Abstract

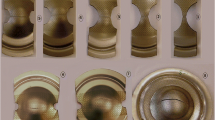

The indentation and perforation of ductile metal sheet with a conical tool is accompanied by elastoplastic bending, stretching, plastic flow, and crack initiation and propagation. This ultimately results in material fracture in the form of petals. It has been observed that the perforation process is dependent upon the angle of the conical tool. Fracture toughness, crack initiation, work input before and after crack initiation, number of petals, and sheet and petal bending angles all depend on the tool angle. Crack initiation has resulted at minimum tool displacement for a tool angle α=45°, while minimum work input before and after the crack initiation is observed when the tool has an angle α=35°. The optimum range of tool angles for the indentation process is α=22.5 to 50°. In this range, the aluminum sheets showed minimum fracture toughness as well as minimum work input to overcome the offered resistance.

Similar content being viewed by others

References

M. Afzal Khan, M.M. Nazeer, Athar Naeem, A.-ul Haq, and A. G. Atkins: Proc. Eur Conf. Advanced Materials and Processes [EUROMAT 95], Symp. D, Padua/Venice, Italy, Associazione Tlaliana di Metallurgia, 1-20121 Milano Plazzale Rodollo Morandi, 2, 1995, pp. 491–94.

A.G. Atkins: Future Trends in Applied Mechanics (P.S. Theocaris Festschrift), National Technical University of Athens, Athens, 1989.

M. Afzal Khan: Ph.D. Thesis, Reading University, Reading, United Kingdom, 1996, pp. 262–341.

Malik M. Nazeer, M. Afzal Khan, Athar Naeem, and A.-ul Haq: Int. J. Mech. Sci., 2000, vol. 42, pp. 1391–1403.

Malik M. Nazeer, Athar Naeem, M. Afzal Khan, A.-ul Haq, and A.G. Atkins: Proc. 5th Int. Symp. Advanced Materials, Islamabad, Pakistan, M. Afzal Khan, A.-ul Haq, K. Hussain, and A.Q. Khan, eds., Dr. A.Q. Khan Research Laboratories, Kahuta, Pakistan, 1997, pp. 552–59.

Malik M. Nazeer, Athar Naeem, M. Afzal Khan, A.-ul Haq, and A.G. Atkins: Proc. 12th Nat. Conf. Engineering Fracture Mechanics, Jamshoro, Pakistan, 1997.

M. Afzal Khan, Athar Naeem, Malik M. Nazeer, A.-ul Haq, and A.G. Atkins: Proc. 3rd Int. Symp. Advanced Materials, Islamabad, Pakistan, A.-ul Haq, F. Habiby, and A.Q. Khan, eds., Dr. A.Q. Khan Research Laboratories, Kahuta, Pakistan, 1993, pp. 706–13.

Malik M. Nazeer, M. Afzal Khan, Athar Naeem, A.-ul Haq, and A.G. Atkins: Proc. Int. Conf. Applied and Pure Mathematics, ICPAM 95, Bahrain, Bahrain University, Bahrain, in press.

A.G. Atkins, M. Afzal Khan, and J.M. Liu: Int. J. Impact Eng., 1998, vol. 21 (7), pp. 521–39.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Nazeer, M.M., Afzal Khan, M., Naeem, A. et al. Response of ductile metal sheet parameters to the cone angle of indenting conical tool and fracture toughness evaluation. J. of Materi Eng and Perform 9, 489–498 (2000). https://doi.org/10.1361/105994900770345601

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994900770345601