Abstract

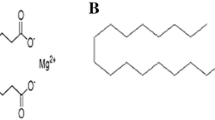

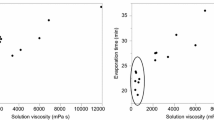

Magnesium stearate (MgSt) is perhaps one of the most frequently used lubricants in tablet formulation due to its superior lubrication capacity, yet it could also negatively affect the critical quality attributes of pharmaceutical products. Therefore, we provided a rather comprehensive evaluation of another two FDA-approved metallic stearates, sodium stearate (NaSt) and calcium stearate (CaSt), as alternative tablet lubricants. The primary objective of the present study is to comparatively evaluate the physicochemical properties and lubrication efficiency of the three metallic stearates. In addition, it was also aimed to specify the most influential factor for ranking and differentiating the lubricity of various lubricants using principal component analysis. Unit ejection force could be used herein as a simple and the most powerful parameter to evaluate the lubrication performance instead of the friction coefficient. The results suggested that CaSt, MgSt, and NaSt had similar impacts on the mechanical strength of tablets. However, CaSt exhibited insufficient lubrication effects as the formulations containing CaSt showed low pressure transmission ratios, high unit ejection forces, and high friction coefficients. In contrast, both MgSt and NaSt displayed satisfactory lubrication efficiency without negatively impacting tabletability. Notably, the lubrication performance of the formulation containing 0.5 wt% NaSt was almost identical to that of the formulation with 1 wt% MgSt, indicating that NaSt had a remarkable lubrication capability probably due to its high specific surface area. In summary, the findings of this investigation should provide practical information and feasible methodologies to readily determine the lubricity and to sensibly select alternative lubricants for pharmaceutical tablet formulations.

Graphical abstract

Similar content being viewed by others

References

Yu S, Adams M, Gururajan B, Reynolds G, Roberts R, Wu C-Y. The effects of lubrication on roll compaction, ribbon milling and tabletting. Chem Eng Sci. 2013;86:9–18.

Park H, Kim J-S, Hong S, Ha E-S, Nie H, Zhou QT, et al. Tableting process-induced solid-state polymorphic transition. Journal of Pharmaceutical Investigation. 2022.

Mosig J, Kleinebudde P. Evaluation of lubrication methods: how to generate a comparable lubrication for dry granules and powder material for tableting processes. Powder Technol. 2014;266:156–66.

Jarosz PJ, Parrott EL. Effect of lubricants on tensile strengths of tablets. Drug Dev Ind Pharm. 1984;10(2):259–73.

Paul S, Sun CC. Lubrication with magnesium stearate increases tablet brittleness. Powder Technol. 2017;309:126–32.

Wang J, Wen H, Desai D. Lubrication in tablet formulations. Eur J Pharm Biopharm. 2010;75(1):1–15.

Kikuta J-I, Kitamori N. Effect of mixing time on the lubricating properties of magnesium stearate and the final characteristics of the compressed tablets. Drug Dev Ind Pharm. 1994;20(3):343–55.

Morin G, Briens L. The effect of lubricants on powder flowability for pharmaceutical application. AAPS PharmSciTech. 2013;14(3):1158–68.

Nie H, Byrn SR, Zhou Q. Stability of pharmaceutical salts in solid oral dosage forms. Drug Dev Ind Pharm. 2017;43(8):1215–28.

Nie H, Byrn SR. Polymorphism and phase transitions. Pharmaceutical Crystals2018. p. 169–221.

Li J, Wu Y. Lubricants in pharmaceutical solid dosage forms. Lubricants. 2014;2(1):21–43.

Nie H, Mo H, Byrn SR. Investigating the physicochemical stability of highly purified darunavir ethanolate extracted from PREZISTA® tablets. AAPS PharmSciTech. 2018;19(5):2407–17.

Nie H, Xu W, Ren J, Taylor LS, Marsac PJ, John CT, et al. Impact of metallic stearates on disproportionation of hydrochloride salts of weak bases in solid-state formulations. Mol Pharm. 2016;13(10):3541–52.

Nie H, Klinzing G, Xu W. A comparative study of applying backscattering and transmission Raman spectroscopy to quantify solid-state form conversion in pharmaceutical tablets. Int J Pharm. 2022;617: 121608.

Nie H, Liu Z, Marks BC, Taylor LS, Byrn SR, Marsac PJ. Analytical approaches to investigate salt disproportionation in tablet matrices by Raman spectroscopy and Raman mapping. J Pharm Biomed Anal. 2016;118:328–37.

Nie H, Xu W, Taylor LS, Marsac PJ, Byrn SR. Crystalline solid dispersion-a strategy to slowdown salt disproportionation in solid state formulations during storage and wet granulation. Int J Pharm. 2017;517(1):203–15.

Démuth B, Farkas A, Balogh A, Bartosiewicz K, Kállai-Szabó B, Bertels J, et al. Lubricant-induced crystallization of itraconazole from tablets made of electrospun amorphous solid dispersion. J Pharm Sci. 2016;105(9):2982–8.

Inactive Ingredient Search for Approved Drug Products [Internet]. 2022.

Daraghmeh N, Rashid I, Al Omari MM, Leharne SA, Chowdhry BZ, Badwan A. Preparation and characterization of a novel co-processed excipient of chitin and crystalline mannitol. AAPS PharmSciTech. 2010;11(4):1558–71.

Fell JT, Newton JM. Determination of tablet strength by the diametral-compression test. 1970;59(5):688–91.

Yu D, Seelam RR, Zhang F, Byrn SR, Hoag SW. Evaluation of tableting performance of poly (ethylene oxide) in abuse-deterrent formulations using compaction simulation studies. J Pharm Sci. 2021;110(7):2789–99.

Hussain M, York P, Timmins P. Effect of commercial and high purity magnesium stearates on in-vitro dissolution of paracetamol DC tablets. Int J Pharm. 1992;78(1–3):203–7.

Almaya A, Aburub A. Effect of particle size on compaction of materials with different deformation mechanisms with and without lubricants. AAPS PharmSciTech. 2008;9(2):414–8.

Dansereau R, Peck GE. The effect of the variability in the physical and chemical properties of magnesium stearate on the properties of compressed tablets. Drug Dev Ind Pharm. 1987;13(6):975–99.

Marwaha S, Rubinstein M. Structure-lubricity evaluation of magnesium stearate. Int J Pharm. 1988;43(3):249–55.

Kato H, Kimura K, Izumi S, Nakamichi K, Danjo K, Sunada H. The effect of magnesium stearate particle size on tablet properties and tableting characteristics of granules prepared with standard formulation. Journal of drug delivery science and technology. 2005;15(6):475–80.

Staniforth JN, Cryer S, Ahmed HA, Davies SP. Aspects of pharmaceutical tribology. Drug Dev Ind Pharm. 1989;15(14–16):2265–94.

Otsuka M, Kaneniwa N, Kawakami K, Umezawa O. Effect of surface characteristics of theophylline anhydrate powder on hygroscopic stability. J Pharm Pharmacol. 1990;42(9):606–10.

Rajala R, Laine E. The effect of moisture on the structure of magnesium stearate. Thermochim Acta. 1995;248:177–88.

Wada Y, Matsubara T. Pseudopolymorphism and lubricating properties of magnesium stearate. Powder Technol. 1994;78(2):109–14.

Jarosz PJ, Parrott EL. Effect of lubricants on tensile strengths of tablets. Drug Dev Ind Pharm. 1984;10(2):259–73.

Park H, Nie H, Dhiman A, Tomar V, Zhou QT. Understanding dynamics of polymorphic conversion during the tableting process using in situ mechanical Raman spectroscopy. Mol Pharm. 2020;17(8):3043–52.

Sun CC. Dependence of ejection force on tableting speed—a compaction simulation study. Powder Technol. 2015;279:123–6.

Nedderman RM. Statics and kinematics of granular materials: Cambridge University Press Cambridge; 1992.

Michrafy A, Kadiri MS, Dodds JA. Wall friction and its effects on the density distribution in the compaction of pharmaceutical excipients. Chem Eng Res Des. 2003;81(8):946–52.

Es-Saheb M. Uniaxial strain rate effects in pharmaceutical powders during cold compaction. J Mater Sci. 1992;27(15):4151–9.

Long W. Radial pressures in powder compaction. Powder Metall. 1960;3(6):73–86.

Hiestand E, Wells J, Peot C, Ochs J. Physical processes of tableting. J Pharm Sci. 1977;66(4):510–9.

Desbois L, Tchoreloff P, Mazel V. Influence of the punch speed on the die wall/powder kinematic friction during tableting. J Pharm Sci. 2019;108(10):3359–65.

Paul S, Sun CC. Systematic evaluation of common lubricants for optimal use in tablet formulation. Eur J Pharm Sci. 2018;117:118–27.

Uzondu B, Leung LY, Mao C, Yang C-Y. A mechanistic study on tablet ejection force and its sensitivity to lubrication for pharmaceutical powders. Int J Pharm. 2018;543(1):234–44.

Acknowledgements

The authors would like to thank Drs. Gerard Klinzing, Meng Li, Jiaying Liu, and Christopher John for providing helpful scientific discussions. Drs. Ting Xu and Jie Ren are specially acknowledged for technical/experimental contributions and data processing. D.Y. is grateful to the visiting scholar opportunity provided by the Center for Materials Science and Engineering at Merck & Co., Inc.

Author information

Authors and Affiliations

Contributions

Dongyue Yu: Methodology, formal analysis, writing — original draft.

Haichen Nie: Conceptualization, methodology, formal analysis, investigation, resources, visualization, project administration, writing — review and editing, visualization.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yu, D., Nie, H. Evaluation of Alternative Metallic Stearates as Lubricants in Pharmaceutical Tablet Formulation. AAPS PharmSciTech 23, 200 (2022). https://doi.org/10.1208/s12249-022-02338-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-022-02338-1