Abstract

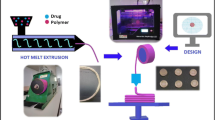

Three-dimensional (3D) printing technology has presently been explored widely in the field of pharmaceutical research to produce various conventional as well as novel dosage forms such as tablets, capsules, oral films, pellets, subcutaneous implants, scaffolds, and vaginal rings. The use of this innovative method is a good choice for its advanced technologies and the ability to make tailored medicine specifically for individual patient. There are many 3D printing systems that are used to print tablets, implants, and vaginal rings. Among the available systems, the fused deposition modeling (FDM) is widely utilized. The FDM has been regarded as the best choice of printer as it shows high potential in the production of tablets as a unit dose in 3D printing medicine manufacturing. In order to design a 3D-printed tablet or other dosage forms, the physicochemical properties of polymers play a vital role. One should have proper knowledge about the polymer’s properties so that one can select appropriate polymers in order to design 3D-printed dosage form. This review highlighted the various physicochemical properties of polymers that are currently used as filaments in 3D printing. In this manuscript, the authors also discussed various systems that are currently adopted in the 3D printing.

Similar content being viewed by others

Abbreviations

- API:

-

Active pharmaceutical ingredient

- HPMC:

-

Hydroxypropyl methylcellulose

- CTE:

-

Thermal expansion coefficient

- T g :

-

Glass transition temperature

- FDM:

-

Fused deposition modeling

- FFF:

-

Fused filament fabrication

- XRPD:

-

X-ray powder diffraction

- SLS:

-

Selective laser sintering

- CAD:

-

Computer-aided design

- PVP:

-

Polyvinylpyrrolidone

- T m :

-

Melting temperature

- SSE:

-

Semi-solid extrusion

- HME:

-

Hot melt extrusion

- BJP:

-

Binder jet printing

- PVA:

-

Polyvinyl alcohol

- SLA:

-

Stereolithography

- EC:

-

Ethyl cellulose

- PLA:

-

Polylactic acid

References

Aimar A, Palermo A, Innocenti B. The role of 3D printing in medical applications: a state of the art. J Healthc Eng. 2019;2019:1–10. Hindawi. https://doi.org/10.1155/2019/5340616.

Natterson-Horowitz B, Aktipis A, Fox M, Gluckman PD, Low FM, Mace R, et al. The future of evolutionary medicine: sparking innovation in biomedicine and public health. Front Sci Front. 2023;1:997136. https://doi.org/10.3389/fsci.2023.997136.

Muhindo D, Elkanayati R, Srinivasan P, Repka MA, Ashour EA. Recent advances in the applications of additive manufacturing (3D printing) in drug delivery: a comprehensive review. AAPS PharmSciTech. 2023;24:57. Springer.

Katakam P, Adiki SK, Satapathy SR. Recent advancements of additive manufacturing for patient-specific drug delivery. Addit Manuf Process Biomed Eng. 2022:1–26. Taylor & Francis Group.

Varghese R, Salvi S, Sood P, Karsiya J, Kumar D. Recent advancements in additive manufacturing techniques employed in the pharmaceutical industry: A bird’s eye view. Annals of 3D printed medicine. 2022;8:100081. Elsevier. https://doi.org/10.1016/j.stlm.2022.100081.

Sandler N, Preis M. Printed drug-delivery systems for improved patient treatment. Trends Pharmacol Sci. 2016;37:1070–80. Elsevier.

Araújo MRP, Sa-Barreto LL, Gratieri T, Gelfuso GM, Cunha-Filho M. The digital pharmacies era: How 3D printing technology using fused deposition modeling can become a reality. Pharmaceutics. 2019;11:1–14. MDPI. https://doi.org/10.3390/pharmaceutics11030128.

Goole J, Amighi K. 3D printing in pharmaceutics: a new tool for designing customized drug delivery systems. Int J Pharm. 2016;499:376–94. Elsevier.

Kerr T. Steam-Building’ Exercises. 3D print introd to access afford deskt 3D print. 2022:129–163. Springer. https://doi.org/10.1007/978-3-031-19350-7_10.

Nohut S, Schwentenwein M. Vat photopolymerization additive manufacturing of functionally graded materials: a review. J Manuf Mater Process. 2022;6:17. MDPI.

Zhao H, Zong G. 6 Metal additive manufacturing. Mater Adv Manuf. 2022;269–300. Taylor & Francis Group.

Mostafaei A, Elliott AM, Barnes JE, Li F, Tan W, Cramer CL, et al. Binder jet 3D printing—process parameters, materials, properties, modeling, and challenges. Prog Mater Sci. 2021;119:100707. Elsevier.

Jiang P, Ji Z, Wang X, Zhou F. Surface functionalization–a new functional dimension added to 3D printing. J Mater Chem C. 2020;8:12380–411. Royal Society of Chemistry.

Singh DD, Mahender T, Reddy AR. Powder bed fusion process: a brief review. Mater Today Proc. 2021;46:350–5. Elsevier.

Kumar K, Zindani D, Davim JP. Rapid prototyping, rapid tooling and reverse engineering. 2020;5. De Gruyter. https://doi.org/10.1515/9783110664904.

Fuenmayor E, O’Donnell C, Gately N, Doran P, Devine DM, Lyons JG, et al. Mass-customization of oral tablets via the combination of 3D printing and injection molding. Int J Pharm. 2019;569:118611. Elsevier.

Azad MA, Olawuni D, Kimbell G, Badruddoza AZM, Hossain M, Sultana T. Polymers for extrusion-based 3D printing of pharmaceuticals: a holistic materials–process perspective. Pharmaceutics. 2020;12:124. Multidisciplinary Digital Publishing Institute.

Tan DK, Maniruzzaman M, Nokhodchi A. Advanced pharmaceutical applications of hot-melt extrusion coupled with fused deposition modelling (FDM) 3D printing for personalised drug delivery. Pharmaceutics. 2018;10:203. Multidisciplinary Digital Publishing Institute.

Kozakiewicz-Latała M, Junak A, Złocińska A, Pudło W, Prusik K, Szymczyk-Ziółkowska P, et al. Adjusting the melting point of an Active Pharmaceutical Ingredient (API) via cocrystal formation enables processing of high melting drugs via combined hot melt and materials extrusion (HME and ME). Addit Manuf. 2022;60:103196. Elsevier.

Chia HN, Wu BM. Recent advances in 3D printing of biomaterials. J Biol Eng BioMed Central. 2015;9:1–14.

Ulery BD, Nair LS, Laurencin CT. Biomedical applications of biodegradable polymers. J Polym Sci Part B Polym Phys. 2011;49:832–64. Wiley Online Library.

Cunha-Filho M, Araújo MRP, Gelfuso GM, Gratieri T. FDM 3D printing of modified drug-delivery systems using hot melt extrusion: a new approach for individualized therapy. Ther Deliv. 2017;8:957–66. Future Science.

Goyanes A, Wang J, Buanz A, Martínez-Pacheco R, Telford R, Gaisford S, et al. 3D Printing of Medicines: Engineering Novel Oral Devices with Unique Design and Drug Release Characteristics. Mol Pharm. 2015;12:4077–84.

Khaled SA, Burley JC, Alexander MR, Yang J, Roberts CJ. 3D printing of five-in-one dose combination polypill with defined immediate and sustained release profiles. J Control Release. 2015;217:308–14. Elsevier.

Rahim TNAT, Abdullah AM, Md AH. Recent developments in fused deposition modeling-based 3D printing of polymers and their composites. Polym Rev. 2019;59:589–624. Taylor & Francis.

Kalaskar DM. 3D printing in medicine. Woodhead Publishing. 2022:422. Elsevier.

Ashammakhi N, Hernandez AL, Unluturk BD, Quintero SA, de Barros NR, Hoque Apu E, et al. Biodegradable implantable sensors: materials design, fabrication, and applications. Adv Funct Mater. 2021;31:2104149. Wiley Online Library.

Zhang J, Vo AQ, Feng X, Bandari S, Repka MA. Pharmaceutical additive manufacturing: a novel tool for complex and personalized drug delivery systems. AAPS PharmSciTech. 2018;19:3388–402. Springer.

Crama Y, Pochet Y, Wera Y. A discussion of production planning approaches in the process industry. 2001:1–36. http://hdl.handle.net/2078.1/4196.

Thomas D. Costs, benefits, and adoption of additive manufacturing: a supply chain perspective. Int J Adv Manuf Technol. 2016;85:1857–76. Springer.

Choonara YE, Du Toit LC, Kumar P, Kondiah PPD, Pillay V. 3D-printing and the effect on medical costs: a new era? Expert Rev Pharmacoeconomics Outcomes Res. 2016;16:23–32.

Alruwaili NK, Rizwanullah M, Abbas Bukhari SN, Amir M, Ahmed MM, Fazil M. 3D printing technology in design of pharmaceutical products. Curr Pharm Des. 2018;24:5009–18. Bentham Science Publishers.

Alam MS, Akhtar A, Ahsan I, Shafiq-un-Nabi S. Pharmaceutical product development exploiting 3D printing technology: conventional to novel drug delivery system. Curr Pharm Des. 2018;24:5029–38. Bentham Science Publishers.

El Aita I, Ponsar H, Quodbach J. A critical review on 3D-printed dosage forms. Curr Pharm Des. 2018;24:4957–78. Bentham Science Publishers.

Jamroz W, Kurek M, Łyszczarz E, Brniak W, Jachowicz R. Printing techniques: recent developments in pharmaceutical technology. Acta Pol Pharm Drug Res. 2017;74:753–63.

Jakus AE. An introduction to 3D printing—past, present, and future promise. 3D Print Orthop Surg. 2019:1–15. Elsevier. https://doi.org/10.1016/B978-0-323-58118-9.00001-4.

Górski F, Kuczko W, Weiss W, Wichniarek R, Żukowska M. Prototyping of an individualized multi-material wrist orthosis using fused deposition modelling. Adv Sci Technol Res J. 2019;13. https://doi.org/10.12913/22998624/113543.

Aguilar-de-Leyva Á, Linares V, Casas M, Caraballo I. 3D printed drug delivery systems based on natural products. Pharmaceutics. 2020;12:620. MDPI.

Goyanes A, Martinez PR, Buanz A, Basit AW, Gaisford S. Effect of geometry on drug release from 3D printed tablets. Int J Pharm. 2015;494:657–63. Elsevier.

Frazelle J. Out-of-this-world additive manufacturing. Commun ACM. 2021;64:58–62. ACM New York, NY, USA.

Doubrovski EL, Tsai EY, Dikovsky D, Geraedts JMP, Herr H, Oxman N. Voxel-based fabrication through material property mapping: a design method for bitmap printing. Comput Des. 2015;60:3–13. Elsevier.

Cox PJ, Khan KA, Munday DL, Sujja-Areevath J. Development and evaluation of a multiple-unit oral sustained release dosage form for S (+)-ibuprofen: preparation and release kinetics. Int J Pharm. 1999;193:73–84. Elsevier.

Konta AA, García-Piña M, Serrano DR. Personalised 3D printed medicines: which techniques and polymers are more successful? Bioengineering. 2017;4:79. Multidisciplinary Digital Publishing Institute.

Quodbach J, Bogdahn M, Breitkreutz J, Chamberlain R, Eggenreich K, Elia AG, et al. Quality of FDM 3D printed medicines for pediatrics: considerations for formulation development, filament extrusion, printing process and printer design. Ther Innov Regul Sci. 2022;56:910–28. Springer.

Tambe S, Jain D, Agarwal Y, Amin P. Hot-melt extrusion: highlighting recent advances in pharmaceutical applications. J Drug Deliv Sci Technol. 2021;63:102452. Elsevier.

Nober C, Manini G, Carlier E, Raquez J-M, Benali S, Dubois P, et al. Feasibility study into the potential use of fused-deposition modeling to manufacture 3D-printed enteric capsules in compounding pharmacies. Int J Pharm. 2019;569:118581. Elsevier.

Liu Z, Wang Y, Wu B, Cui C, Guo Y, Yan C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int J Adv Manuf Technol. 2019;102:2877–89. Springer.

Lu Q, Song K-Y, Feng Y, Xie J. Fabrication of suspended uniform polymer microfibers by FDM 3D printing. CIRP J Manuf Sci Technol. 2021;32:179–87. Elsevier.

Dumpa N, Butreddy A, Wang H, Komanduri N, Bandari S, Repka MA. 3D printing in personalized drug delivery: An overview of hot-melt extrusion-based fused deposition modeling. Int J Pharm. Elsevier; 2021;120501.

Öblom H, Zhang J, Pimparade M, Speer I, Preis M, Repka M, et al. 3D-printed isoniazid tablets for the treatment and prevention of tuberculosis—personalized dosing and drug release. Aaps Pharmscitech. 2019;20:1–13. Springer.

Kate L, Gokarna V, Borhade V, Prabhu P, Deshpande V, Pathak S, et al. Bioavailability enhancement of atovaquone using hot melt extrusion technology. Eur J Pharm Sci. 2016;86:103–14. Elsevier.

Thiry J, Kok MGM, Collard L, Frère A, Krier F, Fillet M, et al. Bioavailability enhancement of itraconazole-based solid dispersions produced by hot melt extrusion in the framework of the Three Rs rule. Eur J Pharm Sci. 2017;99:1–8. Elsevier.

Zhang J, Feng X, Patil H, Tiwari R V., Repka MA. Coupling 3D printing with hot-melt extrusion to produce controlled-release tablets. Int J Pharm [Internet]. Elsevier B.V.; 2017;519:186–97. Available from: https://doi.org/10.1016/j.ijpharm.2016.12.049

Bandari S, Nyavanandi D, Dumpa N, Repka MA. Coupling hot melt extrusion and fused deposition modeling: critical properties for successful performance. Adv Drug Deliv Rev. 2021;172:52–63. Elsevier. https://doi.org/10.1016/j.addr.2021.02.006.

Huang S, O’Donnell KP, de Vaux SMD, O’Brien J, Stutzman J, Williams RO III. Processing thermally labile drugs by hot-melt extrusion: the lesson with gliclazide. Eur J Pharm Biopharm. 2017;119:56–67. Elsevier.

Henry S, Samaro A, Marchesini FH, Shaqour B, Macedo J, Vanhoorne V, et al. Extrusion-based 3D printing of oral solid dosage forms: material requirements and equipment dependencies. Int J Pharm. 2021;598:120361. Elsevier.

Pereira BC, Isreb A, Forbes RT, Dores F, Habashy R, Petit J-B, et al. ‘Temporary plasticiser’: a novel solution to fabricate 3D printed patient-centred cardiovascular ‘polypill’architectures. Eur J Pharm Biopharm. 2019;135:94–103. Elsevier.

De Jaeghere W, De Beer T, Van Bocxlaer J, Remon JP, Vervaet C. Hot-melt extrusion of polyvinyl alcohol for oral immediate release applications. Int J Pharm. 2015;492:1–9. Elsevier.

Duran C, Subbian V, Giovanetti MT, Simkins JR, Beyette Jr FR. Experimental desktop 3D printing using dual extrusion and water-soluble polyvinyl alcohol. Rapid Prototyp J. 2015;21:528–34. Emerald Group Publishing Limited. https://doi.org/10.1108/RPJ-09-2014-0117.

Skowyra J, Pietrzak K, Alhnan MA. Fabrication of extended-release patient-tailored prednisolone tablets via fused deposition modelling (FDM) 3D printing. Eur J Pharm Sci. 2015;68:11–7. Elsevier.

Ibrahim M, Barnes M, McMillin R, Cook DW, Smith S, Halquist M, et al. 3D printing of metformin HCl PVA tablets by fused deposition modeling: drug loading, tablet design, and dissolution studies. AAPS PharmSciTech. 2019;20:1–11.

Tagami T, Fukushige K, Ogawa E, Hayashi N, Ozeki T. 3D printing factors important for the fabrication of polyvinylalcohol filament-based tablets. Biol Pharm Bull. 2017;40:357–64. The Pharmaceutical Society of Japan.

Tagami T, Kuwata E, Sakai N, Ozeki T. Drug incorporation into polymer filament using simple soaking method for tablet preparation using fused deposition modeling. Biol Pharm Bull. 2019;42:1753–60. The Pharmaceutical Society of Japan.

Tagami T, Nagata N, Hayashi N, Ogawa E, Fukushige K, Sakai N, et al. Defined drug release from 3D-printed composite tablets consisting of drug-loaded polyvinylalcohol and a water-soluble or water-insoluble polymer filler. Int J Pharm. 2018;543:361–7. Elsevier.

Palekar S, Kumar P, Mishra SM, Kipping T, Patel K. Application of 3D printing technology and quality by design approach for development of age-appropriate pediatric formulation of baclofen. Int J Pharm [Internet]. Elsevier; 2019;556:106–16. Available from: https://doi.org/10.1016/j.ijpharm.2018.11.062

Nukala PK, Palekar S, Patki M, Patel K. Abuse deterrent immediate release egg-shaped tablet ( egglets ) using 3D printing technology : quality by design to optimize drug release and extraction. aAPS PharmSciTech; 2019.

Brough C, Miller DA, Keen JM, Kucera SA, Lubda D, Williams RO. Use of polyvinyl alcohol as a solubility-enhancing polymer for poorly water soluble drug delivery (part 1). AAPS PharmSciTech. 2016;17:167–79. Springer.

Xu X, Zhao J, Wang M, Wang L, Yang J. 3D printed polyvinyl alcohol tablets with multiple release profiles. Sci Rep. 2019;9:12487. Nature Publishing Group UK London.

Wei C, Solanki NG, Vasoya JM, Shah AV, Serajuddin ATM. Development of 3D printed tablets by fused deposition modeling using polyvinyl alcohol as polymeric matrix for rapid drug release. J Pharm Sci. 2020;109:1558–72. Elsevier.

Macedo J, Marques R, Vervaet C, Pinto JF. Production of bi-compartmental tablets by FDM 3D printing for the withdrawal of diazepam. Pharmaceutics. 2023;15:538. MDPI.

Uboldi M, Chiappa A, Pertile M, Piazza A, Tagliabue S, Foppoli A, et al. Investigation on the use of fused deposition modeling for the production of IR dosage forms containing Timapiprant. Int J Pharm X. 2023;5:100152. Elsevier.

Gkartzou E, Koumoulos EP, Charitidis CA. Production and 3D printing processing of bio-based thermoplastic filament. Manuf Rev. 2017;4:1. EDP Sciences.

Bogaert J, Coszach P. Poly (lactic acids): a potential solution to plastic waste dilemma. Macromol Symp. WILEY‐VCH Verlag Weinheim; 2000. p. 287–303.

Platt D. Biodegradable polymers: market report [Internet]. 2006. Available from: http://books.google.com/books?hl=en&lr=&id=Jtt2MFkYiP0C&oi=fnd&pg=PA1941&dq=Biodegradable+Polymers+Market+Report&ots=NDKXR5Fyb6&sig=Z2U9bQLrzMsLr9qAj0bcfMhvGyE.

Zhang L, Lv S, Sun C, Wan L, Tan H, Zhang Y. Effect of MAH-g-PLA on the properties of wood fiber/polylactic acid composites. Polymers (Basel). 2017;9:591. Multidisciplinary Digital Publishing Institute.

Nampoothiri KM, Nair NR, John RP. An overview of the recent developments in polylactide (PLA) research. Bioresour Technol. 2010;101:8493–501. Elsevier.

Kmetty Á, Litauszki K, Réti D. Characterization of different chemical blowing agents and their applicability to produce poly (lactic acid) foams by extrusion. Appl Sci. 2018;8:1960. Multidisciplinary Digital Publishing Institute.

Csenge T, Kovács KN. Characterization of short fiber-reinforced polylactic acid composites produced with Fused Filament Fabrication (FFF). IOP Conf Ser Mater Sci Eng. 2020;903:12031. IOP Publishing. https://doi.org/10.1088/1757-899X/903/1/012031.

Lendvai L, Brenn D. Mechanical, morphological and thermal characterization of compatibilized poly (lactic acid)/thermoplastic starch blends. Acta Tech Jaurinensis. 2020;13:1–13.

Lendvai L, Fekete I. Preparation and characterization of poly (lactic acid)/boehmite alumina composites for additive manufacturing. IOP Conf Ser Mater Sci Eng. 2020;903:012057. IOP Publishing. https://doi.org/10.1088/1757-899X/903/1/012057.

Tee YB, Talib RA, Abdan K, Chin NL, Basha RK, Yunos KFM. Toughening poly (lactic acid) and aiding the melt-compounding with bio-sourced plasticizers. Agric Agric Sci Procedia. 2014;2:289–95. Elsevier.

Lan X, Li X, Liu Z, He Z, Yang W, Yang M. Composition, morphology and properties of poly (lactic acid) and poly (butylene succinate) copolymer system via coupling reaction. J Macromol Sci Part A. 2013;50:861–70. Taylor & Francis.

Alias NF, Ismail H. An overview of toughening polylactic acid by an elastomer. Polym Technol Mater. 2019;58:1399–422. Taylor & Francis.

Jo W, Kwon O-C, Moon M-W. Investigation of influence of heat treatment on mechanical strength of FDM printed 3D objects. Rapid Prototyp J. 2018;24:637–44. Emerald Publishing Limited. https://doi.org/10.1108/RPJ-06-2017-0131.

Rajpurohit SR, Dave HK. Effect of process parameters on tensile strength of FDM printed PLA part. Rapid Prototyp J. 2018;24:1317–24. Emerald Publishing Limited. https://doi.org/10.1108/RPJ-06-2017-0134.

Malakar TK, Chaudhari VS, Dwivedy SK, Murty US, Banerjee S. 3D Printed housing devices for segregated compartmental delivery of oral fixed-dose anti-tubercular drugs adopting print and fill strategy. 3D Print Addit Manuf. 2022;9:535–46. Mary Ann Liebert, Inc. https://doi.org/10.1089/3dp.2021.0037.

Zhao X, Wei W, Niu R, Li Q, Hu C, Jiang S. 3D printed intragastric floating and sustained-release tablets with air chambers. J Pharm Sci. 2022;111:116–23. Elsevier.

Charoenying T, Chaksmithanont P, Panomsuk S, Nattapulwat N, Plianwong S, Patrojanasophon P, et al. Fabrication of a novel high-density three-dimensional (3D)-printed device for domperidone tablets. Thai Bull Pharm Sci. 2023;18:97–105.

Thanawuth K, Limmatvapirat S, Rojviriya C, Sriamornsak P. Controlled release of felodipine from 3D-printed tablets with constant surface area: influence of surface geometry. Pharmaceutics. 2023;15:467. MDPI.

Awasthi R, Manchanda S, Das P, Velu V, Malipeddi H, Pabreja K, et al. Poly (vinylpyrrolidone). Eng Biomater Drug Deliv Syst. 2018:255–72. Elsevier. https://doi.org/10.1016/B978-0-08-101750-0.00009-X.

Wilts EM, Ma D, Bai Y, Williams CB, Long TE. Comparison of linear and 4-arm star poly (vinyl pyrrolidone) for aqueous binder jetting additive manufacturing of personalized dosage tablets. ACS Appl Mater Interfaces. 2019;11:23938–47. ACS Publications.

Khaled SA, Alexander MR, Irvine DJ, Wildman RD, Wallace MJ, Sharpe S, et al. Extrusion 3D printing of paracetamol tablets from a single formulation with tunable release profiles through control of tablet geometry. AAPS PharmSciTech. 2018;19:3403–13. Springer.

Okwuosa TC, Stefaniak D, Arafat B, Isreb A, Wan K-W, Alhnan MA. A lower temperature FDM 3D printing for the manufacture of patient-specific immediate release tablets. Pharm Res. 2016;33:2704–12. Springer.

Kempin W, Domsta V, Grathoff G, Brecht I, Semmling B, Tillmann S, et al. Immediate release 3D-printed tablets produced via fused deposition modeling of a thermo-sensitive drug. Pharm Res. 2018;35:1–12. Springer.

Franco P, De Marco I. The use of poly (N-vinyl pyrrolidone) in the delivery of drugs: a review. Polymers (Basel). 2020;12:1114. Multidisciplinary Digital Publishing Institute.

Rowe RC, Sheskey P, Quinn M. Handbook of pharmaceutical excipients. Libros Digitales-Pharmaceutical Press. 2009.

Zema L, Loreti G, Melocchi A, Maroni A, Palugan L, Gazzaniga A. Gastroresistant capsular device prepared by injection molding. Int J Pharm. 2013;440:264–72. Elsevier.

Pereira GG, Figueiredo S, Fernandes AI, Pinto JF. Polymer selection for hot-melt extrusion coupled to fused deposition modelling in pharmaceutics. Pharmaceutics. 2020;12:1–63.

Chavan RB, Rathi S, Jyothi VGSS, Shastri NR. Cellulose based polymers in development of amorphous solid dispersions. Asian J Pharm Sci. 2019;14:248–64. Elsevier.

Edgar KJ, Buchanan CM, Debenham JS, Rundquist PA, Seiler BD, Shelton MC, et al. Advances in cellulose ester performance and application. Prog Polym Sci. 2001;26:1605–88. Elsevier.

Giri BR, Poudel S, Kim DW. Cellulose and its derivatives for application in 3D printing of pharmaceuticals. J Pharm Investig. Springer; 2020;1–22.

Zhang J, Xu P, Vo AQ, Bandari S, Yang F, Durig T, et al. Development and evaluation of pharmaceutical 3D printability for hot melt extruded cellulose-based filaments. J Drug Deliv Sci Technol. 2019;52:292–302. Elsevier. https://doi.org/10.1016/j.jddst.2019.04.043.

Patere SN, Kapadia CJ, Nagarsenker MS. Influence of formulation factors and compression force on release profile of sustained release Metoprolol tablets using Compritol® 888ATO as lipid excipient. Indian J Pharm Sci. 2015;77:620. Wolters Kluwer--Medknow Publications.

Lee PI, Peppas NA. Prediction of polymer dissolution in swellable controlled-release systems. J Control Release. 1987;6:207–15. Elsevier.

Ghosal K, Chakrabarty S, Nanda A. Hydroxypropyl methylcellulose in drug delivery. Der Pharmacia Sinica. 2011;2:152–68. Pelagia Research Library.

Bennett RC, Keen JM, Bi Y, Porter S, Dürig T, McGinity JW. Investigation of the interactions of enteric and hydrophilic polymers to enhance dissolution of griseofulvin following hot melt extrusion processing. J Pharm Pharmacol. 2015;67:918–38. Oxford University Press.

Beck RCR, Chaves PS, Goyanes A, Vukosavljevic B, Buanz A, Windbergs M, et al. 3D printed tablets loaded with polymeric nanocapsules: An innovative approach to produce customized drug delivery systems. Int J Pharm. 2017;528:268–79. Elsevier.

Ooasaka K, Tokuda M, Furukawa N. Intra-gastric triacetin alters upper gastrointestinal motility in conscious dogs. World J Gastroenterol WJG. 2014;20:1054. Baishideng Publishing Group Inc.

Khizer Z, Akram MR, Sarfraz RM, Nirwan JS, Farhaj S, Yousaf M, et al. Plasticiser-free 3D printed hydrophilic matrices: quantitative 3D surface texture, mechanical, swelling, erosion, drug release and pharmacokinetic studies. Polymers (Basel). 2019;11:1095. Multidisciplinary Digital Publishing Institute.

Yang HS, Kim DW. Fabrication of gastro-floating famotidine tablets: hydroxypropyl methylcellulose-based semisolid extrusion 3D printing. Pharmaceutics. MDPI; 2023;15:316.

Johnson JL, Holinej J, Williams MD. Influence of ionic strength on matrix integrity and drug release from hydroxypropyl cellulose compacts. Int J Pharm. 1993;90:151–9. Elsevier.

Bercea M, Navard P. Viscosity of hydroxypropyl cellulose solutions in non-entangled and entangled states. Cellul Chem Technol. 2019. HAL Open access.

Arafat B, Wojsz M, Isreb A, Forbes RT, Isreb M, Ahmed W, et al. Tablet fragmentation without a disintegrant: a novel design approach for accelerating disintegration and drug release from 3D printed cellulosic tablets. Eur J Pharm Sci. 2018;118:191–9.

Melocchi A, Parietti F, Loreti G, Maroni A, Gazzaniga A, Zema L. 3D printing by fused deposition modeling (FDM) of a swellable/erodible capsular device for oral pulsatile release of drugs. J Drug Deliv Sci Technol. 2015;30:360–7.

Oladeji SA, Dadou SM, Zhao M, Li S, Jones DS, Andrews GP. The development and optimisation of gastro-retentive floating tablets using fused deposition modelling 3D printing. J Pharm Pharmacol. 2022;74:1450–66. Oxford University Press UK.

Erkoç T, Sevgili LM, Çavuş S. Hydroxypropyl cellulose/polyvinylpyrrolidone matrix tablets containing ibuprofen: infiltration, erosion and drug release characteristics. ChemistrySelect. 2022;7:e202202180. Wiley Online Library.

Badawy SIF, Narang AS, LaMarche KR, Subramanian GA, Varia SA. Handbook of pharmaceutical wet granulation. Academic Press Amsterdam. 2019:173–202. The Netherlands.

Gómez-Carracedo A, Alvarez-Lorenzo C, Gómez-Amoza JL, Concheiro A. Chemical structure and glass transition temperature of non-ionic cellulose ethers. J Therm Anal Calorim. 2003;73:587–96. Springer.

Deng W, Majumdar S, Singh A, Shah S, Mohammed NN, Jo S, et al. Stabilization of fenofibrate in low molecular weight hydroxypropylcellulose matrices produced by hot-melt extrusion. Drug Dev Ind Pharm. 2013;39:290–8. Taylor & Francis.

Yang Y, Wang H, Li H, Ou Z, Yang G. 3D printed tablets with internal scaffold structure using ethyl cellulose to achieve sustained ibuprofen release. Eur J Pharm Sci. 2018;115:11–8. Elsevier.

Chandran S, Asghar LFA, Mantha N. Design and evaluation of ethyl cellulose based matrix tablets of ibuprofen with pH modulated release kinetics. Indian J Pharm Sci. 2008;70:596. Wolters Kluwer--Medknow Publications.

Vaz VM, Kumar L. 3D printing as a promising tool in personalized medicine. AAPS PharmSciTech. 2021;22:1–20. Springer.

Tabriz AG, Scoutaris N, Gong Y, Hui H-W, Kumar S, Douroumis D. Investigation on hot melt extrusion and prediction on 3D printability of pharmaceutical grade polymers. Int J Pharm. 2021;604:120755. Elsevier. https://doi.org/10.1016/j.ijpharm.2021.120755.

Bates-Green K, Howie T. Materials for 3D printing by fused deposition. Edmonds Community Coll. 2017:1–21. Edmonds Community College.

Fuenmayor E, Forde M, Healy A V, Devine DM, Lyons JG, McConville C, et al. Material considerations for fused-filament fabrication of solid dosage forms. Pharmaceutics. 2018;10:44. Multidisciplinary Digital Publishing Institute. https://doi.org/10.3390/pharmaceutics10020044.

Kolter K, Karl M, Gryczke A. Introduction to solid dispersions. Hot-Melt Extrus. with BASF Pharma Polym. 2012:9–18.

Aho J, Boetker JP, Baldursdottir S, Rantanen J. Rheology as a tool for evaluation of melt processability of innovative dosage forms. Int J Pharm. 2015;494:623–42. Elsevier.

Solanki NG, Tahsin M, Shah AV, Serajuddin ATM. Formulation of 3D printed tablet for rapid drug release by fused deposition modeling: screening polymers for drug release, drug-polymer miscibility and printability. J Pharm Sci. 2018;107:390–401. Elsevier.

Shenoy AV, Saini DR. Melt flow index: more than just a quality control rheological parameter. Part I. Adv Polym Technol. 1986;6:1–58. Wiley Subscription Services, Inc., A Wiley Company New York.

Wang S, Capoen L, D’hooge DR, Cardon L. Can the melt flow index be used to predict the success of fused deposition modelling of commercial poly (lactic acid) filaments into 3D printed materials? Plast Rubber Compos. Taylor & Francis; 2018;47:9–16.

Arafat B, Qinna N, Cieszynska M, Forbes RT, Alhnan MA. Tailored on demand anti-coagulant dosing: an in vitro and in vivo evaluation of 3D printed purpose-designed oral dosage forms. Eur J Pharm Biopharm. 2018;128:282–9. Elsevier.

Torres-Martínez EJ, Cornejo Bravo JM, Serrano Medina A, Pérez González GL, Villarreal Gómez LJ. A summary of electrospun nanofibers as drug delivery system: drugs loaded and biopolymers used as matrices. Curr Drug Deliv. 2018;15:1360–74. Bentham Science Publishers.

Bhatt U, Malakar TK, Murty US, Banerjee S. 3D printing of immediate-release tablets containing olanzapine by filaments extrusion. Drug Dev Ind Pharm. 2021;47:1200–8. Taylor & Francis Online. https://doi.org/10.1080/03639045.2021.1879833.

Bharti C, Nagaich U, Pal AK, Gulati N. Mesoporous silica nanoparticles in target drug delivery system: a review. Int J Pharm Investig. 2015;5:124. Wolters Kluwer--Medknow Publications.

O Abioye A, Tangyie Chi G, T Kola-Mustapha A, Ruparelia K, Beresford K, Arroo R. Polymer-drug nanoconjugate–an innovative nanomedicine: challenges and recent advancements in rational formulation design for effective delivery of poorly soluble drugs. Pharm Nanotechnol. Bentham Science Publishers; 2016;4:38–79.

Miyamoto T, Long M, Donkai N. Preparation of new types of temperature‐responsive cellulose derivatives. Macromol Symp. 1995;99:141–7. Wiley Online Library. https://doi.org/10.1002/masy.19950990115.

Talik P, Hubicka U. The DSC approach to study non-freezing water contents of hydrated hydroxypropylcellulose (HPC). J Therm Anal Calorim Springer. 2018;132:445–51. Springer).

Gao H, Yang R, He J, Yang L. Rheological behaviors of PVA/H2O solutions of high-polymer concentration. J Appl Polym Sci. 2010;116:1459–66. Wiley Online Library.

Bilhim T, Pisco JM, Duarte M, Oliveira AG. Polyvinyl alcohol particle size for uterine artery embolization: a prospective randomized study of initial use of 350–500μm particles versus initial use of 500–700μm particles. J Vasc Interv Radiol. 2011;22:21–7.

Fang Q, Hanna MA. Rheological properties of amorphous and semicrystalline polylactic acid polymers. Ind Crops Prod. 1999;10:47–53. Elsevier.

Mineshita T, Watanabe T, Ono S. The flow properties of polyvinylpyrrolidone solutions. Bull Chem Soc Jpn. 1967;40:2217–23. The Chemical Society of Japan.

Batra A, Yang F, Kogan M, Sosnowik A, Usher C, Oldham EW, et al. Comparison of hydroxypropylcellulose and hot-melt extrudable hypromellose in twin-screw melt granulation of metformin hydrochloride: effect of rheological properties of polymer on melt granulation and granule properties. Macromol. 2021;2:1–19. MDPI.

Oh CM, Heng PWS, Chan LW. A study on the impact of hydroxypropyl methylcellulose on the viscosity of PEG melt suspensions using surface plots and principal component analysis. AAPS PharmSciTech. 2015;16:466–77. Springer.

Rekhi GS, Jambhekar SS. Ethylcellulose - a polymer review. Drug Dev Ind Pharm. 1995;21:61–77.

Seng CT, A/l Eh Noum SY, A/l Sivanesan SK, Yu LJ. Reduction of hygroscopicity of PLA filament for 3D printing by introducing nano silica as filler. AIP Conf Proc. 2020;2233:020024-1-12. AIP Publishing. https://doi.org/10.1063/5.0001927.

Jamróz W, Kurek M, Szafraniec-Szczęsny J, Czech A, Gawlak K, Knapik-Kowalczuk J, et al. Speed it up, slow it down… An issue of bicalutamide release from 3D printed tablets. Eur J Pharm Sci. Elsevier; 2020;143:105169.

Tan DK, Maniruzzaman M, Nokhodchi A. Development and optimisation of novel polymeric compositions for sustained release theophylline caplets (PrintCap) via FDM 3D printing. Polymers (Basel). 2020;12:27. Multidisciplinary Digital Publishing Institute.

Chen D, Xu X-Y, Li R, Zang G-A, Zhang Y, Wang M-R, et al. Preparation and in vitro evaluation of FDM 3D-printed ellipsoid-shaped gastric floating tablets with low infill percentages. AAPS PharmSciTech. 2020;21:1–13. Springer.

Ilyés K, Kovács NK, Balogh A, Borbás E, Farkas B, Casian T, et al. The applicability of pharmaceutical polymeric blends for the fused deposition modelling (FDM) 3D technique: material considerations–printability–process modulation, with consecutive effects on in vitro release, stability and degradation. Eur J Pharm Sci. 2019;129:110–23.

Fu J, Yin H, Yu X, Xie C, Jiang H, Jin Y, et al. Combination of 3D printing technologies and compressed tablets for preparation of riboflavin floating tablet-in-device (TiD) systems. Int J Pharm [Internet]. Elsevier B.V.; 2018;549:370–9. Available from: https://doi.org/10.1016/j.ijpharm.2018.08.011.

Gioumouxouzis CI, Baklavaridis A, Katsamenis OL, Markopoulou CK, Bouropoulos N, Tzetzis D, et al. A 3D printed bilayer oral solid dosage form combining metformin for prolonged and glimepiride for immediate drug delivery. Eur J Pharm Sci. 2018;120:40–52. Elsevier.

Sadia M, Isreb A, Abbadi I, Isreb M, Aziz D, Selo A, et al. From ‘fixed dose combinations’ to ‘a dynamic dose combiner’: 3D printed bi-layer antihypertensive tablets. Eur J Pharm Sci. 2018;123:484–94. Elsevier.

Jamróz W, Kurek M, Czech A, Szafraniec J, Gawlak K, Jachowicz R. 3D printing of tablets containing amorphous aripiprazole by filaments co-extrusion. Eur J Pharm Biopharm. 2018;131:44–7. Elsevier.

Kollamaram G, Croker DM, Walker GM, Goyanes A, Basit AW, Gaisford S. Low temperature fused deposition modeling (FDM) 3D printing of thermolabile drugs. Int J Pharm [Internet]. 2018;545:144–52. Available from: https://doi.org/10.1016/j.ijpharm.2018.04.055

Genina N, Boetker JP, Colombo S, Harmankaya N, Rantanen J, Bohr A. Anti-tuberculosis drug combination for controlled oral delivery using 3D printed compartmental dosage forms: from drug product design to in vivo testing. J Control Release. 2017;268:40–8. Elsevier.

Gioumouxouzis CI, Katsamenis OL, Bouropoulos N, Fatouros DG. 3D printed oral solid dosage forms containing hydrochlorothiazide for controlled drug delivery. J Drug Deliv Sci Technol. 2017;40:164–71. Elsevier.

Boetker J, Water JJ, Aho J, Arnfast L, Bohr A, Rantanen J. Modifying release characteristics from 3D printed drug-eluting products. Eur J Pharm Sci [Internet]. Elsevier B.V.; 2016;90:47–52. Available from: https://doi.org/10.1016/j.ejps.2016.03.013.

Goyanes A, Chang H, Sedough D, Hatton GB, Wang J, Buanz A, et al. Fabrication of controlled-release budesonide tablets via desktop (FDM) 3D printing. Int J Pharm. 2015;496:414–20. Elsevier.

Melocchi A, Parietti F, Casati F, Maroni A, Gazzaniga A, Zema L. 3D printing by fused deposition modeling of capsular devices for oral pulsatile release based on swellable/erodible polymers. J Drug Deliv Sci Technol. 2015;30:360–7.

Kimura S, Ishikawa T, Iwao Y, Itai S, Kondo H. Fabrication of zero-order sustained-release floating tablets via fused depositing modeling 3D printer. Chem Pharm Bull. 2019;67:992–9.

Roulon S, Soulairol I, Cazes M, Lemierre L, Payre N, Delbreilh L, et al. D-sorbitol physical properties effects on filaments used by 3d printing process for personalized medicine. Molecules. 2021;26:1–21.

Funk NL, Fantaus S, Beck RCR. Immediate release 3D printed oral dosage forms: how different polymers have been explored to reach suitable drug release behaviour. Int J Pharm. 2022;625:122066. Elsevier. https://doi.org/10.1016/j.ijpharm.2022.122066.

Ayyoubi S, Cerda JR, Fernández-García R, Knief P, Lalatsa A, Healy AM, et al. 3D printed spherical mini-tablets: geometry versus composition effects in controlling dissolution from personalised solid dosage forms. Int J Pharm. 2021;597:120336. Elsevier. https://doi.org/10.1016/j.ijpharm.2021.120336.

Gorkem Buyukgoz G, Kossor CG, Ji S, Guvendiren M, Davé RN. Dose titration of solid dosage forms via FDM 3D-printed mini-tablets. Pharmaceutics. 2022;14:2305.

Raje V, Palekar S, Banella S, Patel K. Tunable drug release from fused deposition modelling (FDM) 3D-printed tablets fabricated using a novel extrudable polymer. Pharmaceutics. 2022;14:2192. MDPI. https://doi.org/10.3390/pharmaceutics14102192.

Khaled SA, Burley JC, Alexander MR, Yang J, Roberts CJ. 3D printing of tablets containing multiple drugs with defined release profiles. Int J Pharm. 2015;494:643–50.

Sadia M, Sośnicka A, Arafat B, Isreb A, Ahmed W, Kelarakis A, et al. Adaptation of pharmaceutical excipients to FDM 3D printing for the fabrication of patient-tailored immediate release tablets. Int J Pharm [Internet]. Elsevier B.V.; 2016;513:659–68. Available from: https://doi.org/10.1016/j.ijpharm.2016.09.050.

Deshkar S, Rathi M, Zambad S, Gandhi K. Hot melt extrusion and its application in 3D printing of pharmaceuticals. Curr Drug Deliv. 2021;18:387–407. Bentham Science Publishers.

Long J, Gholizadeh H, Lu J, Bunt C, Seyfoddin A. Application of fused deposition modelling (FDM) method of 3D printing in drug delivery. Curr Pharm Des. 2017;23:433–9. Bentham Science Publishers.

Funding

This research was funded by Malaysian Ministry of Higher Education (MOHE) Prototype Research Grant Scheme, grant number PRGS19-005–0049 and ASEAN-India International Collaborative Research Project sponsored by Science & Engineering Research Board (SERB), DST, Gov. of India, New Delhi, grant number IMRC/AISTDF/CRD/2019/000147.

Author information

Authors and Affiliations

Contributions

Conceptualization, AA.D. and NF.L.; writing-original draft preparation, AA.D. and NF.L.; writing-review and editing, S.S., M.K., M.A, R.E. and A.B.; supervision, AA.D. and A.B.; project administration, A.B. and AA.D.; funding acquisition, AA.D. and A.B. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Doolaanea, A., Latif, N., Singh, S. et al. A Review on Physicochemical Properties of Polymers Used as Filaments in 3D-Printed Tablets. AAPS PharmSciTech 24, 116 (2023). https://doi.org/10.1208/s12249-023-02570-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-023-02570-3