Abstract

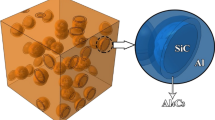

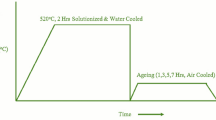

When the fabrication of a metal matrix composite (MMC) involves its cooling from a high temperature, plastic-elastic residual deformation fields can be generated within and around the particle due to the differential thermal expansion between the particle and matrix metal. The present investigation is concerned with the effect of thermal residual stresses on the thermal expansion and damping behavior of aluminite particulate-reinforced ZA-27 alloy MMCs. Composites were prepared by the compocasting technique with 1, 2, 3, and 4 wt.% of aluminite reinforcement. Thermal expansion and damping properties have been studied experimentally as a function of temperature over a temperature range 30 to 300 °C both in the heating and cooling cycle. The thermal expansion studies exhibited some residual strain, which increased with the increase in the weight percent of the reinforcement. The damping capacity of both the composites and matrix alloy is found to increase with the increase in temperature during the heating cycle, whereas in the cooling cycle, damping behavior exhibits a maximum, which becomes more pronounced with the increase in the weight percentage of the reinforcement. The appearance of the maximum may be linked with dislocation generation and motion as a result of plastic deformation of the matrix at the metal/reinforcement interface. This phenomenon is attributed to the thermal stresses generated as a result of coefficient of thermal expansion (CTE) mismatch between the composite constituent phases. The thermal stresses have been estimated in both the cases using simple models.

Similar content being viewed by others

References

K.H.W. Seah, S.C. Sharma, P.R. Rao, and B.M. Girish: Mater. Design, 1995, vol. 16, pp. 277–81.

S.C. Sharma and A. Ramesh: J. Mater. Engg. and Performance, 2000, 9 (5), pp. 557–65.

S.C. Sharma, B.M. Girish, D.R. Somashekar, R. Kamath, and B.M. Satish, Wear, 1999, vol. 224, (1999) pp. 89–94.

G.M. Vyletel, J.E. Allison, and D.C. Van Aken: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 3143–54.

R.J. Perez, J. Zhang, M.N. Gungor, and E.J. Lavernia: Metall. Trans. A, 1993, vol. 24A, pp. 701–11.

H. Akbulut, M. Durman, and F. Yilmaz: Mater. Sci. Technol., 1998, vol. 14, pp. 299–305.

S.C. Sharma: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 773–80.

Rajendra U. Vaidya and K.K. Chawla: Comp. Sci. Technol., 1994, vol. 50, pp. 13–22.

Eun U. Lee: Metall. Trans. A, 1992, vol. 23A, pp. 2205–10.

E. Gervais, R.J. Barnhurst, and C.A. Loong: J. Met., 1985, vol. 37, pp. 43–47.

H. LeHuy and G.L. Esperance: J. Mater. Sci., 1991, vol. 26, pp. 559–68.

K.J. Altorfer: Met. Progr., Nov., pp. 29–31.

S.C. Sharma, B.M. Girish, B.M. Satish, and R. Kamath: J. Mater. Eng. Performance, 1998, vol. 7 (1), pp. 93–99.

S.C. Sharma, B.M. Satish, B.M. Girish, R. Kamath, and Hiroshi Asanuma: Tribol. Int., 1998, vol. 31 (4), pp. 183–88.

R.J. Arsenault and N. Shi: Mater. Sci. Eng., 1986, vol. 81, pp. 175–87.

Mary Vogelsang, R.J. Arsenault, and R.M. Fisher: Metall. Trans. A, 1986, vol. 17A, pp. 379–89.

H.M. Ledbetter and M.W. Austin: Mater. Sci. Eng., 1987, vol. 89, pp. 53–61.

S.C. Sharma, B.M. Girish, D.R. Somashekar, R. Kamath, and B.M. Satish: Composite Sci., 1999, vol. 8 (3), pp. 309–14.

M. Durman and S. Murphy: J. Mater. Sci., 1997, vol. 32, pp. 11603–11611.

Wang Hongmin, Luo Meihua, Chen Yungui, and Wu Yigui: J. Mater. Sci. Lett., 1996, vol. 15, p. 1008.

Yuanyuan Li, Tungwai Leo Nagi, Wei Xia, and Wen Zhang: Wear, 1996, vol. 198, pp. 126.

R.R. Tummala and A.L. Freidberg: J. Appl. Phys., 1970, vol. 41, (13), pp. 5104–07.

Z.M. Sun, J.B. Li, Z.G. Wang, and W.J. Li: Acta Metall. Mater., 1992, vol. 40 (11), pp. 2961–66.

L. Parrine and R. Schaller: Acta Mater., 1996, vol. 44 (12), pp. 4881–88.

L. Parrini and R. Schaller: Scripta Mater., 1993, vol. 28, pp. 763–67.

L. Parrine and R. Schaller: Acta Mater., 1996, vol. 44 (10), pp. 3895–3903.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sastry, S., Krishna, M. & Uchil, J. Effect of thermal stresses on the thermal expansion and damping behavior of ZA-27/aluminite metal matrix composites. J. of Materi Eng and Perform 10, 220–224 (2001). https://doi.org/10.1361/105994901770345240

Received:

Issue Date:

DOI: https://doi.org/10.1361/105994901770345240