Abstract

Microcrystalline cellulose (MCC) of different grades from different manufacturers differ in particulate and powder properties significantly. The choice of MCC is important to the development of a tablet formulation with satisfactory quality. In this study, the effects of five different MCCs (KG 802, Pharmacel 102, MC 302, M 200, and PH 112) that had different compactibility and tablet disintegration on the tablet quality of two different natural plant products (NPPs) were evaluated systematically, including Crataegi Folium ethanol extract (CF-E) and Sarcandrae Herba water extract (SH-W). The result of D-optimal mixture designs demonstrated that KG 802 showed the best ability to improve compression properties and tensile strength, followed by Pharmacel 102, MC 302, and M 200. PH 112 did the weakest. However, MCCs of different grades had no different influence on the disintegration of NPP tablets. Similar results were found in the experiments of the two different NPP powders, suggesting the generalization of the finding. Moreover, KG 802-containing CF-E formulations showed the largest optimum region size, that is, the lowest production risk. The design space sizes of SH-W were hardly sensitive to the change of MCCs, due to the better tabletability. In conclusion, the properties of MCCs could transfer to the high NPP loading (70%) formulations, leading to the variations on the compression properties and tablet quality. The poorer the tabletability of NPP, the more obvious the variation. The result is promising for the use of MCC and the manufacturing of high drug-loading NPP tablets by direct compression.

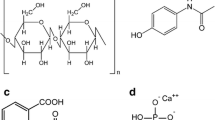

Graphical Abstract

Similar content being viewed by others

Data Availability

Data will be made available on request.

Abbreviations

- MCC:

-

Microcrystalline cellulose

- NPP:

-

Natural plant product

- CF-E:

-

Crataegi Folium Ethanol extract

- SH-W:

-

Sarcandrae Herba Water extract

- FDA:

-

Food and Drug Administration

- DC:

-

Direct compression

- TS, σ:

-

Tensile strength

- DT:

-

Disintegration time

- ρ b :

-

Bulk density

- ρ t :

-

Tapped density

- ρ true :

-

True density

- ε:

-

Porosity

- D50:

-

Median particle size

- LAC:

-

Spray-dried monohydrate lactose

- DCPA:

-

Dicalcium phosphate anhydrate

- CCS:

-

Croscarmellose sodium

- MgSt:

-

Magnesium stearate

- Py:

-

Yield pressure

- R2 :

-

Coefficient of determination

- Eq:

-

Equation

References

Jugran AK, Rawat S, Devkota HP, Bhatt ID, Rawal RS. Diabetes and plant-derived natural products: from ethnopharmacological approaches to their potential for modern drug discovery and development. Phytother Res. 2021;35(1):223–45. https://doi.org/10.1002/ptr.6821.

Xiong ZW, Yang B, Zhao YX, Ning RX, Wang B, Lu M, et al. A new direct compression mechanism of structural transition in Poria cocos extract composite particles. Int J Pharm. 2022;623:121913. https://doi.org/10.1016/j.ijpharm.2022.121913.

Zhao H, Zhao L, Wu F, Shen L. Clinical research on traditional Chinese medicine treatment for bacterial vaginosis. Phytother Res. 2021;35(9):4943–56. https://doi.org/10.1002/ptr.7123.

Chi X, Wang S, Baloch Z, Zhang H, Li X, Zhang Z, et al. Research progress on classical traditional Chinese medicine formula Lily Bulb and Rehmannia Decoction in the treatment of depression. Biomed Pharmacother. 2019;112:108616. https://doi.org/10.1016/j.biopha.2019.108616.

CDER: Novel Drug Approvals for 2019. https://www.fda.gov/drugs/new-drugs-fda-cders-new-molecular-entities-and-new-therapeutic-biological-products/novel-drug-approvals-2019 (2019). Accessed July 2022.

CDER: Novel Drug Approvals for 2020. https://www.fda.gov/drugs/new-drugs-fda-cders-new-molecular-entities-and-new-therapeutic-biological-products/novel-drug-approvals-2020 (2020). Accessed July 2022.

CDER: Novel Drug Approvals for 2021. https://www.fda.gov/drugs/new-drugs-fda-cders-new-molecular-entities-and-new-therapeutic-biological-products/novel-drug-approvals-2021 (2021). Accessed July 2022.

Zhang Y, Li J, Gao Y, Wu F, Hong Y, Shen L, et al. Improvements on multiple direct compaction properties of three powders prepared from Puerariae Lobatae Radix using surface and texture modification: Comparison of microcrystalline cellulose and two nano-silicas. Int J Pharm. 2022;622:121837. https://doi.org/10.1016/j.ijpharm.2022.121837.

Li Z, Wu F, Zhao LJ, Lin X, Shen L, Feng Y. Evaluation of fundamental and functional properties of natural plant product powders for direct compaction based on multivariate statistical analysis. Adv Powder Technol. 2018;29(11):2881–94. https://doi.org/10.1016/j.apt.2018.08.009.

Yu YT, Zhao LJ, Lin X, Wang YJ, Du RF, Feng Y. Research on the powder classification and the key parameters affecting tablet qualities for direct compaction based on powder functional properties. Adv Powder Technol. 2021;32(2):565–81. https://doi.org/10.1016/j.apt.2021.01.002.

Zhao H, Zhao L, Lin X, Shen L. An update on microcrystalline cellulose in direct compression: Functionality, critical material attributes, and co-processed excipients. Carbohydr Polym. 2022;278:118968. https://doi.org/10.1016/j.carbpol.2021.118968.

Thoorens G, Krier F, Leclercq B, Carlin B, Evrard B. Microcrystalline cellulose, a direct compression binder in a quality by design environment–a review. Int J Pharm. 2014;473(1–2):64–72. https://doi.org/10.1016/j.ijpharm.2014.06.055.

Li J, Wang Z, Xiu H, Zhao X, Ma F, Liu L, et al. Correlation between the powder characteristics and particle morphology of microcrystalline cellulose (MCC) and its tablet application performance. Powder Technology. 2022;399:117194. https://doi.org/10.1016/j.powtec.2022.117194.

Wang C, Sun CC. The efficient development of a sildenafil orally disintegrating tablet using a material sparing and expedited approach. Int J Pharm. 2020;589:119816. https://doi.org/10.1016/j.ijpharm.2020.119816.

Hsein H, Garrait G, Tamani F, Beyssac E, Hoffart V. Denatured whey protein powder as a new matrix excipient: design and evaluation of mucoadhesive tablets for sustained drug release applications. Pharm Res. 2017;34(2):365–77. https://doi.org/10.1007/s11095-016-2067-1.

Nakamura S, Nakagawa M, Tanaka C, Yuasa H, Sakamoto T. Utility of microcrystalline cellulose to prevent drug segregation in direct powder compression. J Drug Delivery Sci Technol. 2019;52:386–92. https://doi.org/10.1016/j.jddst.2019.05.017.

Nofrerias I, Nardi A, Suñé-Pou M, Suñé-Negre JM, García-Montoya E, Pérez-Lozano P, et al. Comparison between microcrystalline celluloses of different grades made by four manufacturers using the SeDeM diagram expert system as a pharmaceutical characterization tool. Powder Technol. 2019;342:780–8. https://doi.org/10.1016/j.powtec.2018.10.048.

Thoorens G, Krier F, Rozet E, Carlin B, Evrard B. Understanding the impact of microcrystalline cellulose physicochemical properties on tabletability. Int J Pharm. 2015;490(1–2):47–54. https://doi.org/10.1016/j.ijpharm.2015.05.026.

Queiroz ALP, Wood B, Faisal W, Farag F, Garvie-Cook H, Glennon B, et al. Application of percolation threshold to disintegration and dissolution of ibuprofen tablets with different microcrystalline cellulose grades. Int J Pharm. 2020;589:119838. https://doi.org/10.1016/j.ijpharm.2020.119838.

Hayashi Y, Shirotori K, Kosugi A, Kumada S, Leong KH, Okada K, et al. A Precise prediction method for the properties of API-Containing tablets based on data from placebo tablets. Pharmaceutics. 2020;12(7):601. https://doi.org/10.3390/pharmaceutics12070601.

Guo YP, Yang H, Wang YL, Chen XX, Zhang K, Wang YL, et al. Determination of flavonoids compounds of three species and different harvesting periods in Crataegi folium based on LC-MS/MS. Molecules. 2021;26(6). https://doi.org/10.3390/molecules26061602.

Dong P, Pan L, Zhang X, Zhang W, Wang X, Jiang M, et al. Hawthorn (Crataegus pinnatifida Bunge) leave flavonoids attenuate atherosclerosis development in apoE knock-out mice. J Ethnopharmacol. 2017;198:479–88. https://doi.org/10.1016/j.jep.2017.01.040.

Wang H, Wang H, Zhang J, Luo J, Peng C, Tong X, et al. Molecular mechanism of Crataegi folium and Alisma rhizoma in the treatment of dyslipidemia based on network pharmacology and molecular docking. Evid Based Complement Alternat Med. 2022;2022:4891370. https://doi.org/10.1155/2022/4891370.

Zhu X, Jiang Y, Zheng Q, Zhang A, Shi L, Xia L, et al. Apoptosis of platelets inhibited by herba sarcandrae extract through the mitochondria pathway. Evidence-Based Complement Alternat Med. 2018;2018:1956902. https://doi.org/10.1155/2018/1956902.

Han L, Han Y. Network pharmacology-based study on the active component and mechanism of the anti-gastric-cancer effect of Herba Sarcandrae. J Healthcare Eng. 2021;2021:3001131. https://doi.org/10.1155/2021/3001131.

Yiling J, Qin Z, Aiping Z, Lele C, Lemin X, Meihong L. Flavone from Zhongjiefeng (Herba Sarcandrae Glabrae) inhibits platelet apoptosis in immune-induced bone marrow failure through mitochondrial pathway. J Tradit Chin Med. 2017;37(5):643–9. https://doi.org/10.1016/S0254-6272(17)30318-7.

Al Hagbani T, Altomare C, Salawi A, Nazzal S. D-optimal mixture design: Formulation development, mechanical characterization, and optimization of curcumin chewing gums using oppanol(R) B 12 elastomer as a gum-base. Int J Pharm. 2018;553(1–2):210–9. https://doi.org/10.1016/j.ijpharm.2018.10.047.

Xu GL, Li MH, Lu P. Experimental investigation on flow properties of different biomass and torrefied biomass powders. Biomass Bioenerg. 2019;122:63–75. https://doi.org/10.1016/j.biombioe.2019.01.016.

Zhang Y, Li Y, Wu F, Hong Y, Shen L, Lin X, et al. Texture and surface feature-mediated striking improvements on multiple direct compaction properties of Zingiberis Rhizoma extracted powder by coprocessing with nano-silica. Int J Pharm. 2021;603:120703. https://doi.org/10.1016/j.ijpharm.2021.120703.

Yu Y, Zhao L, Lin X, Wang Y, Feng Y. A model to simultaneously evaluate the compressibility and compactibility of a powder based on the compression ratio. Int J Pharm. 2020;577:119023. https://doi.org/10.1016/j.ijpharm.2020.119023.

Zhao H, Yu Y, Ni N, Zhao L, Lin X, Wang Y, et al. A new parameter for characterization of tablet friability based on a systematical study of five excipients. Int J Pharm. 2022;611:121339. https://doi.org/10.1016/j.ijpharm.2021.121339.

Heckel W. Density-pressure relationships in powder compaction. Trans Metall Soc AIME. 1961;221(4):671–5.

Klevan I, Nordstrom J, Bauer-Brandl A, Alderborn G. On the physical interpretation of the initial bending of a Shapiro-Konopicky-Heckel compression profile. Eur J Pharm Biopharm. 2009;71(2):395–401. https://doi.org/10.1016/j.ejpb.2008.09.014.

Kawakita K, Lüdde K-H. Some considerations on powder compression equations. Powder Technol. 1971;4(2):61–8. https://doi.org/10.1016/0032-5910(71)80001-3.

Zhao J, Burt HM, Miller RA. The Gurnham equation in characterizing the compressibility of pharmaceutical materials. Int J Pharm. 2006;317(2):109–13. https://doi.org/10.1016/j.ijpharm.2006.02.054.

Sun CC. Mechanism of moisture induced variations in true density and compaction properties of microcrystalline cellulose. Int J Pharm. 2008;346(1):93–101. https://doi.org/10.1016/j.ijpharm.2007.06.017.

Berardi A, Bisharat L, Quodbach J, Abdel Rahim S, Perinelli DR, Cespi M. Advancing the understanding of the tablet disintegration phenomenon - an update on recent studies. Int J Pharm. 2021;598:120390. https://doi.org/10.1016/j.ijpharm.2021.120390.

Yin XZ, Maharjan A, Fang LW, Wu L, Zhang L, Shakya S, et al. Cavities spatial distribution confined by microcrystalline cellulose particles determines tablet disintegration patterns. Powder Technol. 2018;339:717–27. https://doi.org/10.1016/j.powtec.2018.08.060.

Iyer RM, Hegde S, Dinunzio J, Singhal D, Malick W. The impact of roller compaction and tablet compression on physicomechanical properties of pharmaceutical excipients. Pharm Dev Technol. 2014;19(5):583–92. https://doi.org/10.3109/10837450.2013.813541.

De Boer AH, Vromans H, Lerk CF, Bolhuis GK, Kussendrager KD, Bosch H. Studies on tableting properties of lactose. Part III. The consolidation behaviour of sieve fractions of crystalline alpha-lactose monohydrate. Pharm Weekbl Sci. 1986;8(2):145–50. https://doi.org/10.1007/BF02086149.

Kawakita K, Tsutsumi Y. A Comparison of equations for powder compression. Bull Chem Soc Jpn. 1966;39(7):1364–8. https://doi.org/10.1246/bcsj.39.1364.

Vreeman G, Sun CC. Mean yield pressure from the in-die Heckel analysis is a reliable plasticity parameter. Int J Pharm X. 2021;3:100094. https://doi.org/10.1016/j.ijpx.2021.100094.

Odeku OA. The Compaction of pharmaceutical powders. Pharmaceutical Reviews. 2007;5(2).

Solomon S, Ziaee A, Giraudeau L, O’Reilly E, Walker G, Albadarin AB. Particle engineering of excipients: a mechanistic investigation into the compaction properties of lignin and [co]-spray dried lignin. Int J Pharm. 2019;563:237–48. https://doi.org/10.1016/j.ijpharm.2019.03.061.

Soundaranathan M, Vivattanaseth P, Walsh E, Pitt K, Johnston B, Markl D. Quantification of swelling characteristics of pharmaceutical particles. Int J Pharm. 2020;590:119903. https://doi.org/10.1016/j.ijpharm.2020.119903.

Bauhuber S, Warnke G, Berardi A. Disintegrant selection in hydrophobic tablet formulations. J Pharm Sci. 2021;110(5):2028–37. https://doi.org/10.1016/j.xphs.2020.11.002.

Alyami H, Dahmash E, Bowen J, Mohammed AR. An investigation into the effects of excipient particle size, blending techniques and processing parameters on the homogeneity and content uniformity of a blend containing low-dose model drug. PLoS One. 2017;12(6):e0178772. https://doi.org/10.1371/journal.pone.0178772.

Bafail R, Rawas-Qalaji M, Rawas-Qalaji M, Aodah A. Effect of the filler grade on the characteristics and the sublingual permeability of atropine sulfate fast disintegrating sublingual tablets. Drug Dev Ind Pharm. 2019;45(10):1617–23. https://doi.org/10.1080/03639045.2019.1648499.

Funding

This work was sponsored by the National Natural Science Foundation of China (82003958); The Natural Science Foundation project of Shanghai (23ZR1463500); National Drug Standard Improvement Project 2022 (2022Y26); The Budgetary project of Shanghai University of Traditional Chinese Medicine (2020LK022).

Author information

Authors and Affiliations

Contributions

Haiyue Zhao: methodology, data curation, writing—original draft, investigation. Chuting Shi: methodology, investigation. Zhenda Liu: software, investigation. Lijie Zhao: conceptualization, methodology, writing—review & editing, supervision, funding acquisition. Lan Shen: conceptualization, writing—review & editing, resources, supervision, funding acquisition.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, H., Shi, C., Liu, Z. et al. Evaluating the Effect of Microcrystalline Cellulose Variations on Tablet Quality of Natural Plant Product Using a Design of Experiment Approach. AAPS PharmSciTech 24, 113 (2023). https://doi.org/10.1208/s12249-023-02556-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-023-02556-1