 61–64.

L. Zhong, X. Han, S.Q. Zhou, and Q. Ren: “Research on Transformation Mechanism About ε Phase of 40Cr Steel Ion Nitriding Layer,” Hot Working Technol., 2002, 3, pp. 1–2.

M.J. Hu and J.S. Pan: Principle of Chemic Heat Treatment, Shanghai Jiaotong University Press, Shanghai, People’s Republic of China, 1996, p. 3.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhong, L., Han, X., Zhou, S. et al. Research on component phases and microstructure shape of a rapid ion nitriding layer. J. of Materi Eng and Perform 12, 687–692 (2003). https://doi.org/10.1361/105994903322692484

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105994903322692484