Abstract

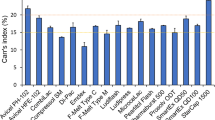

In recent years, orally disintegrating (OD) tablets have been continuously improved to increase efficacy. Herein, we focused on the benefits of cellulose nanofiber (CNF), a highly functional material, in OD tablet manufacturing. We studied its effects on the physical properties of tablets during manufacture. The analyzed tablet formulations included different content CNF (0–50%; 6 preparations), lactose hydrate, acetaminophen, and magnesium stearate (Mg-St). We measured the angles of repose and evaluated the flowability of the powder. Tablets were prepared on a tabletop and rotary tableting presses, whereafter their weight, drug content, hardness, friability, and disintegration time were evaluated. Although CNF addition slightly reduced powder flowability, continuous tableting was feasible via direct powder compression. Tablet hardness (~40 N) was comparable between CNF-containing (20%) tablets and those prepared with crystalline cellulose under 10 kN compression force. Disintegration time (~30 s) was similar between CNF-supplemented tablets and those supplemented with low-substituted hydroxypropyl cellulose, crospovidone, or croscarmellose sodium. At higher CNF fractions, tablet hardness increased, while friability decreased. Adding ≥30% CNF prolonged the tablet disintegration time. To set the optimized manufacturing condition for ensuring the desired tablet physical properties, we created contour plots for evaluating the effects of CNF concentration and compression force on hardness and disintegration time. A CNF concentration of 10–20% and a compression force of 12–13 kN would allow for the preparation of tablets with a hardness ≥30 N and a disintegration time ≤60 s. Altogether, addition of CNF to the OD tablet formulation for direct powder compression enhanced hardness and disintegration.

Similar content being viewed by others

References

Kawashima Y. The Society of Powder Technology, Japan: division of particulate preparation and design, editors. Compression molding technology of powder. Tokyo: Nikkan Kogyo Shimbun, Ltd.; 1998. p. 3–11.

Blanco M, Alcalá M. Content uniformity and tablet hardness testing of intact pharmaceutical tablets by near infrared spectroscopy. Anal Chim Acta. 2006;557:353–9. https://doi.org/10.1016/j.aca.2005.09.070.

Moes JJ, Ruijken MM, Gout E, Frijlink HW, Ugwoke MI. Application of process analytical technology in tablet process development using NIR spectroscopy: blend uniformity, content uniformity and coating thickness measurements. Int J Pharm. 2008;357:108–18. https://doi.org/10.1016/j.ijpharm.2008.01.062.

Goodwin DJ, van den Ban S, Denham M, Barylski I. Real time release testing of tablet content and content uniformity. Int J Pharm. 2018;537:183–92. https://doi.org/10.1016/j.ijpharm.2017.12.011.

Wang X, Cui F, Yonezawa Y, Sunada H. Preparation and evaluation of combination tablet containing incompatible active ingredients. Chem Pharm Bull (Tokyo). 2003;51:772–8. https://doi.org/10.1248/cpb.51.772.

Takeuchi Y, Yoshida M, Ito A, Sunada H. Uniformity of drug content during pharmaceutical dry granulating by roller compaction and tableting processes. J Drug Deliv Sci Technol. 2009;19:119–24. https://doi.org/10.1016/S1773-2247(09)50019-6.

Mahours GM, Shaaban DEZ, Shazly GA, Auda SH. The effect of binder concentration and dry mixing time on granules, tablet characteristics and content uniformity of low dose drug in high shear wet granulation. J Drug Deliv Sci Technol. 2017;39:192–9. https://doi.org/10.1016/j.jddst.2017.03.014.

Sun WJ, Aburub A, Sun CC. Particle engineering for enabling a formulation platform suitable for manufacturing low-dose tablets by direct compression. J Pharm Sci. 2017;106:1772–7. https://doi.org/10.1016/j.xphs.2017.03.005.

Furukawa K. Development of excipients for direct compression by fluidized bed granulation. Pharm Tech Jpn. 2018;34:93–7.

Yoshida I, Sakai Y. The applications of the content uniformity test and the weight variation test on process validation tests of multiple ingredient preparations. Chem Pharm Bull. 1999;47:678–83. https://doi.org/10.1248/cpb.47.678.

Katori N, Aoyagi N, Kojima S. The study of the applicability of content uniformity and weight variation test—the state of commercial tablets and capsules in Japan. Chem Pharm Bull. 2001;49:1412–9. https://doi.org/10.1248/cpb.49.1412.

Lukášová I, Muselík J, Franc A, Goněc R, Mika F, Vetchý D. Factor analysis in optimization of formulation of high content uniformity tablets containing low dose active substance. Eur J Pharm Sci. 2017;109:541–7. https://doi.org/10.1016/j.ejps.2017.09.017.

Makino T. The first of direct compression to accelerate pharmaceutical development and reduce cost of dosage form. Pharm Tech Jpn. 2017;33:2309–11.

Hara Y. Development of direct tableting technology for Pletaal OD tablet. Pharm Tech Jpn. 2017;33:2313–6.

Katayama T, Terasawa K, Takeuchi T, Okuda Y. Formulation design of olanzapine orally disintegration tablet “TOWA”—direct compression—The first choice in the manufacture of tablets. Pharm Tech Jpn. 2017;33:2317–20.

Makino T, Hoshino T, Tsuchiya A, Oneda Y. Analysis and evaluation the super-high speed compression—securing of content uniformity. Pharm Tech Jpn. 2018;34:283–7.

United States Food and Drug Administration. Orally disintegrating tablets. Guidance for industry. Rockville. Maryland: FDA; 2008.

Fu Y, Yang S, Jeong SH, Kimura S, Park K. Orally fast disintegrating tablets: developments, technologies, taste-masking and clinical studies. Crit Rev Ther Drug Carrier Syst. 2004;21:433–76. https://doi.org/10.1615/CritRevTherDrugCarrierSyst.v21.i6.10.

Goel H, Rai P, Rana V, Tiwary AK. Orally disintegrating systems: innovations in formulation and technology. Recent Pat Drug Deliv Formul. 2008;2:258–74. https://doi.org/10.2174/187221108786241660.

Al-Husban FA, El-Shaer AM, Jones RJ, Mohammed AR. Recent patents and trends in orally disintegrating tablets. Recent Pat Drug Deliv Formul. 2010;4:178–97. https://doi.org/10.2174/187221110793237574.

Badgujar BP, Mundada AS. The technologies used for developing orally disintegrating tablets: a review. Acta Pharm. 2011;61:117–39. https://doi.org/10.2478/v10007-011-0020-8.

Namiki N. Clinical functionality required for orally disintegrating tablets selected as the next generation type. YAKUGAKU ZASSHI. 2015;135:237–43. https://doi.org/10.1248/yakushi.14-00228-3.

Okuda Y, Irisawa Y, Okimoto K, Osawa T, Yamashita S. A new formulation for orally disintegrating tablets using a suspension spray-coating method. Int J Pharm. 2009;382:80–7. https://doi.org/10.1016/j.ijpharm.2009.08.010.

Douroumis DD, Gryczke A, Schminke S. Development and evaluation of cetirizine HCl taste-masked oral disintegrating tablets. AAPS PharmSciTech. 2011;12:141–51. https://doi.org/10.1208/s12249-010-9569-7.

Stirnimann T, Di Maiuta ND, Gerard DE, Alles R, Huwyler J, Puchkov M. Functionalized calcium carbonate as a novel pharmaceutical excipient for the preparation of orally dispersible tablets. Pharm Res. 2013;30:1915–25. https://doi.org/10.1007/s11095-013-1034-3.

European Pharmacopoeia (2016) Orodispersible tablets. European directorate for the quality of medicines (EDQM), council of Europe, 8th ed. Strasbourg, France; 2016. p. 811.

Hu X, Li Y, Zhang E, Wang X, Xing M, Wang Q, Lei J, Huang H. Preparation and evaluation of orally disintegrating tablets containing taste-masked microcapsules of berberine hydrochloride. AAPS PharmSciTech. 2013;14:29–37. https://doi.org/10.1208/s12249-012-9880-6.

Kande KV, Kotak DJ, Degani MS, Kirsanov D, Legin A, Devarajan PV. Microwave-assisted development of orally disintegrating tablets by direct compression. AAPS PharmSciTech. 2017;18:2055–66. https://doi.org/10.1208/s12249-016-0683-z.

Ministry of the Environment. Guidelines for the utilization and application of cellulose nanofiber towards the decarbonization and achievement of a circular economy. 2021. http://www.env.go.jp/earth/earth/ondanka/cnf/guideline_summaryen.pdf. Accessed 28 Nov 2021.

The International Organization for Standardization. TS 20477: nanotechnologies–standard terms and their definition for cellulose nanomaterial. ISO. 2017. https://www.iso.org/obp/ui/#iso:std:68153:en. Accessed 28 Nov 2021.

Plackett DV, Letchford K, Jackson JK, Burt HM. A review of nanocellulose as a novel vehicle for drug delivery. Nord Pulp Pap Res J. 2014;29:105–18. https://doi.org/10.3183/npprj-2014-29-01-p105-118.

Lin N, Dufresne A. Nanocellulose in biomedicine: current status and future prospect. Eur Polym J. 2014;59:302–25. https://doi.org/10.1016/j.eurpolymj.2014.07.025.

Svagan AJ, Benjamins JW, Al-Ansari Z, Shalom DB, Müllertz A, Wågberg L, et al. Solid cellulose nanofiber based foams –towards facile design of sustained drug delivery systems. J Control Release. 2016;244:74–82. https://doi.org/10.1016/j.jconrel.2016.11.009.

Bannow J, Benjamins JW, Wohlert J, Löbmann K, Svagan AJ. Solid nanofoams based on cellulose nanofibers and indomethacin—the effect of processing parameters and drug content on material structure. Int J Pharm. 2017;526:291–9. https://doi.org/10.1016/j.ijpharm.2017.04.041.

Löbmann K, Svagan AJ. Cellulose nanofibers as excipient for the delivery of poorly soluble drugs. Int J Pharm. 2017;533:285–97. https://doi.org/10.1016/j.ijpharm.2017.09.064.

Kargarzadeh H, Mariano M, Huang J, Lin N, Ahmad I, Dufresne A, Thomas S. Recent developments on nanocellulose reinforced polymer nanocomposites: a review. Polymer. 2017;132:368–93. https://doi.org/10.1016/j.polymer.2017.09.043.

Sharip NS, Ariffin H. Cellulose nanofibrils for biomaterial applications. Mater Today Proc. 2019;16:1959–68. https://doi.org/10.1016/j.matpr.2019.06.074.

Meneguin AB, da Silva BH, Sábio RM, de Sousa PZ, Manieri KF, de Freitas LAP, et al. Spray-dried bacterial cellulose nanofibers: a new generation of pharmaceutical excipient intended for intestinal drug delivery. Carbohydr Polym. 2020;249:116838. https://doi.org/10.1016/j.carbpol.2020.116838.

Liu S, Qamar SA, Qamar M, Basharat K, Bilal M. Engineered nanocellulose-based hydrogels for smart drug delivery applications. Int J Biol Macromol. 2021;181:275–90. https://doi.org/10.1016/j.ijbiomac.2021.03.147.

Raghav N, Sharma MR, Kennedy JF. Nanocellulose: a mini-review on types and use in drug delivery systems. Carbohydr Polym Technol Appl. 2021;2:100031. https://doi.org/10.1016/j.carpta.2020.100031.

The Japanese Pharmacopoeia. General information, tablet hardness test. The Japanese Pharmacopoeia. Ministry of Health, Labour and Welfare, 18th ed; 2021. p 2641‒2 http://www.mhlw.go.jp/content/11120000/000788362.pdf.

The Japanese Pharmacopoeia. General information, tablet friability test. The Japanese Pharmacopoeia. Ministry of Health, Labour and Welfare, 18th ed; 2021. p. 2642. https://www.mhlw.go.jp/content/11120000/000788362.pdf.

The Japanese Pharmacopoeia. General tests, processes and apparatus, uniformity of dosage units. The Japanese Pharmacopoeia. Ministry of Health, Labour and Welfare, 18th ed; 2021. p. 147‒9. https://www.mhlw.go.jp/content/11120000/000788359.pdf.

Guilford JP. Fundamental statistics in psychology and education. New York: McGraw-Hill; 1956.

Carr RL. Evaluating flowability properties of solids. Chem Eng. 1965;18:163–8.

Acknowledgements

The authors thank Daio Paper Corp. for providing cellulose nanofiber.

Author information

Authors and Affiliations

Contributions

S. N. wrote the manuscript and designed experiments. T. F. carried out the tableting experiment. T. S. designed the experiments. All the authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nakamura, S., Fukai, T. & Sakamoto, T. Orally Disintegrating Tablet Manufacture via Direct Powder Compression Using Cellulose Nanofiber as a Functional Additive. AAPS PharmSciTech 23, 37 (2022). https://doi.org/10.1208/s12249-021-02194-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-021-02194-5