Abstract

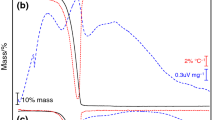

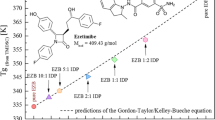

The present work aims to explore the new solid forms of telmisartan (TEL) with alpha-ketoglutaric acid (KGA) and glutamic acid (GA) as potential coformers using mechanochemical approach and their role in augmentation in physicochemical parameters over pure crystalline TEL. Mechanochemical synthesis was performed using 1:1 stoichiometric ratio of TEL and the selected coformers in the presence of catalytic amount of ethanol for 1 h. The ground product was characterized by PXRD, DSC, and FTIR. The new solid forms were evaluated for apparent solubility, intrinsic dissolution, and physical stability. Preliminary characterization revealed the amorphization of the mechanochemical product as an alternate outcome of cocrystallization screening. Mechanistic understanding of the amorphous phase highlights the formation of amorphous-mediated cocrystallization that involves three steps, viz., molecular recognition, intermediate amorphous phase, and product nucleation. The solubility curves of both multicomponent amorphous solid forms (TEL-KGA and TEL-GA) showed the spring-parachute effect and revealed significant augmentation in apparent solubility (8–10-folds), and intrinsic dissolution release (6–9-folds) as compared to the pure drug. Besides, surface anisotropy and differential elemental distributions in intrinsic dissolution compacts of both solid forms were confirmed by FESEM and EDX mapping. Therefore, amorphous phases prepared from mechanochemical synthesis can serve as a potential solid form for the investigation of a cocrystal through amorphous-mediated cocrystallization. This has greater implications in solubility kinetics wherein the rapid precipitation of the amorphous phase can be prevented by the metastable cocrystal phase and contribute to the significant augmentation in the physicochemical parameters.

Graphical Abstract

Similar content being viewed by others

Data Availability

All the data represented the result are available as a part of this article and not additional source data are required.

References

Desiraju GR. Crystal engineering: a holistic view. Angew Chem Int Ed Engl. 2007;46(44):8342–56. https://doi.org/10.1002/anie.200700534.

Corpinot MK, Bučar D-K. A practical guide to the design of molecular crystals. Cryst Growth Des. 2019;19(2):1426–53. https://doi.org/10.1021/acs.cgd.8b00972.

Kavanagh ON, Croker DM, Walker GM, Zaworotko MJ. Pharmaceutical cocrystals: from serendipity to design to application. Drug Discov Today. 2019;24(3):796–804. https://doi.org/10.1016/j.drudis.2018.11.023.

Duggirala NK, Perry ML, Almarsson Ö, Zaworotko MJ. Pharmaceutical cocrystals: along the path to improved medicines. Chem Commun. 2016;52(4):640–55. https://doi.org/10.1039/C5CC08216A.

Nangia A, Desiraju G. Crystal engineering: an outlook for the future. Angew Chem Int Ed Engl. 2019;58(13):4100–7. https://doi.org/10.1002/anie.201811313.

https://www.fda.gov/files/drugs/published/Regulatory-Classification-of-Pharmaceutical-Co-Crystals.pdf. 2018. Accessed 25 Nov 2023.

Bolla G, Sarma B, Nangia AK. Crystal engineering of pharmaceutical cocrystals in the discovery and development of improved drugs. Chem Rev. 2022;122(13):11514–603. https://doi.org/10.1021/acs.chemrev.1c00987.

Karimi-Jafari M, Padrela L, Walker GM, Croker DM. Creating cocrystals: a review of pharmaceutical cocrystal preparation routes and applications. Cryst Growth Des. 2018;18(10):6370–87. https://doi.org/10.1021/acs.cgd.8b00933.

Malamatari M, Ross SA, Douroumis D, Velaga SP. Experimental cocrystal screening and solution based scale-up cocrystallization methods. Adv Drug Deliv Rev. 2017;117:162–77. https://doi.org/10.1016/j.addr.2017.08.006.

Delori A, Friščić T, Jones W. The role of mechanochemistry and supramolecular design in the development of pharmaceutical materials. CrystEngComm. 2012;14(7):2350–62. https://doi.org/10.1039/C2CE06582G.

Braga D, Maini L, Grepioni F. Mechanochemical preparation of co-crystals. Chem Soc Rev. 2013;42(18):7638–48. https://doi.org/10.1039/C3CS60014A.

Ferreira da Silva JA-O, Minas da Piedade MF, André VA-O, Domingos S, Martins ICB, Duarte MT. The Lisbon supramolecular green story: mechanochemistry towards new forms of pharmaceuticals. Molecules. 2020;25:2705.

Cherukuvada S, Guru Row TN. Comprehending the formation of eutectics and cocrystals in terms of design and their structural interrelationships. CrystGrowth Des. 2014;14(8):4187–98. https://doi.org/10.1021/cg500790q.

Cherukuvada S, Nangia A. Eutectics as improved pharmaceutical materials: design, properties and characterization. ChemCommun. 2014;50:906–23.

Wu W, Wang Y, Löbmann K, Grohganz HA-O, Rades TA-O. Transformations between co-amorphous and co-crystal systems and their influence on the formation and physical stability of co-amorphous systems. Mol Pharm. 2019;16:1294–304.

Löbmann K, Strachan C, Grohganz H, Rades T, Korhonen O, Laitinen R. Co-amorphous simvastatin and glipizide combinations show improved physical stability without evidence of intermolecular interactions. Eur J Pharm Biopharm. 2012;81(1):159–69. https://doi.org/10.1016/j.ejpb.2012.02.004.

Sharpe M, Jarvis B, Goa KL. Telmisartan: a review of its use in hypertension. Drugs. 2001;61(10):1501–29. https://doi.org/10.2165/00003495-200161100-00009.

Park J, Cho W, Cha KH, Ahn J, Han K, Hwang SJ. Solubilization of the poorly water soluble drug, telmisartan, using supercritical anti-solvent (SAS) process. Int J Pharm. 2013;441(1–2):50–5. https://doi.org/10.1016/j.ijpharm.2012.12.020.

Di L, Pv Fish, Mano T. Bridging solubility between drug discovery and development. Drug Discov Today. 2012;17:486–95. https://doi.org/10.1016/j.drudis.2011.11.007.

Chadha R, Bhandari S, Haneef J, Khullar S, Mandal S. Cocrystals of telmisartan: characterization, structure elucidation, in vivo and toxicity studies. CrystEngComm. 2014;16(36):8375–89. https://doi.org/10.1039/c4ce00797b.

Arora P, Kaur A, Haneef J, Chadha R. Solubility improvement of telmisartan by cocrystallization with citric acid. Int J Pharm Sci Res. 2017;8(9):3768–75. https://doi.org/10.13040/IJPSR.0975-8232.8(9).3768-75.

Dhibar M, Chakraborty S, Basak S. Assessment of effects of solvents on cocrystallization by computational simulation approach. Curr Drug Deliv. 2021;18(1):44–53.

Yu G, Chen X, He L, Li X, Zhou Z, Ren Z. Study on the solubilization of telmisartan by forming cocrystals with aromatic carboxylic acids. CrystEngComm. 2021;23(27):4871–8. https://doi.org/10.1039/D1CE00551K.

Dhibar M, Chakraborty SA-O, Basak S, Pattanayak P, Chatterjee T, Ghosh B, et al. Critical analysis and optimization of stoichiometric ratio of drug-coformer on cocrystal design: molecular docking, in vitro and in vivo assessment. Pharmaceuticals. 2023;16:284.

Haneef J, Chadha R. Drug-drug multicomponent solid forms: cocrystal, coamorphous and eutectic of three poorly soluble antihypertensive drugs using mechanochemical approach. AAPS PharmSciTech. 2017;18(6):2279–90. https://doi.org/10.1208/s12249-016-0701-1.

Ganesan T, Muthudoss P, Voguri RS, Ghosal S, Ann EYC, Kwok J, et al. A new febuxostat-telmisartan drug-drug cocrystal for gout-hypertension combination therapy. J Pharm Sci. 2022;111(12):3318–26.

Nugrahani IA-O, Jessica MA. Amino acids as the potential co-former for co-crystal development: a review. Molecules. 2021;26(11):3279.

Tilborg A, Norberg B, Wouters J. Pharmaceutical salts and cocrystals involving amino acids: a brief structural overview of the state-of-art. Eur J Med Chem. 2014;74:411–26.

Zhang X, Shao H, Zheng X. Amino acids at the intersection of nutrition and insulin sensitivity. Drug Discov Today. 2019;24(4):1038–43. https://doi.org/10.1016/j.drudis.2019.02.008.

Bhatt NK, Haneef J, Vyas M, Khatik GL. Development of L-lysine amino acid-based co-crystal of telmisartan using crystal engineering approach to improve solubility, dissolution, and micrometric properties. Curr Drug Deliv. 2021;18(5):596–606.

Khanfar M, Al-Remawi M, Al-Akayleh F, Hmouze S. Preparation and evaluation of co-amorphous formulations of telmisartan-amino acids as a potential method for solubility and dissolution enhancement. AAPS PharmSciTech. 2021;22(3):112.

Thakral NK, Zanon RL, Kelly RC, Thakral S. Applications of powder X-ray diffraction in small molecule pharmaceuticals: achievements and aspirations. J Pharm Sci. 2018;107(12):2969–82.

Willart JF, Carpentier L, Danède F, Descamps M. Solid-state vitrification of crystalline griseofulvin by mechanical milling. J Pharm Sci. 2012;101(4):1570–7. https://doi.org/10.1002/jps.23041.

Newman A, Reutzel-Edens SM, Zografi G. Coamorphous active pharmaceutical ingredient-small molecule mixtures: considerations in the choice of coformers for enhancing dissolution and oral bioavailability. J Pharm Sci. 2018;107(1):5–17. https://doi.org/10.1016/j.xphs.2017.09.024.

Mukherjee A, Tothadi S, Chakraborty S, Ganguly S, Desiraju GR. Synthon identification in co-crystals and polymorphs with IR spectroscopy. Primary amides as a case study. CrystEngComm. 2013;15(23):4640–54. https://doi.org/10.1039/C3CE40286J.

Baghel S, Cathcart H, Redington W, O’Reilly NJ. An investigation into the crystallization tendency/kinetics of amorphous active pharmaceutical ingredients: a case study with dipyridamole and cinnarizine. Eur J Pharm Biopharm. 2016;104:59–71. https://doi.org/10.1016/j.ejpb.2016.04.017.

Jensen LG, Skautrup FB, Müllertz A, Abrahamsson B, Rades T, Priemel PA. Amorphous is not always better-a dissolution study on solid state forms of carbamazepine. Int J Pharm. 2017;522(1–2):74–9. https://doi.org/10.1016/j.ijpharm.2017.02.062.

Yu L. Amorphous pharmaceutical solids: preparation, characterization and stabilization. Adv Drug Deliv Rev. 2001;48(1):27–42. https://doi.org/10.1016/s0169-409x(01)00098-9.

Jayasankar A, Somwangthanaroj A, Shao ZJ, Rodríguez-Hornedo N. Cocrystal formation during cogrinding and storage is mediated by amorphous phase. Pharm Res. 2006;23(10):2381–92.

Ding F, Cao W, Wang R, Wang N, Li A, Wei Y, et al. Mechanistic study on transformation of coamorphous baicalein-nicotinamide to its cocrystal form. J Pharm Sci. 2023;112(2):513–24. https://doi.org/10.1016/j.xphs.2022.08.031.

Seefeldt K, Miller J, Alvarez-Núñez F, Rodríguez-Hornedo N. Crystallization pathways and kinetics of carbamazepine-nicotinamide cocrystals from the amorphous state by in situ thermomicroscopy, spectroscopy, and calorimetry studies. J Pharm Sci. 2007;96(5):1147–58.

Friščić T, Jones W. Recent advances in understanding the mechanism of cocrystal formation via grinding. Cryst Growth Des. 2009;9(3):1621–37. https://doi.org/10.1021/cg800764n.

Descamps M, Willart JF. Perspectives on the amorphisation/milling relationship in pharmaceutical materials. Adv Drug Deliv Rev. 2016;100:51–66.

Babu NJ, Nangia A. Solubility advantage of amorphous drugs and pharmaceutical cocrystals. Cryst Growth Des. 2011;11(7):2662–79. https://doi.org/10.1021/cg200492w.

Greco K, Bogner R. Solution-mediated phase transformation: significance during dissolution and implications for bioavailability. J Pharm Sci. 2012;101(9):2996–3018.

Hall VJ, Simpson GJ. Direct observation of transient Ostwald crystallization ordering from racemic serine solutions. J Am Chem Soc. 2010;132(39):13598–9.

Chen Y, Chen Z, Tylinski M, Ediger MA-O, Yu LA-O. Effect of molecular size and hydrogen bonding on three surface-facilitated processes in molecular glasses: surface diffusion, surface crystal growth, and formation of stable glasses by vapor deposition. J Chem Phys. 2019;150(2):024502.

Sun Y, Zhu L, Wu T, Cai T, Gunn EM, Yu L. Stability of amorphous pharmaceutical solids: crystal growth mechanisms and effect of polymer additives. AAPS J. 2012;14(3):380–8.

Andronis V, Yoshioka M, Zografi G. Effects of sorbed water on the crystallization of indomethacin from the amorphous state. J Pharm Sci. 1997;86(3):346–51. https://doi.org/10.1021/js9602711.

Yu L. Surface mobility of molecular glasses and its importance in physical stability. Adv Drug Deliv Rev. 2016;100:3–9.

Acknowledgements

The authors highly acknowledge the services (PXRD and FESEM) provided by the Sophisticated Analytical Instrumentation Facility (SAIF), Panjab University, India, to carry out the sample analysis.

Funding

JH received a UGC Startup Research Grant (BSR: 30–520/2020) from the University Grants Commission, New Delhi.

Author information

Authors and Affiliations

Contributions

Jamshed Haneef: conceptualization, funding acquisition, writing—review and editing. Shakir Ali: data curation, writing—original draft.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Haneef, J., Ali, S. Multicomponent Amorphous Solid Forms of Telmisartan: Insights into Mechanochemical Activation and Physicochemical Attributes. AAPS PharmSciTech 25, 84 (2024). https://doi.org/10.1208/s12249-024-02799-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-024-02799-6